High-elasticity rubber waterproof paint and preparation method thereof

A waterproof coating and rubber technology, applied in fireproof coatings, asphalt coatings, coatings, etc., can solve problems such as environmental pollution, achieve excellent waterproof performance, save gas energy, and maintain integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: a kind of preparation method of high-elastic rubber waterproof coating, each component and its corresponding parts by weight are as shown in Table 1, and comprise the following steps:

[0069] Step 1: Add petroleum asphalt into an emulsification pot, heat, melt and dehydrate, wait until the temperature drops to 130-150°C, slowly add octadecyl fatty alcohol, glyceryl monostearate and leveling agent under stirring to melt , remove impurities sinking into the bottom of the emulsification pot during heating and melting, keep warm at 120°C, add light stabilizer, toughening agent and coupling agent in sequence, and stir evenly to obtain the first mixture;

[0070] Step 2: Add water into another emulsification pot, raise the temperature to 60°C, add sodium lauryl sulfate and anionic emulsifier under stirring, and dissolve them evenly, then slowly add them under high-speed stirring at a temperature of 120°C °C, stir for 5 minutes to emulsify the first mixture, the...

Embodiment 2-10

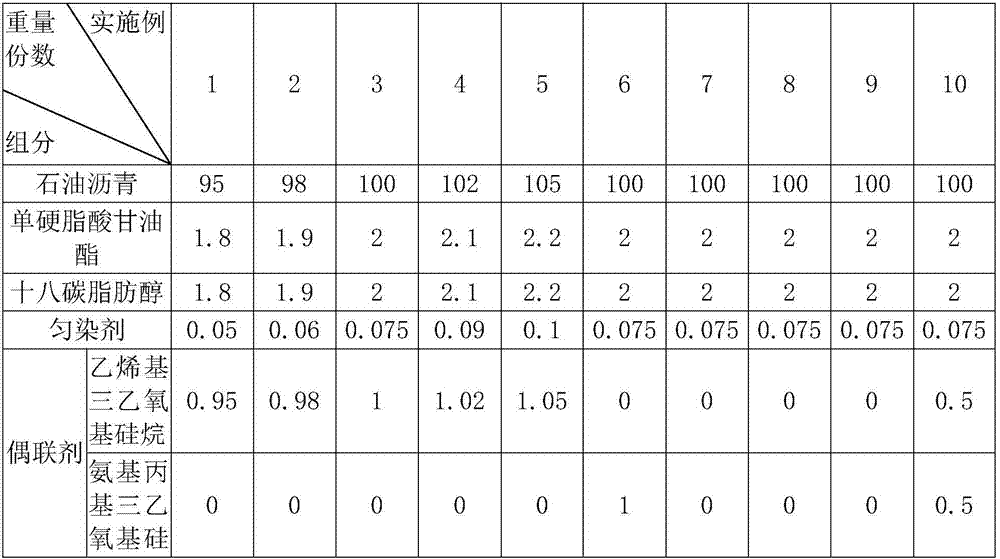

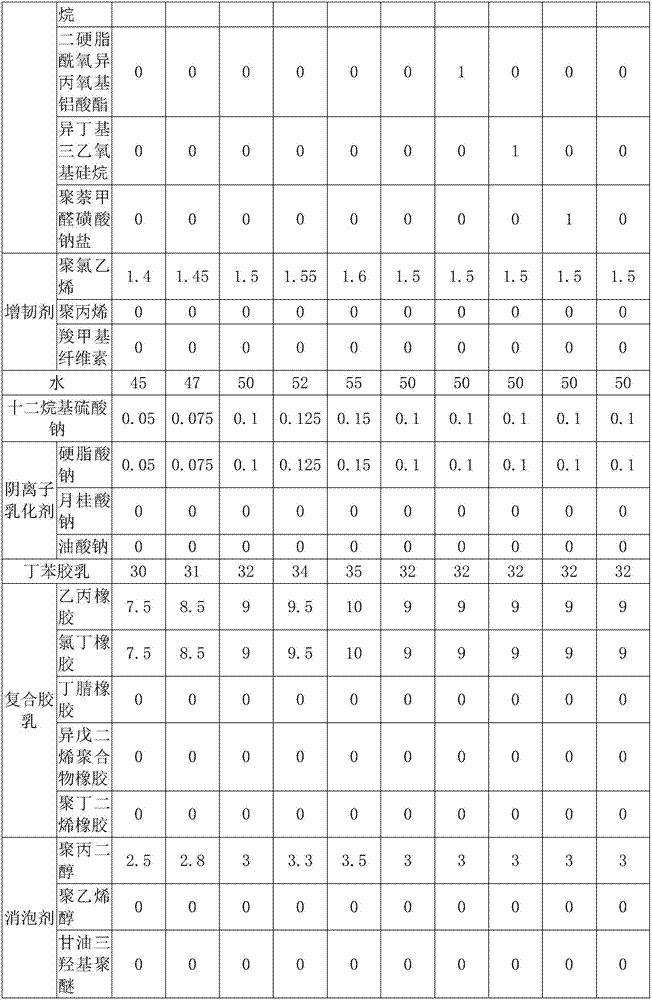

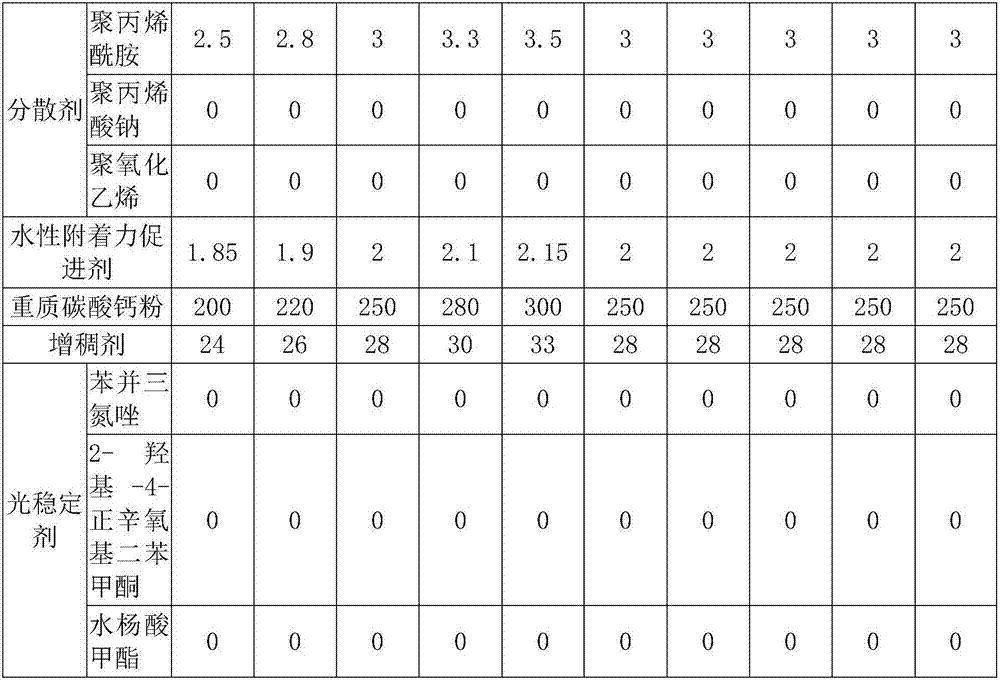

[0073] Example 2-10: A high-elastic rubber waterproof coating, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0074] Each component and parts by weight thereof in table 1 embodiment 1-10

[0075]

[0076]

[0077]

Embodiment 11-20

[0078] Examples 11-20: a high elastic rubber waterproof coating, the difference from Example 3 is that each component and its corresponding parts by weight are shown in Table 2.

[0079] Each component and parts by weight thereof in table 2 embodiment 11-20

[0080]

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com