Ship type structure

A ship type and trimaran technology, applied in ship accessories, ships, cargo loading and unloading equipment, etc., can solve the problems of loading and unloading, large space occupation, high cost, etc., and achieves a small hull heel angle, good righting ability, and good sailing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

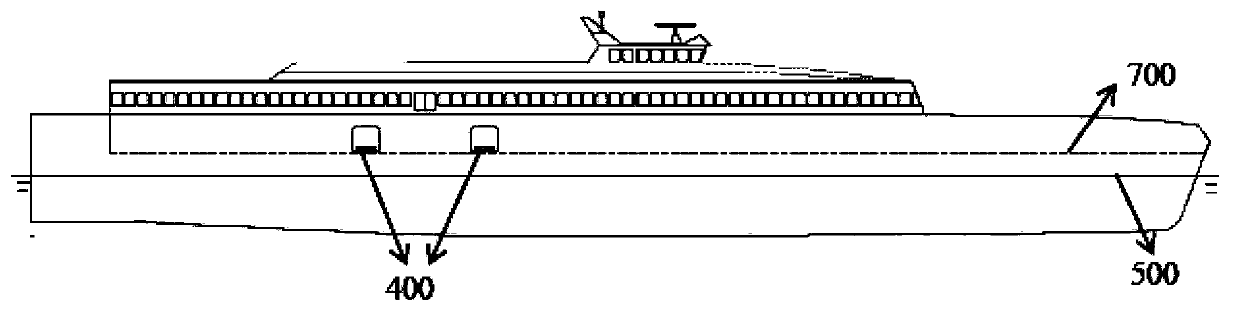

[0024] The structures of the embodiments of the present invention will be further described in detail below with reference to the drawings. figure 1 It is a side view of an embodiment of the present invention. Depend on figure 1 It can be seen that the side of the ship is provided with a cargo loading and unloading port 400, so that the goods can enter and exit on the side of the ship. When the ship is docked at a wharf with a straight-line design on the land side, it can be docked in the way of side berthing wharf, which is convenient for loading and unloading goods, figure 1 The dotted line in is the cargo deck 700, and the solid line below the dotted line is the waterline 500 at the design draft.

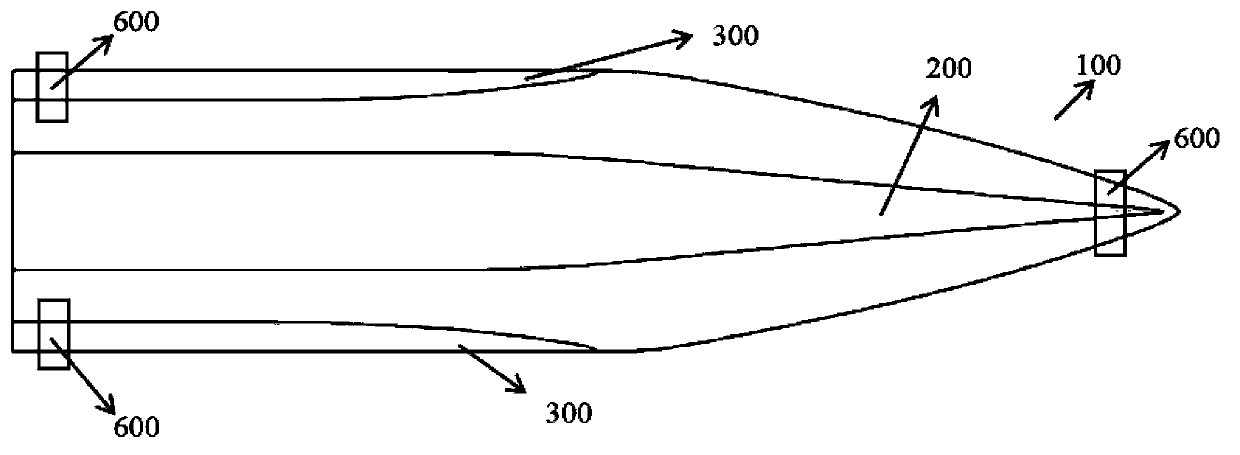

[0025] figure 2 It is a schematic top view of an embodiment of the present invention. figure 2 It shows that the trimaran 100 is formed by connecting the main body 200 and the two side bodies 300 in the present invention, and the two side bodies 300 are respectively located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com