Hot rubber sheet rapid cooling system

A rubber sheet and operating system technology, which is applied in the field of rubber processing, can solve the problems of large amount of regular water treatment, large workshop area, and large power consumption, and achieve the effects of reducing power consumption, investment, and waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

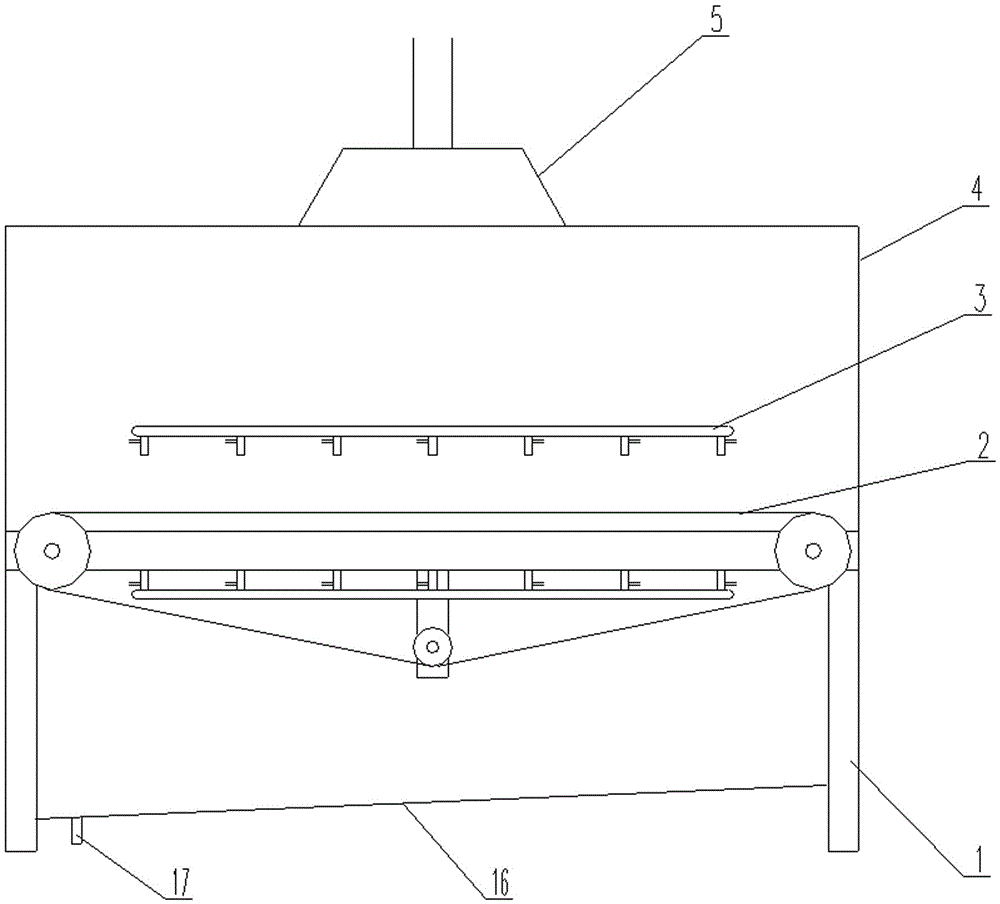

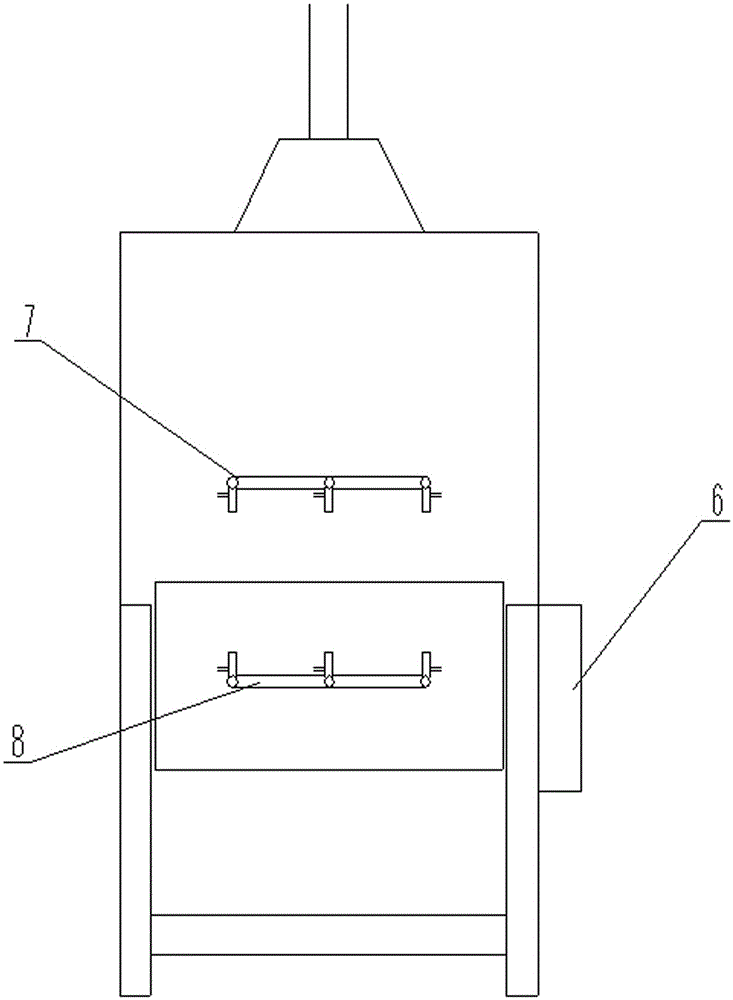

[0037] see figure 1 , figure 2 , image 3 .

[0038] This hot rubber rapid cooling system includes a frame 1, a conveying device 2 for conveying hot rubber sheets, a spray device 3, an isolation cover 4 for separating the conveying device 2 and spray device 3 from the ambient atmosphere, and an exhaust device 5 and control section 6,

[0039] The spraying device 3 includes more than one independent spraying pipeline and nozzles arranged on the spraying pipeline, and the spraying pipeline has an upper spraying pipeline 7 and a lower spraying pipeline 8 .

[0040] The isolation cover 4 is fixedly connected with the frame 1 and has an opening through which the hot rubber sheet for conveying passes.

[0041] The exhaust device 5 is fixedly connected above the isolation cover 4,

[0042] A liquid collection tray 16 and a drain pipe 17 connected to the bottom of the liquid collection tray 16 are arranged at the bottom of the frame 1. The collection tray 16 is made of metal mat...

