A conveyor chain for the cooling frame of the normalizing furnace

A technology for conveying chains and cooling racks, which is applied in the field of normalizing furnace equipment production, which can solve the problems of inability to convey, insignificant cooling effect, poor thermal conductivity of carbon steel wires, etc., and achieve good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

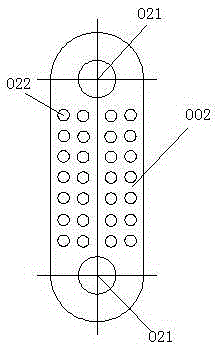

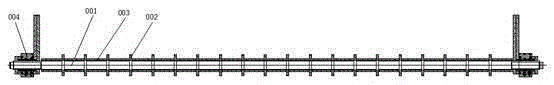

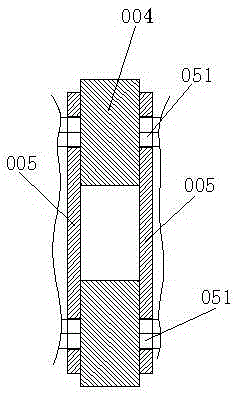

[0015] A conveying chain for a cooling frame of a normalizing furnace, the conveying chain is horizontally arranged in the furnace body, one end protrudes from the feed port, and the other end protrudes from the discharge port, and the conveying chain includes a plurality of piercing shafts 001 arranged in parallel, and piercing shafts The chain plate 002 hinged by the mandrel 001, the spacer 003 sleeved on the mandrel 001, and the sleeves 004 coaxial with the mandrel 001 at both ends of the mandrel 001, the chain plate 002 is a round rectangular plate Body, with symmetrical through holes 021 at both ends, one end through hole 021 is set on a through mandrel 001, the other end through hole 021 is set on the adjacent through mandrel 001, and the spacer 003 is used between adjacent chain plates 002 Separated from each other, the upper chain plates 002 of the adjacent through-core shafts 001 are arranged in a staggered manner. The chain plate 002 is martensitic stainless steel. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com