Cooling device of extrusion master batch

A technology of cooling device and masterbatch, which is applied in the field of extrusion masterbatch cooling device, can solve the problems of poor cleaning of material accumulation, reduction of masterbatch mechanical properties, material bending and other problems, so as to achieve no impact on product performance, shorten cooling length, Increased cooldown effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

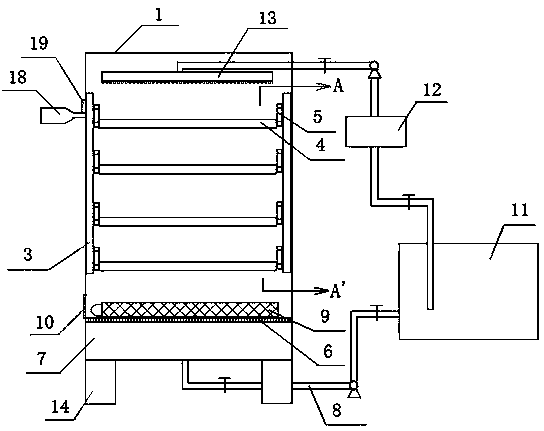

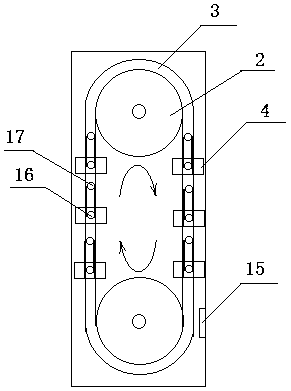

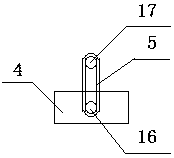

[0025] The present invention is a cooling device for extrusion masterbatch. The cooling space of the device is placed in a box body 1, and a set of drive wheels 2 are arranged on the left and right side walls of the box body 1, and each side of the drive wheel 2 is an upper In one arrangement, the transmission wheel is electrically connected to the motor, and the transmission wheels 2 on each side are connected through a transmission chain 3. The transmission chain 3 can be a transmission chain or a solid rubber belt, as long as its side can be fixed The main transmission chain protrusion 7 gets final product. The opposite sides of the transmission chain 3 are respectively provided with symmetrical transmission chain protrusions 17 from top to bottom, and the outside of the transmission chain protrusions 17 can be threaded to connect the retaining pieces, and between the symmetrical positions of the left and right transmission chains 3 Horizontal cooling groove 4, described co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com