High temperature and high pressure foam liquid dynamic fluid loss detection system and its detection method

A detection system, high temperature and high pressure technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that strong stirring cannot be realized, gas-liquid separation cannot be realized, etc., and achieve high creativity, scientific and reasonable design, and accurate detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

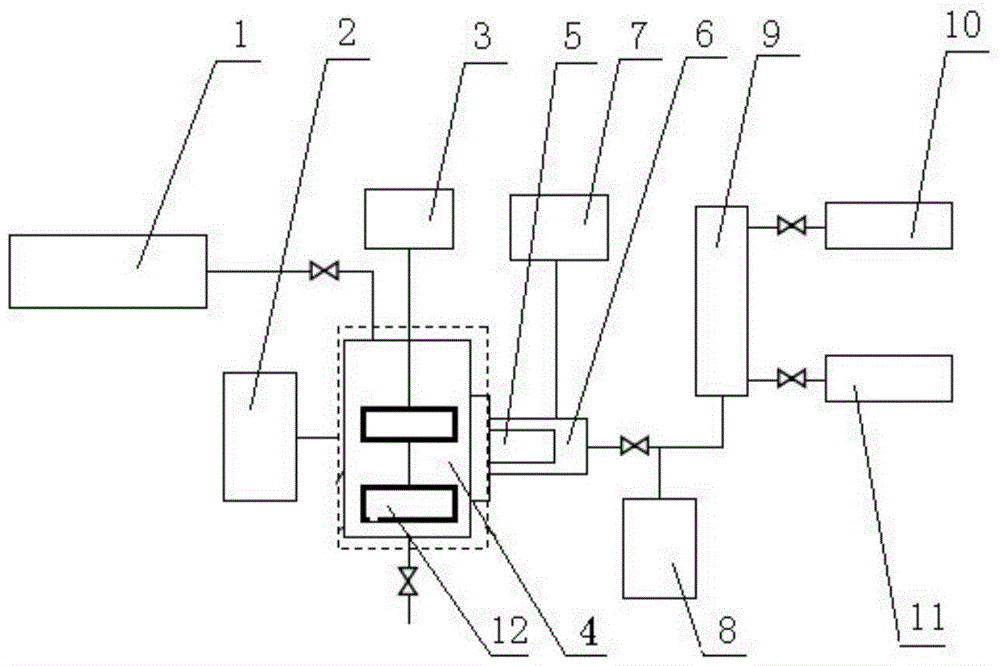

[0027] A dynamic fluid loss detection system for high-temperature and high-pressure foam liquid, including a fluid loss system, a core holder 6, a back pressure valve 8, and a clamper confining pressurization device 7. The fluid loss system is connected to the core holder. A rock core 5 is coaxially embedded in the holder, a return pressure valve is connected to the outlet end of the rock core holder, and a holder confining pressure increasing device is also connected to the rock core holder.

[0028] The innovation point of the present invention is:

[0029] 1. The filter loss system includes a filter loss chamber 4 and a paddle agitator 12, a paddle agitator is coaxially installed in the filter los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com