Internal-swelling type stator hoisting special purpose tools

A technology of special tools and lifting tools, which is applied in the direction of load hanging components, manufacturing motor generators, electrical components, etc., and can solve problems such as increasing costs and labor intensity, difficulty in controlling press-fitting quality, and increasing the difficulty of stator alignment. , to achieve the effect of reducing tool placement space, less clamping times, mechanism compatibility and good replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

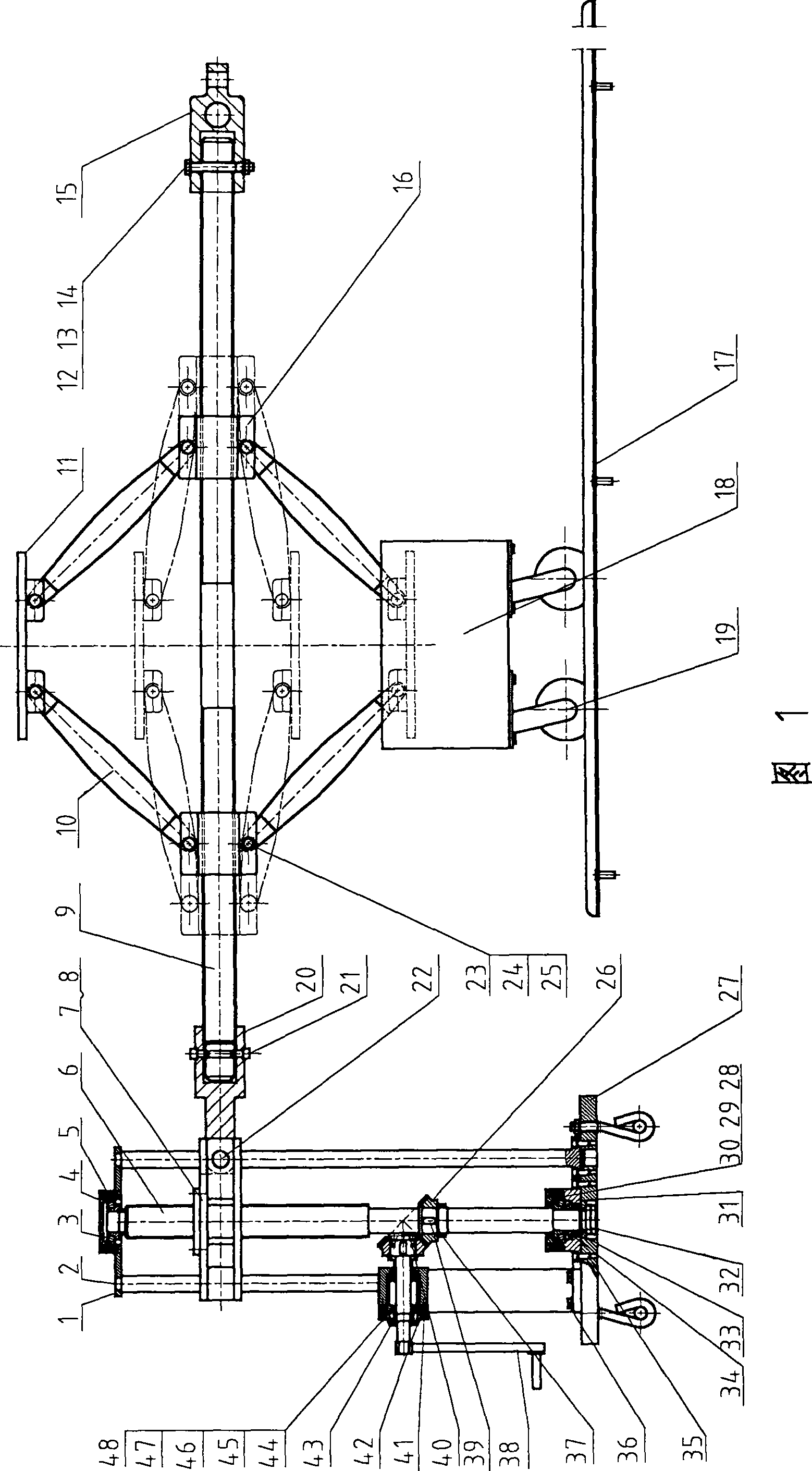

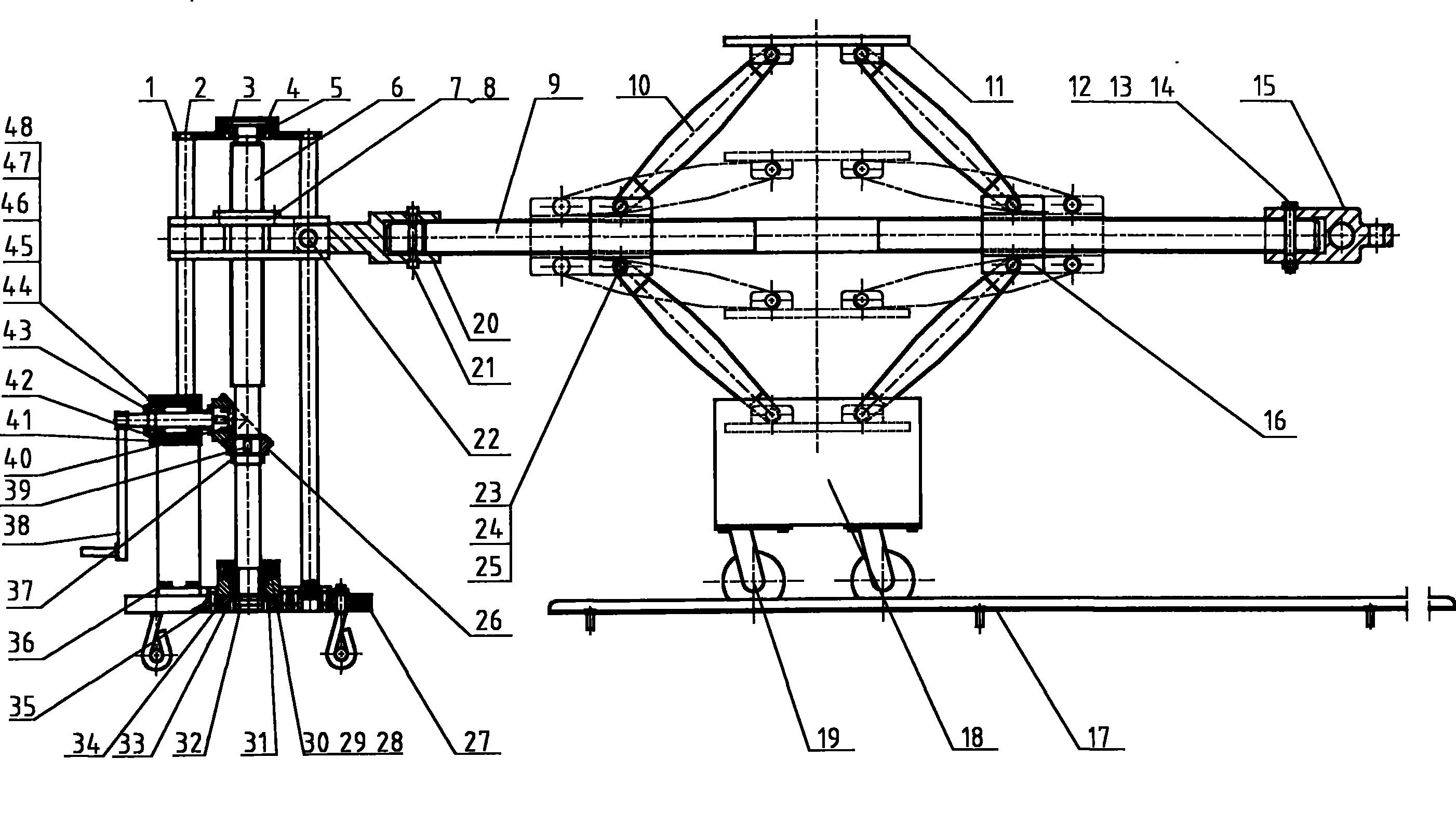

[0020] As shown in Figure 1, the present invention comprises lifting workbench, inner expansion type hoisting tool and pulley cart. Wherein the elevating workbench includes four guide columns 2 to connect the upper frame plate 1 and the lower base plate 27, the upper end of the screw rod 6 is provided with a spacer and a tapered roller bearing 3, and the stuffy cover 4 is fastened on the upper frame plate 1 by screws 5. The lower end of the screw rod 6 is equipped with a tapered roller bearing 3 and a thrust bearing 33, separated by a spacer 34 in the middle. The sealing transparent cover 28 is fastened on the bearing seat 31 with screws 30 . The rotary motion of the screw rod 6 is realized by a pair of meshing bevel gears 26, one gear is locked on the screw rod 6 by a round nut 37, and the other gear is installed on the gear with two spacers 45, 46 and a pair of tapered roller bearings 44. On the shaft 48, the two ends are spliced tightly by the round nut 43 and the block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com