A Method for Effectively Monitoring the Running Effect of Pickling Anti-Wrinkle Roller

An anti-wrinkle roller and pickling technology, which is applied in the field of effectively monitoring the operation effect of pickling and anti-wrinkle rollers, can solve problems such as the inability to use the anti-wrinkle roller, and achieve the effects of avoiding long-term downtime, slowing down wear and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

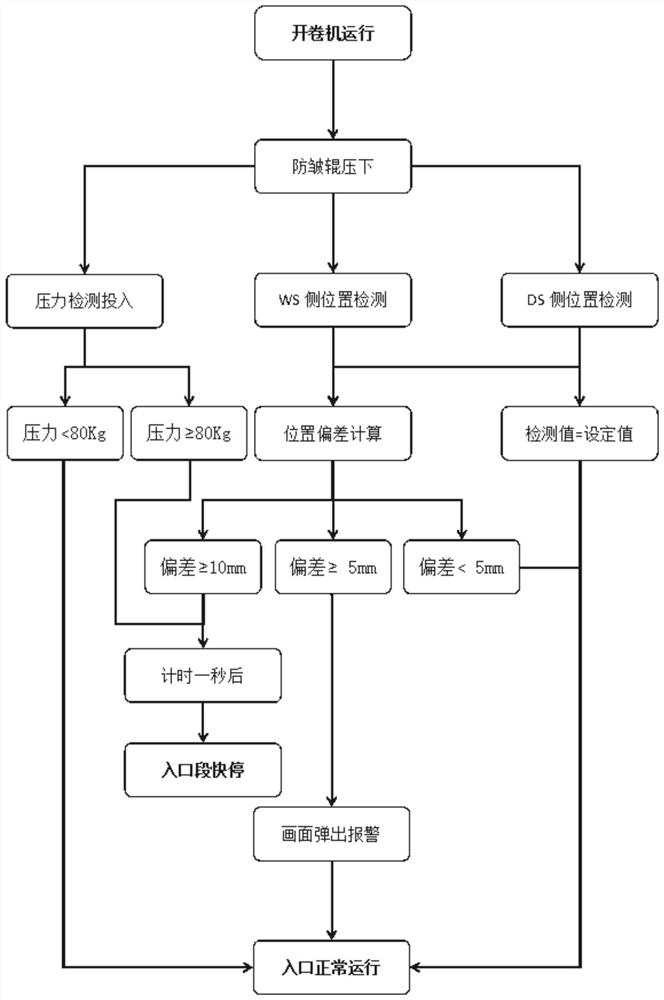

[0031] Embodiment 1: see Figure 1-Figure 4 , a method for effectively monitoring the running effect of pickling anti-wrinkle rolls, said method comprising the following steps:

[0032] 1) The uncoiler is running,

[0033] 2) The anti-wrinkle roller is pressed down,

[0034] 3) Pressure detection, WS side position detection, DS side position detection input,

[0035] 4) Pressure detection input, the detection pressure value is <80Kg, the value of the position closed-loop encoder on the DS side = the set value of the pressure, and the inlet is operating normally.

[0036] 5) The input detection pressure of pressure detection is less than 80Kg, the calculation deviation of the position deviation between the DS side and the WS side is less than 5mm, and the inlet is in normal operation;

[0037] 6) Pressure detection input detection pressure < 80Kg, position deviation calculation deviation between DS side and WS side [5mm, 10mm), the screen pops up an alarm prompting that the ...

