Clamping device of tensile testing machine suitable for plate-shaped samples

A technology of tensile testing machine and clamping device, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of small initial clamping force and limitation of clamping efficiency, and achieve enlarged clamping torque and reliable self-locking performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

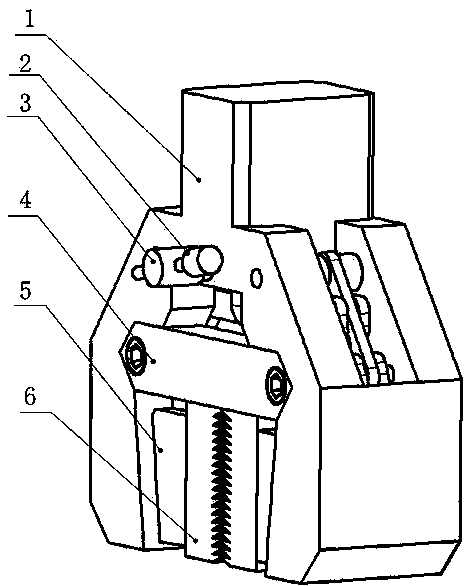

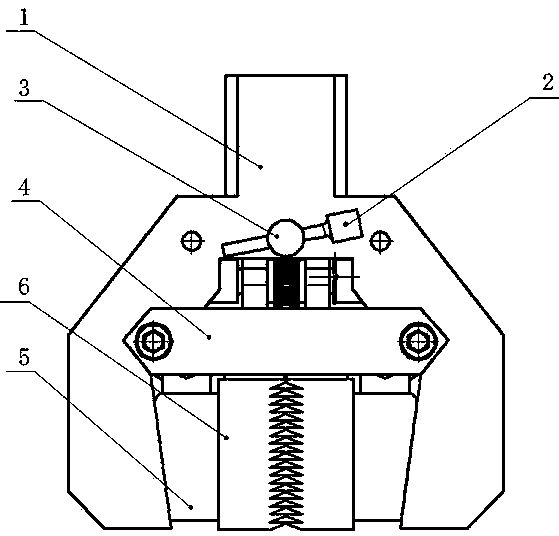

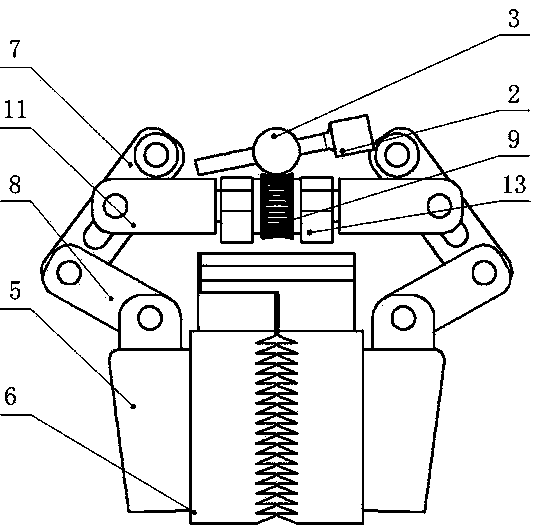

[0022] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 5 As shown, the tensile testing machine clamping device suitable for plate samples of the present invention includes a worm gear retraction mechanism, a connecting rod amplification mechanism and a wedge clamping mechanism, and the worm gear retraction mechanism adopts a bidirectional internal thread The worm gear drives the connecting rods on both sides to perform contraction movement, and the wedge-shaped clamping block of the wedge-shaped clamping mechanism is pushed down by the connecting rod amplification mechanism to clamp the sample.

[0024] The worm gear retraction mechanism is mainly composed of a handle 2, a worm shaft 3, a worm 9 and a worm connector 10. The manual clamping torque is transmitted to the worm 9 through the worm shaft 3 matched with the handle 2, and the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com