A testing tool for touch device functionality and performance

A technology for testing tools and equipment functions, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., it can solve the problems of human-like multi-finger operation and testing difficulties, test difficulties, etc., to improve test efficiency, improve test efficiency, and improve execution. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

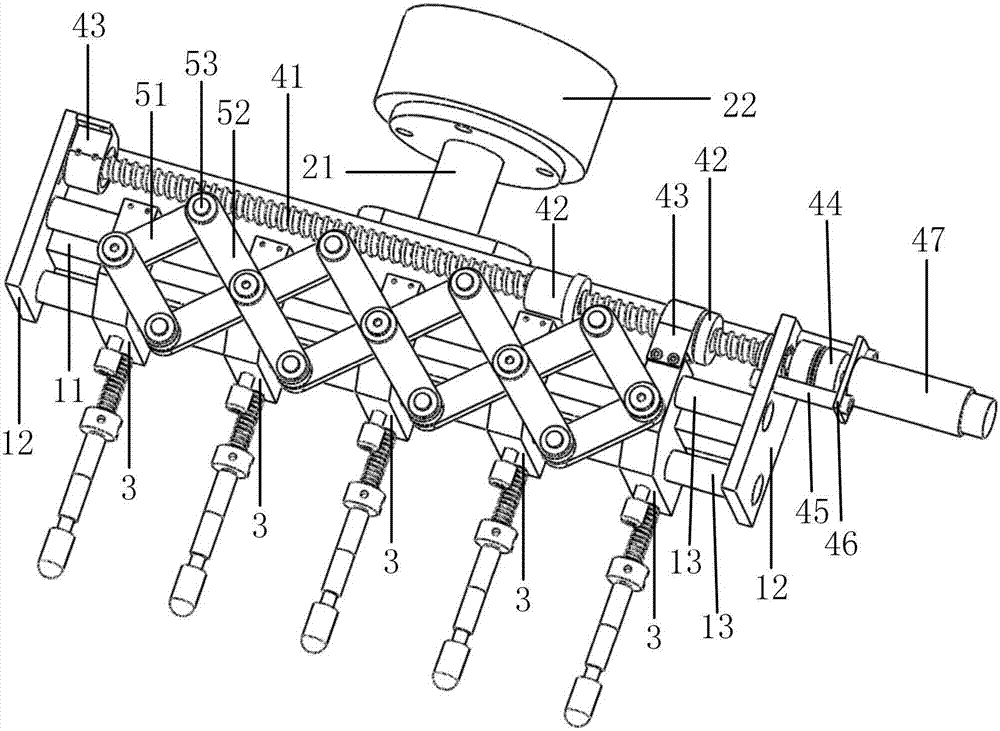

[0059] see figure 1 , the test tool used for the function and performance of the touch device is composed of a base component, a sensor component, a multi-finger module component, a drive component and a grid-like connecting rod telescopic mechanism, and is characterized in that: the base component is each of the test tool The substrate on which the components are installed is equipped with a sensor assembly, a multi-finger module assembly and a drive assembly, the sensor assembly is used for contact force measurement during touch testing, the multi-finger module assembly is used for performing touch operations between the test tool and the touch device, and the drive The assembly is used to drive the movement of the multi-finger module assembly on the base assembly, and the telescoping mechanism of the grid-shaped connecting rod is installed on the multi-finger module assembly for transmission between the multi-finger module assemblies.