Embodiment 2

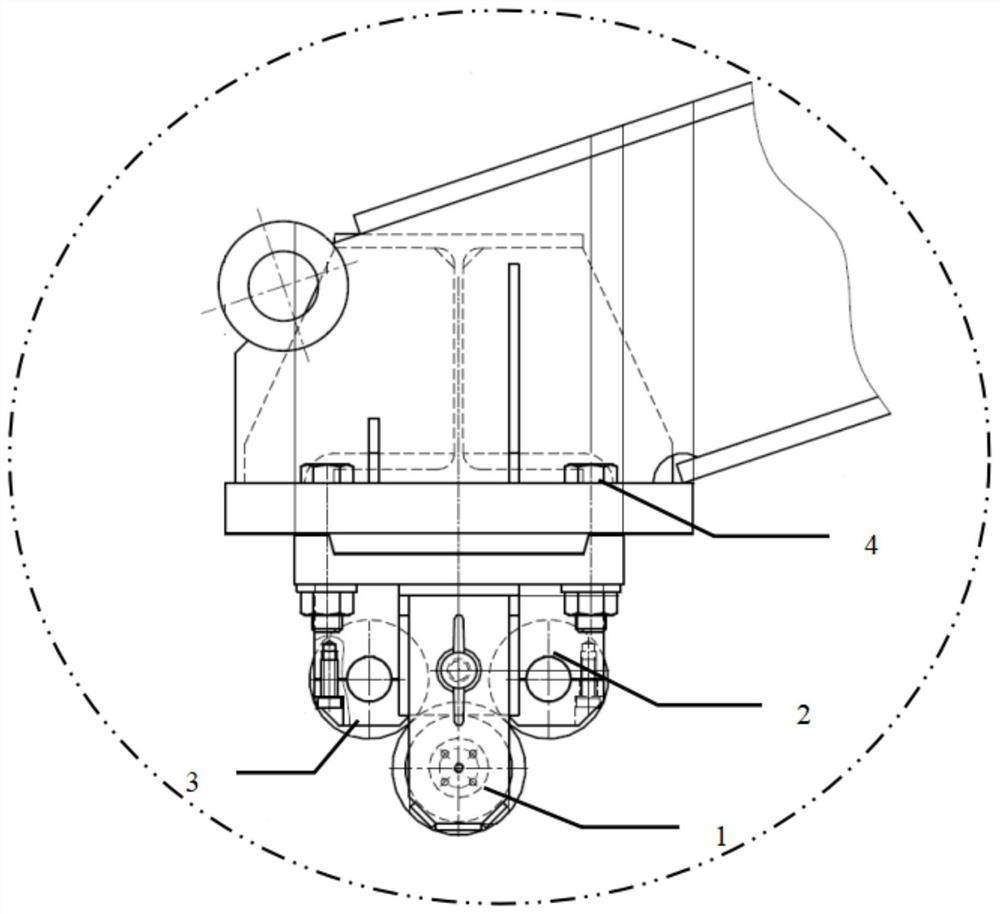

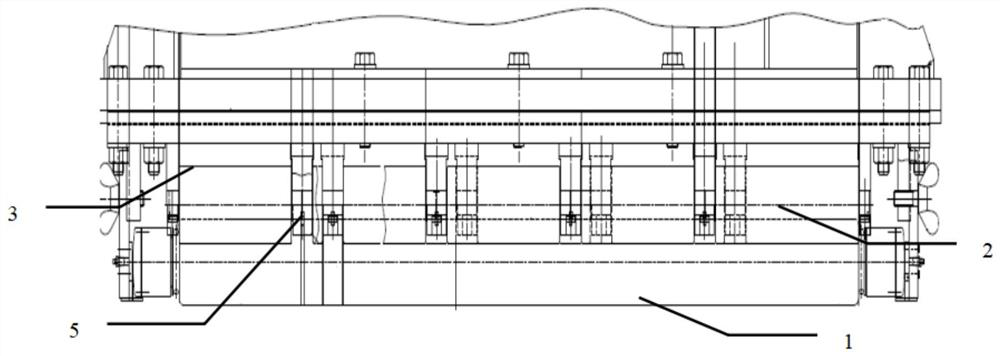

[0046] Example 2: see 2- Figure 4 , a device for effectively monitoring the operation of the pickling anti-wrinkle roll, the device includes an anti-wrinkle roll 1, a support roll 2, a support roll 3, a connecting bolt 4, a bearing seat 5, an encoder 6, an anti-wrinkle roll oil cylinder 7, a connecting Pin 8, support frame 9, swing frame 10, swing shaft 11, pressure roller 12, pressure roller swing bracket 13, pressure roller cylinder 14 and steel coil 15, and the pressure roller 12 is connected to the pressure roller cylinder 14 through the pressure roller swing bracket 13 , the anti-wrinkle roller cylinder 7 is arranged on the support frame 9, the swing shaft 11 is connected to the swing frame 10, and the support roller 3 and the support roller 2 are fixed on the bearing housing 5 by connecting bolts.

[0047] Work process: before the uncoiler runs, the pressure roller 12 is lifted by the pressure roller cylinder 14 and the pressure roller swing bracket 13, then the uncoile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com