Automatic lubrication device for vertical reducer

An automatic lubrication and reducer technology, which is applied in the directions of transmission parts, gear lubrication/cooling, belt/chain/gear, etc., and can solve the problem that the top bearing and accessories of the vertical shaft reducer are not easy to lubricate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

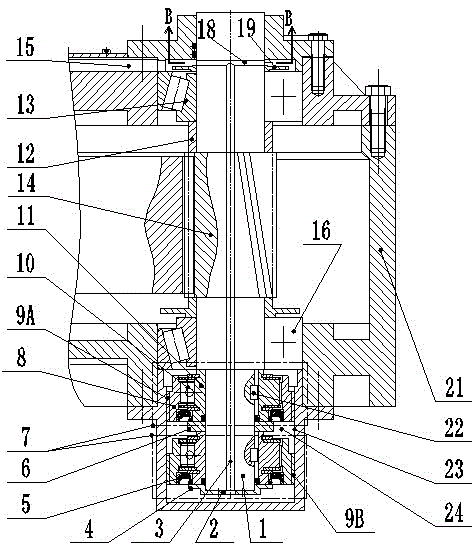

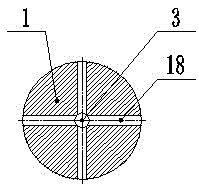

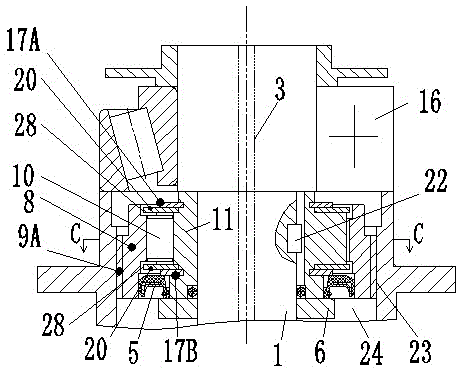

[0020] Depend on Figure 1-Figure 6 The automatic lubricating device of the vertical reducer shown includes a case 21, which is provided with an oil chamber 24 and a vertical shaft 1, and the shaft 1 is vertically arranged, the oil chamber 24 is located at the lower end of the case 21, and the shaft 1 The lower end of the lower end is inserted in the oil chamber 24, and the bottom of the rotating shaft 1 stretching into the oil chamber 24 is provided with two one-way rotating mechanisms 7 up and down. The rotating shaft 1 is sequentially provided with an oil retaining pan 19, an upper bearing 13, a first annular spacer 12, a gear 14, a second annular spacer, a lower bearing 16, a one-way rotation mechanism 7 on the upper side, The spacer ring 6, the one-way rotation mechanism 7 located on the lower side, and the bottom end cover 4 buckled on the bottom end of the rotating shaft 1 .

[0021] The rotating shaft 1 is provided with an oil delivery hole, and the oil delivery hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com