Embodiment 2

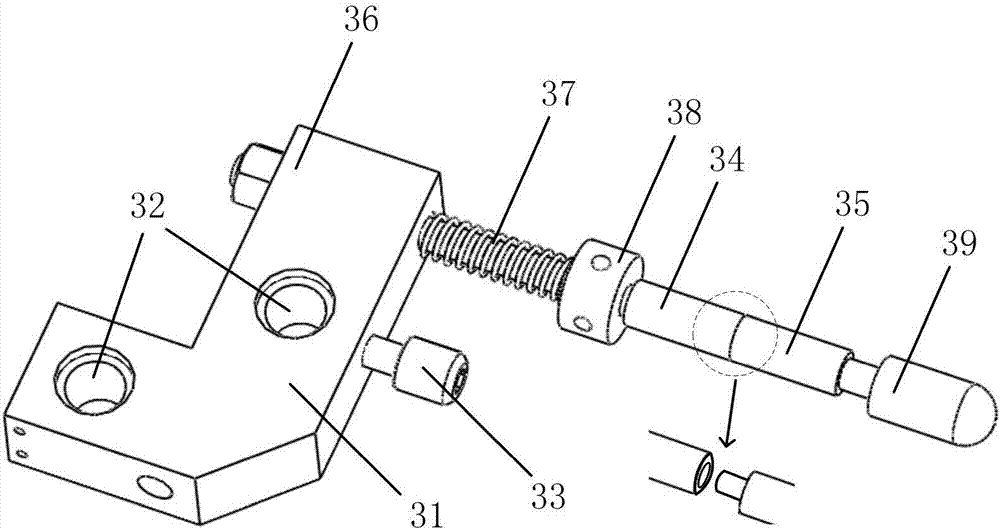

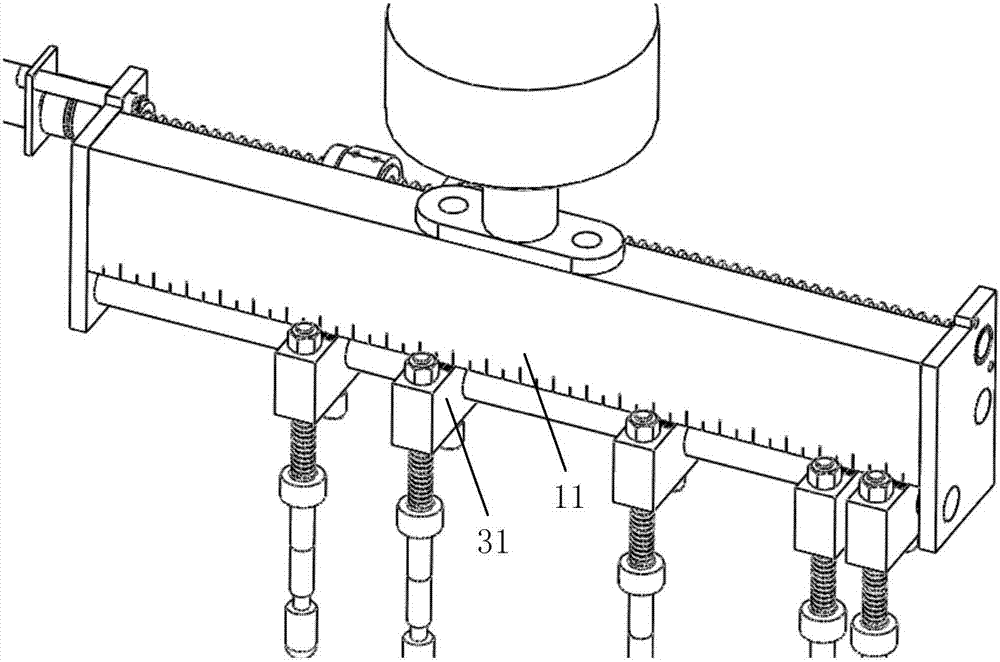

[0061] This embodiment is basically the same as Embodiment 1, and the special feature is: the base assembly is composed of a reference column, two side cover plates and two guide shafts, wherein there is a scale or a scale on the reference column, and the two side covers The plates are installed on both sides of the reference column, and the area of the side cover is larger than the section of the reference column. Two guide shafts are installed between the two side cover plates parallel to the reference column, and the two guide shafts maintain an effective distance. The sensor assembly is composed of a sensor connector and a multi-axis force sensor, wherein the sensor connector is used to connect the multi-axis force sensor to the reference column, and the multi-axis force sensor is not only used to measure the contact force between the test tool and the touch device , and connect the entire test tool to the motion platform. The multi-finger module assembly is composed of ...

Embodiment 3

[0063] figure 1 Shown is a schematic diagram when the number of finger modules in the testing tool for the function and performance of the touch device is five, which is referred to as the five-finger tool here. The five-finger tool is composed of a base assembly, a sensor assembly, a multi-finger module assembly, a drive assembly and a grid-shaped connecting rod telescopic mechanism.

[0064] figure 1 The base assembly shown is the reference for installation of other components of the five-finger tool, and the assembly includes a reference column 11 , two side cover plates 12 and two guide shafts 13 . The reference column 11 is made of an aluminum alloy profile with a rectangular cross-section, which greatly reduces the weight of the five-finger tool while ensuring strength. The guide shafts 13 are respectively arranged on the two sides of the aluminum alloy profile to ensure the compactness of the space.

[0065] figure 1 The sensor assembly shown is used to measure the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com