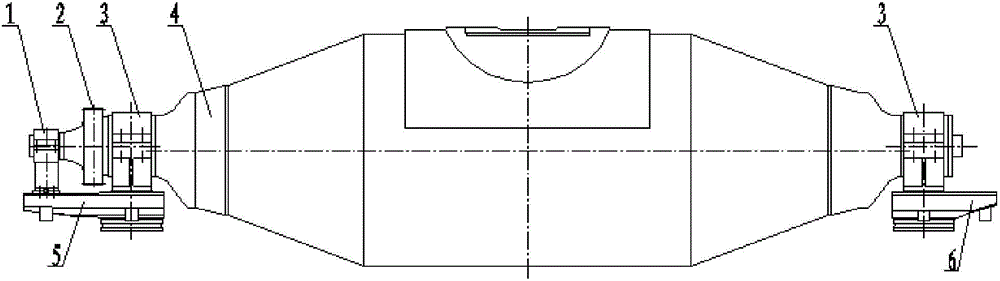

Stepless Adjustment Device for Auxiliary Bearing of Torpedo Type Mixed-rail Vehicle

An auxiliary bearing and stepless adjustment technology, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of broken bolts, loosening, difficult adjustment of gasket groups, etc., and achieve the effect of convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

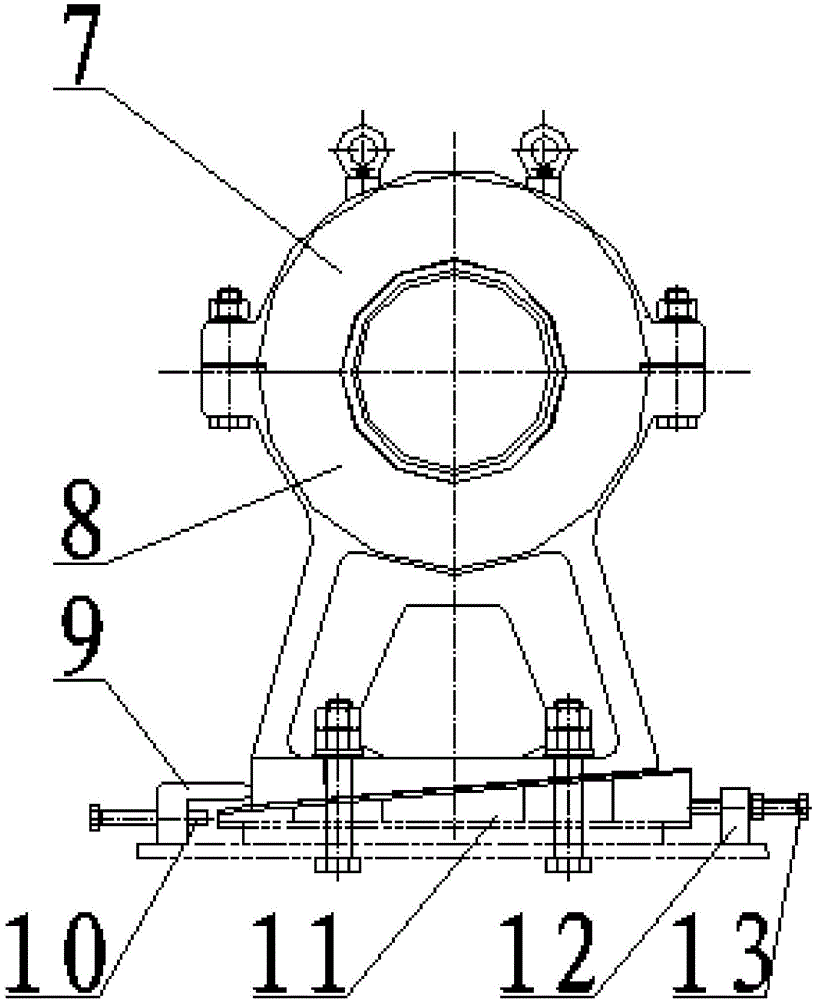

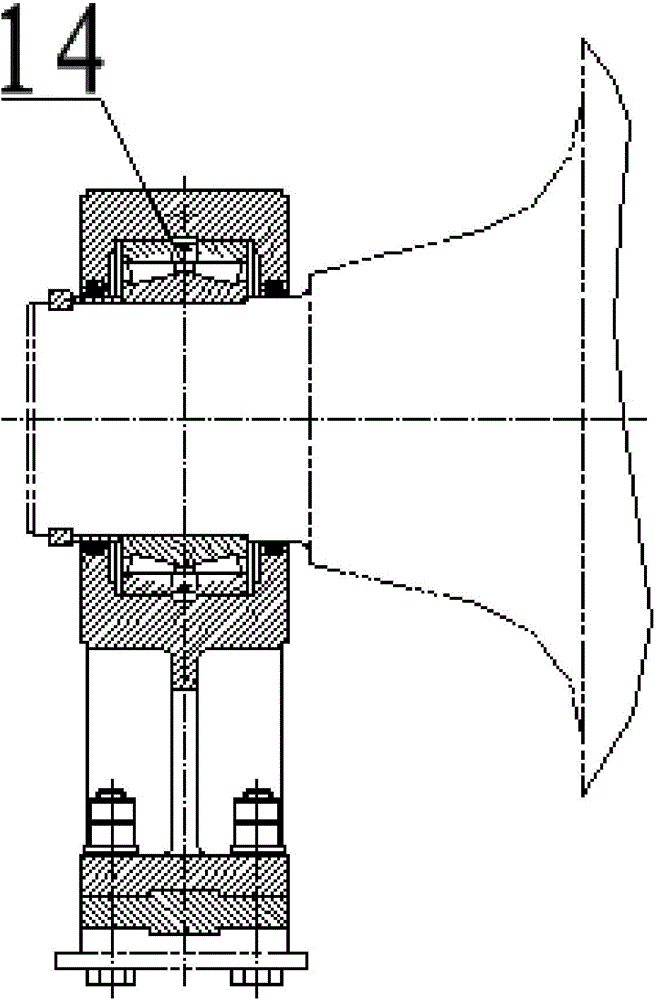

[0020] The present invention will be further described below in conjunction with the drawings and embodiments.

[0021] The torpedo type hybrid vehicle auxiliary bearing stepless adjustment device includes auxiliary bearing seat 8, drive side stand 5, stopper A9, top wire A10, wedge pad 11, stopper B12 and top wire B13. The auxiliary bearing seat 8 is installed in the drive On the side frame 5, the auxiliary bearing is installed in the auxiliary bearing seat 8 and fixed by the upper bearing cover 7. The wedge angle α of the wedge pad 11 is 3°~8°, and the width of the wedge pad 11 is the same as the bottom of the auxiliary bearing seat 8. , The length is the same as the length of the bottom of the auxiliary bearing seat 8 or exceeds the length of the bottom of the auxiliary bearing seat 8 by 10%. Between the inclined plane and the horizontal plane of the wedge-shaped washer 11 is provided a boss with the same length as the inclined plane and the horizontal plane. Two oblong holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com