A cooling system for wood-plastic process

A cooling system and process technology, applied in the field of cooling mold devices, can solve the problems of high cost of cooling methods, the inability to omit the cooling section, and poor cooling effect of the air cooling section, so as to ensure the quality of the workpiece and reduce the cooling length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

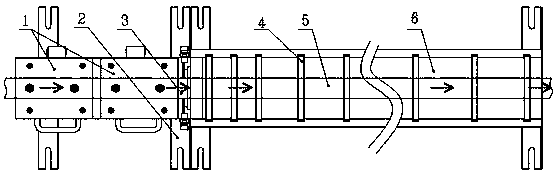

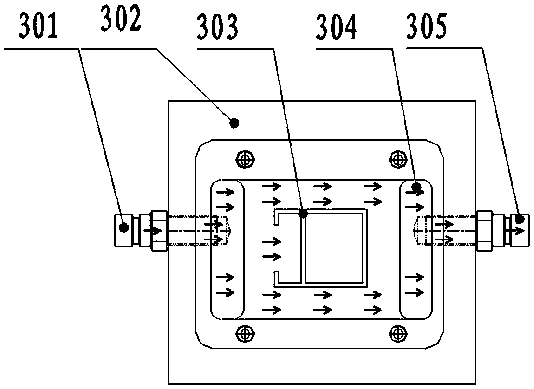

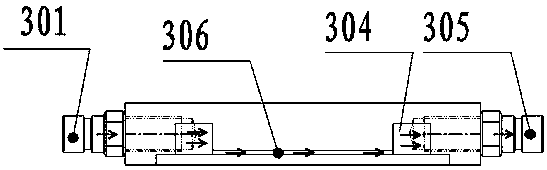

[0025] Figure 1-4 As shown, the specific implementation is as follows:

[0026] A cooling system for wood-plastic process, including cooling module 1 of shaping section, cooling module 3 of isolation section and water cooling module arranged in sequence, cooling module 1 of shaping section accepts extruder to facilitate rapid cooling and molding of workpieces, and the end of water cooling module A tractor is connected to facilitate the dynamic transmission of workpieces between the cooling module 1 of the shaping section, the cooling module 3 of the isolation section and the water cooling module. The modules are separated from each other to prevent the cooling water of the water-cooling module from affecting the cooling module of the shaping section. The cooling module 3 of the isolation section includes at least one water-cooling sealing plate, which surrounds the workpiece through the water-cooling sealing plate to prevent its contact with air from affecting the cooling eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com