Lock cylinder

A technology of lock head and lock cylinder, which is applied in the direction of building locks, buildings, building structures, etc. It can solve problems such as difficulty in unlocking, falling, and poor lock head anti-theft performance, and achieve good lubrication effect and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

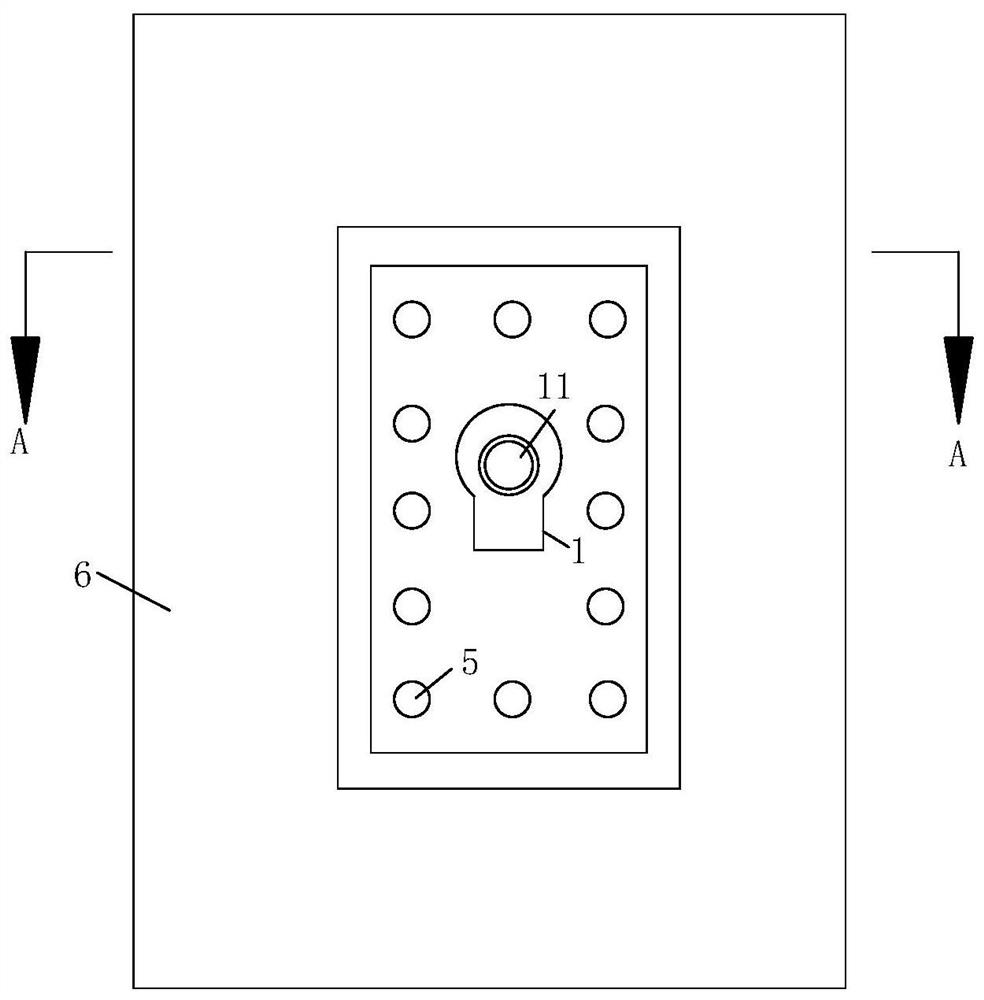

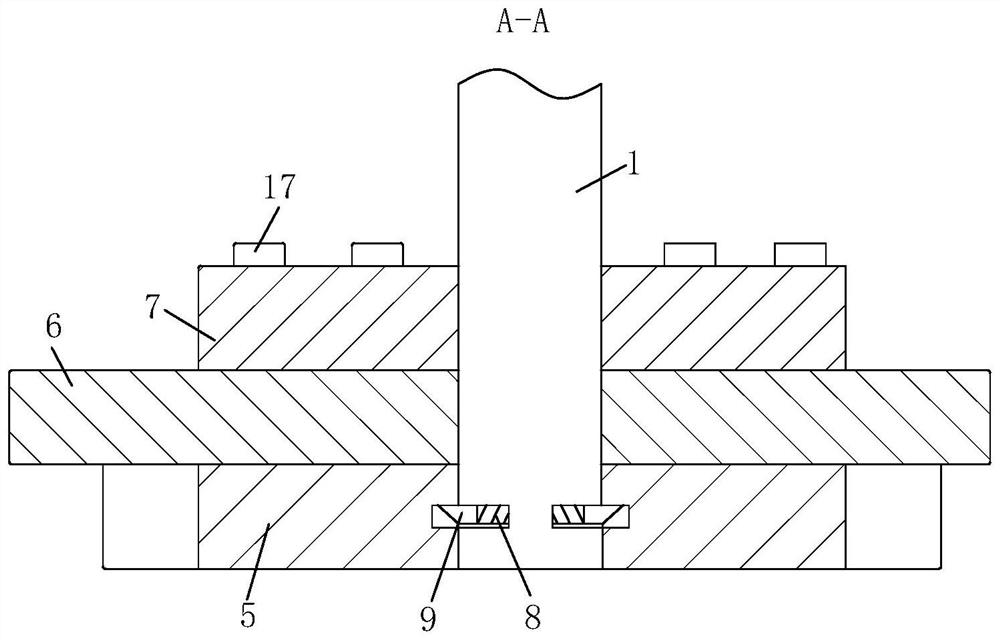

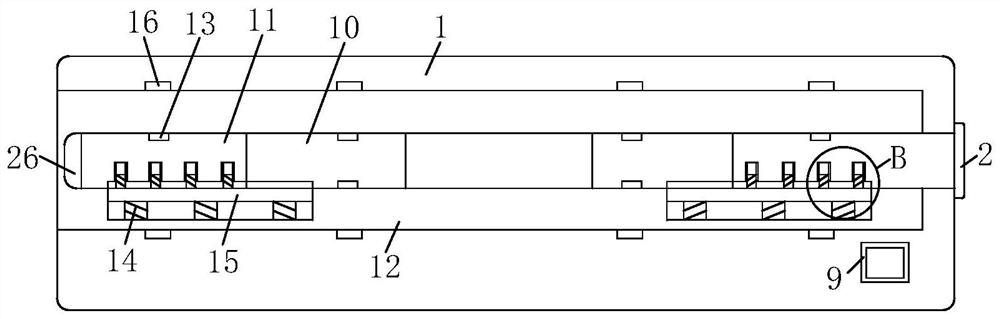

[0038] As a specific embodiment of the present invention, it also includes multiple sets of fixing screws 17, and multiple sets of fixing screws 17 screw-mount the inner fixing plate 7 and the outer door panel; by adopting the above technical scheme, the fixing screws 17 will The inner fixing plate 7 is fixedly connected with the outer door panel, which enhances the stability and safety of the lock head.

[0039] During use, the outer fixing plate 5 is riveted with the door outer plate 6, and the clamping spring 8 makes the block 9 stretch into the fixing hole. The inner fixing plate 7 connected to the front of the lock body 1 is closely attached to the door outer panel 6, and the lock head and the door panel can be fixedly installed to prevent the lock cylinder panel from being damaged. When the hole forcibly rotates the lock cylinder, because the tool cannot perfectly cooperate with the lock cylinder, the multiple groups of marbles 3 will not all shrink back to the lock hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com