Computing method of energy saving rate of energy-saving stove based on dry burning prevention

A calculation method and energy-saving rate technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of increasing waste gas emissions, cumbersome operations, and low market penetration rate, and achieve the elimination of doubts, easy implementation, and popular calculation methods understandable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

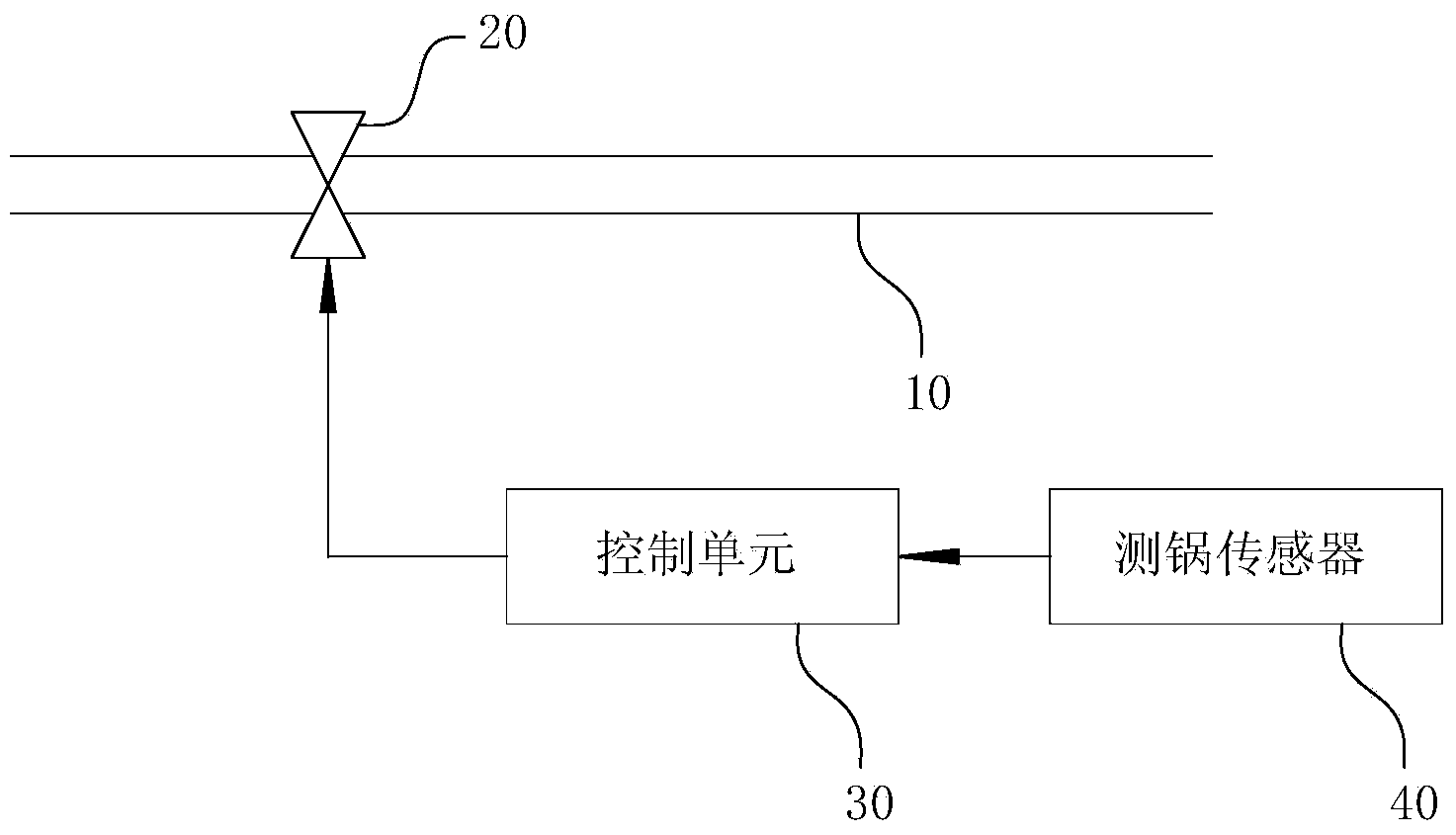

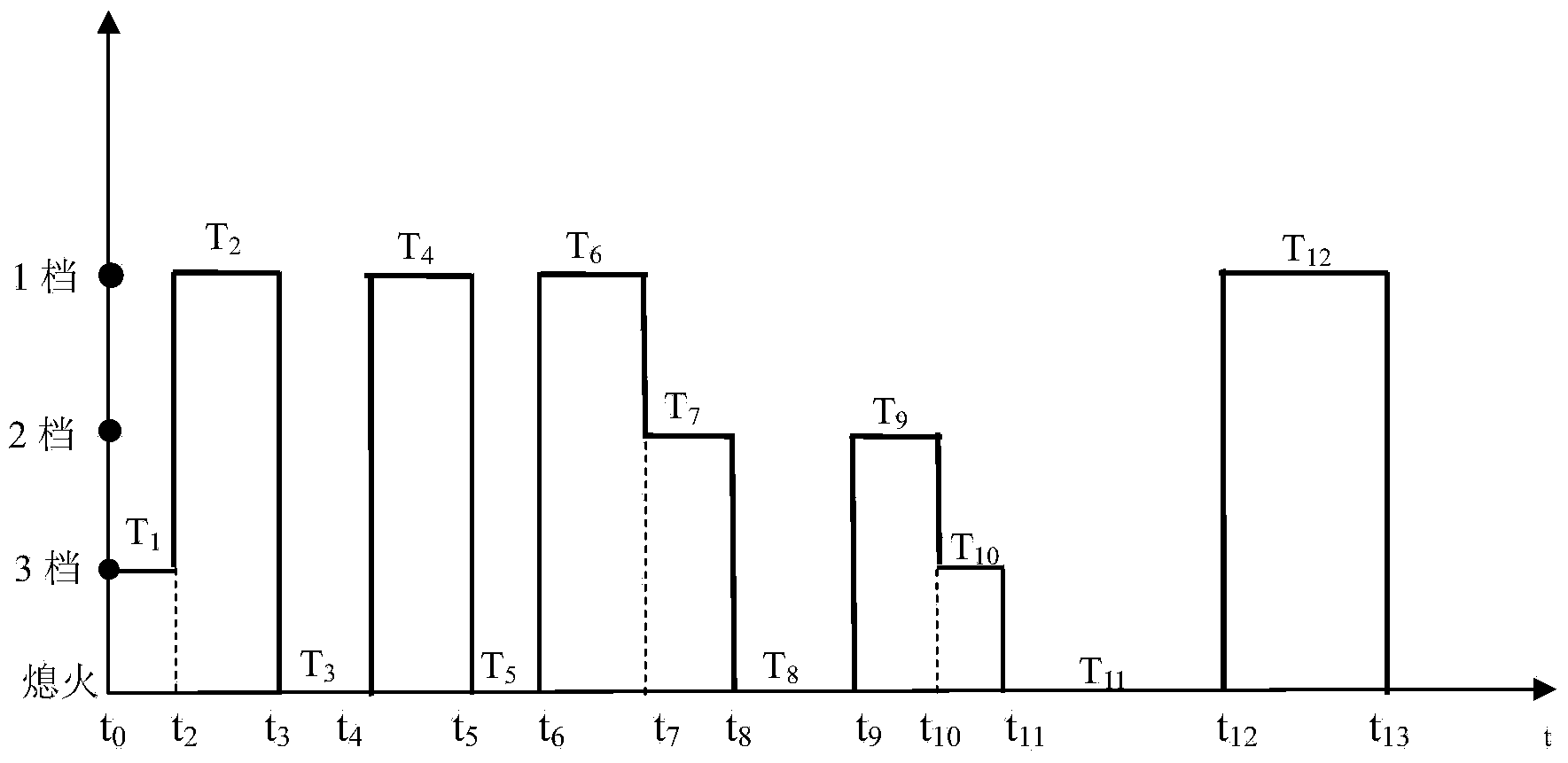

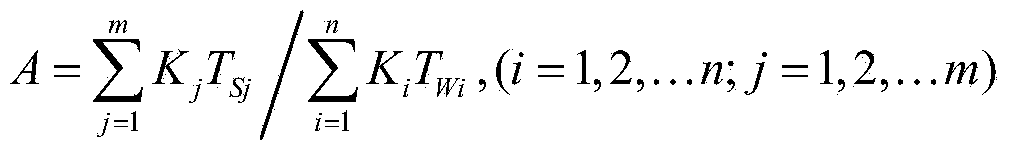

[0032] For ease of understanding, combined here Figure 1~2 Specific examples of the present invention are given.

[0033] The specific embodiment of the present invention is illustrated with the following three-gear valve as its explanation example:

[0034] 1), calculate the calibration coefficient K

[0035] Divide the target stove into three grades according to the size of the fuel flow, that is, the size of the flow corresponds to the opening and closing of the valve, and is divided into three grades: large, medium and small; the gear corresponding to the maximum flow is grade 1, which is recorded as Q 1 , when the middle flow rate corresponds to the second gear, denoted as Q 2 , the gear corresponding to the minimum flow is 3rd gear, denoted as Q 3 ; Then the calibration coefficient K corresponding to the 3 stalls is obtained as follows:

[0036] 1 gear, flow value Q 1 , let the check coefficient K in this case 1 = 1;

[0037] 2nd gear, flow value Q 2 , the check...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com