A method for repairing cracks in wooden structures using fiber-reinforced concrete

A technology of fiber concrete and wood structure, applied in building maintenance, building structure, construction, etc., can solve problems such as high cost, affecting flatness, affecting the appearance of wood structures, etc., to improve tensile capacity, ensure authenticity, The effect of easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

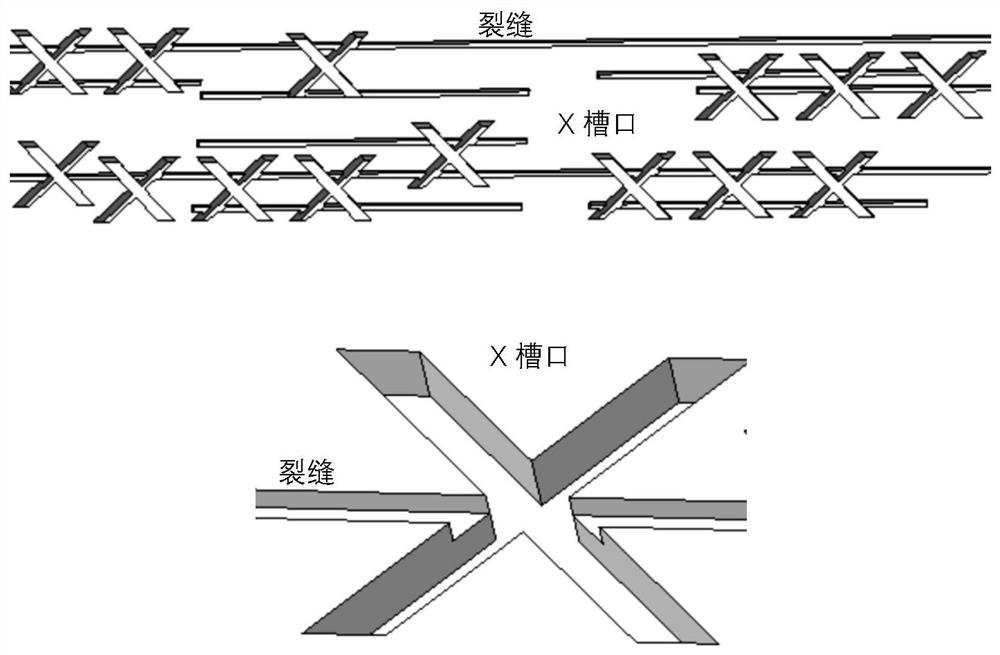

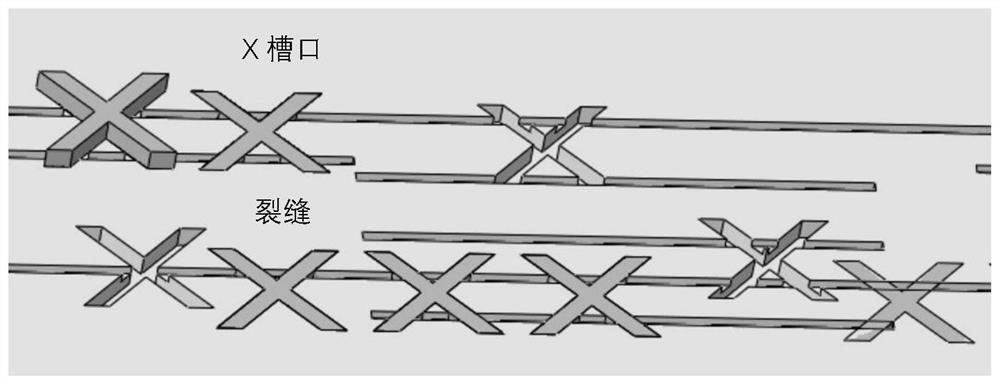

[0033] The fiber concrete used in this embodiment is chopped ultra-high molecular weight polyethylene fiber concrete, its tensile strength is 5MPa, the strain corresponding to the maximum tensile strength is 6%, and its compressive strength is 30MPa. For example and not limitation, the grooves in this embodiment are treated with X-shaped grooves before the cracks are repaired, and the size of the X-shaped grooves is determined according to the width of the cracks. Appropriate values are arranged along the length of the cracks, such as figure 1 shown. After the cracks in this embodiment are strengthened by the X-shaped caulking formed by fiber concrete pouring, it is as follows: figure 2 shown.

[0034] In this implementation, the method of repairing cracks in wooden structures with fiber reinforced concrete is as follows:

[0035] (1) Marking of cracks in the wooden structure body;

[0036] (2) Multiple X-shaped grooves are opened along the length of the crack. The thick...

Embodiment 2

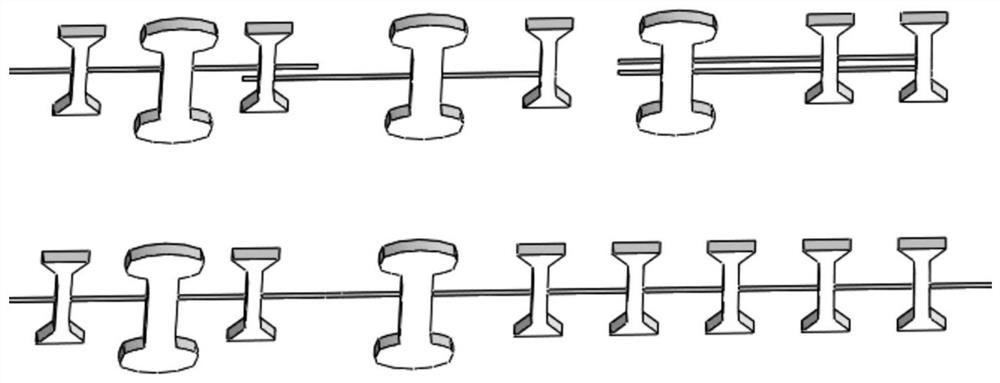

[0043] The fiber concrete used in this embodiment is polyvinyl alcohol (PVA) fiber cement-based composite material, its tensile strength is 3MPa, the strain corresponding to the maximum tensile strength is 3%, and its compressive strength is 35MPa. For example and not limitation, the grooves in this embodiment are treated with dumbbell-shaped grooves before the cracks are repaired. The size of the dumbbell-shaped grooves is determined according to the width of the cracks and arranged along the length of the cracks, such as image 3 shown. In this embodiment, the cracks are reinforced by the dumbbell-shaped caulking formed by fiber concrete pouring. Figure 4 shown.

[0044] In this implementation, the method of repairing cracks in wooden structures with fiber reinforced concrete is as follows:

[0045] (1) Marking of cracks in the wooden structure body;

[0046] (2) Open a dumbbell-shaped groove along the length of the crack, the end of the groove is excessively arc-shaped,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com