Turbofan engine inlet part ice ball collision device

A turbofan and engine technology, which is applied in gas turbine engine testing, jet engine testing, etc., can solve the problem of not giving simulated ice cubes or birds hitting turbofan engines, and achieves easy implementation, high reliability, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

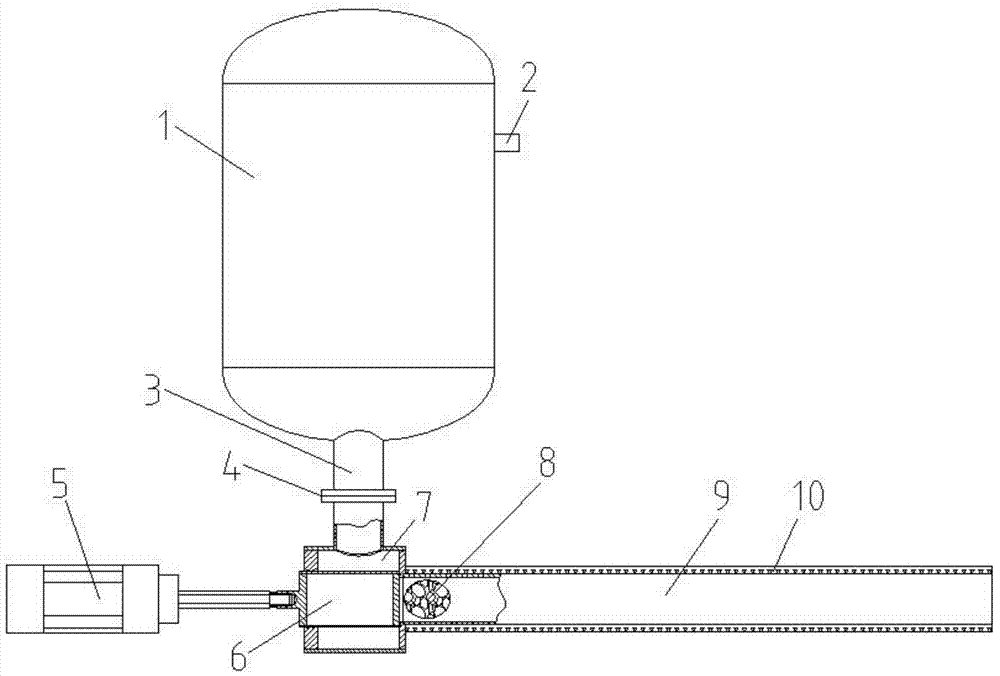

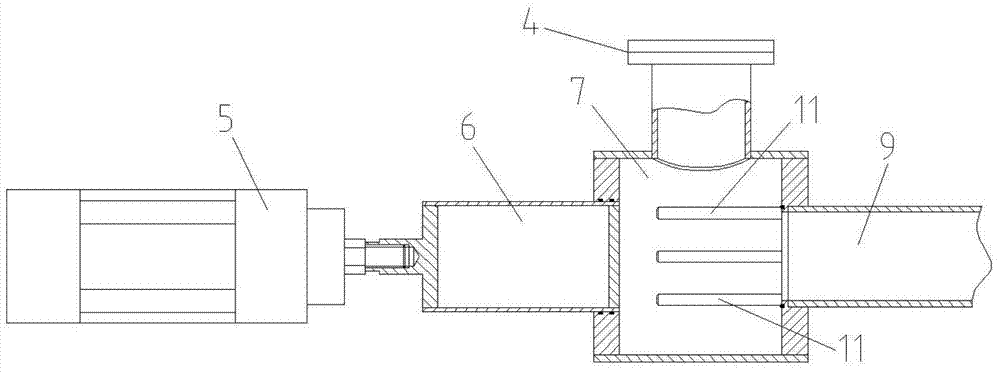

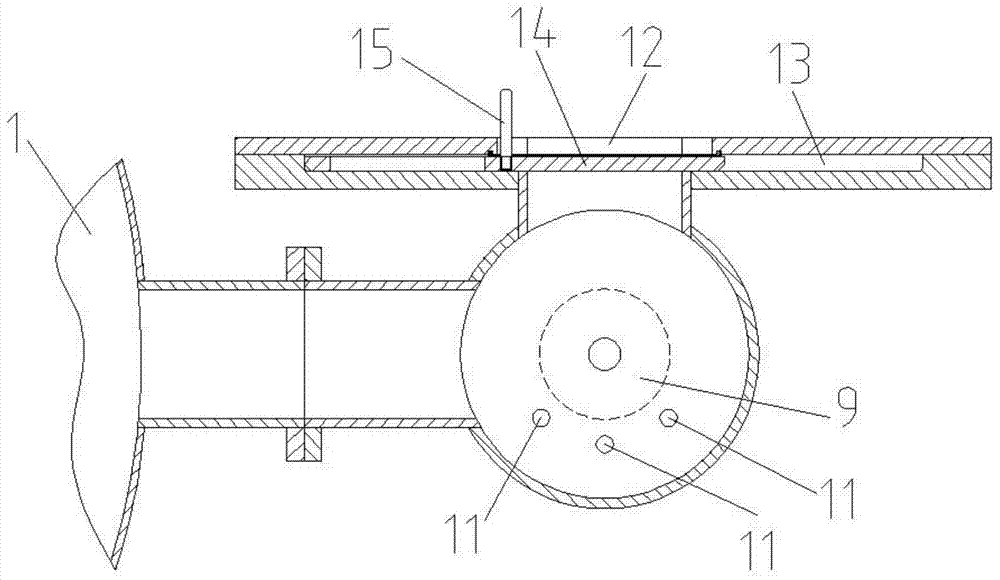

[0019] Examples of the present invention are Figure 1 to Figure 4 As shown, the present invention includes a high-pressure gas storage tank 1, a high-pressure gas inlet pipe 2, a high-pressure gas outlet pipe 3, a flange 4, a locking cylinder 5, a sliding valve in a cabin 6, an ice bomb filling launching cabin 7, an ice bomb 8, Ice bomb launch tube 9, heat insulation material 10, ice bomb support rod 11, ice bomb inlet 12, sliding valve groove 13, ice bomb inlet sliding valve 14 and handle 15, air outlet of high-pressure gas inlet pipe 2, high-pressure gas outlet pipe The air inlets of 3 are all connected with the high-pressure gas storage tank 1, the air inlet of the high-pressure gas inlet pipe 2 is connected with the air outlet of the compressor, and the air outlet of the high-pressure gas outlet pipe 3 fills the launch chamber with the ice bomb through the flange 4 The air inlets of 7 are connected together, the entrance of the ice bomb launching tube 9 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com