Embodiment 2

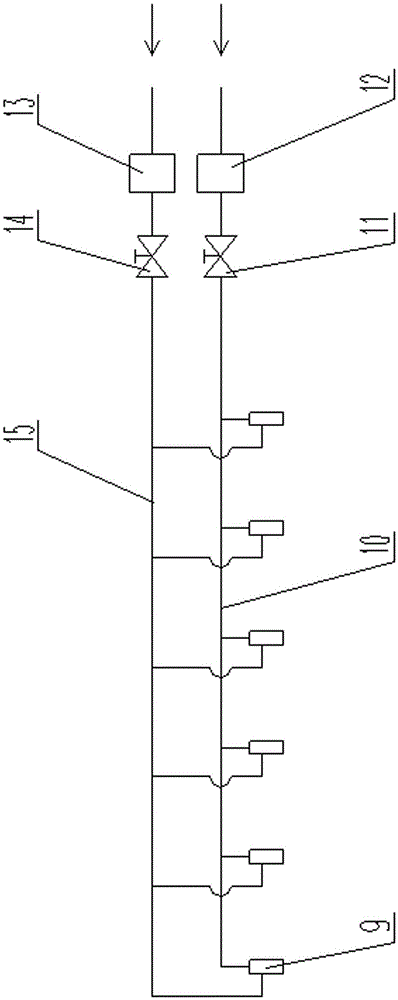

[0060] see figure 1 , figure 2 , Figure 4 .

[0061] The present embodiment is the same as the embodiment 1 except that the spraying device is different from the embodiment 1. In this embodiment, the nozzle of the spraying device 3 is sprayed with a liquid pressurized single-fluid nozzle 21, and the high-pressure water is used to pass through the flow obstacle to change the hydrodynamic properties of the aerosol flow discharged from the spray head, so that the water is atomized into small Single-fluid nozzle for water droplets. The pressure of the high-pressure water is 3-20 MPa, preferably 4-15 MPa.

[0062] This spraying device 3 comprises water tank 18, booster pump 19, control valve 14, high-pressure delivery pipe 20, nozzle 21; The operating system 6 is respectively connected to a booster pump 19 and a control valve 14 .

[0063] The control valve 14 is a solenoid valve.

[0064] The spraying device 3 also includes a liquid filter 13 , and the liquid filter 13 is...

Embodiment 3

[0071] This embodiment is similar to Embodiment 1, except that the liquid supply of the two-fluid nozzle is a siphon type that uses compressed air force to suck the liquid onto the spray, and the water source is the clean water in the water tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com