A kind of anti-cracking block manufacturing equipment

A manufacturing equipment and anti-cracking technology, applied in manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve problems such as height errors, and achieve the effect of improving production efficiency, reducing labor costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

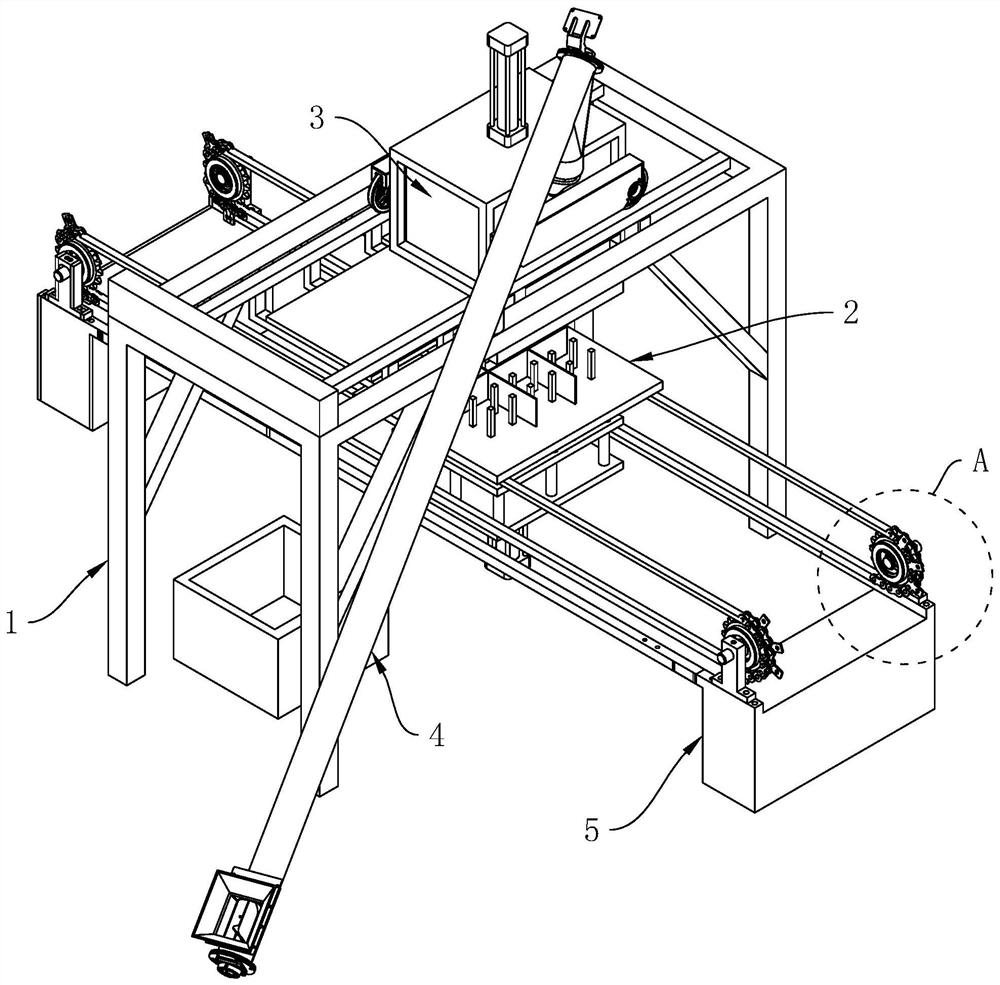

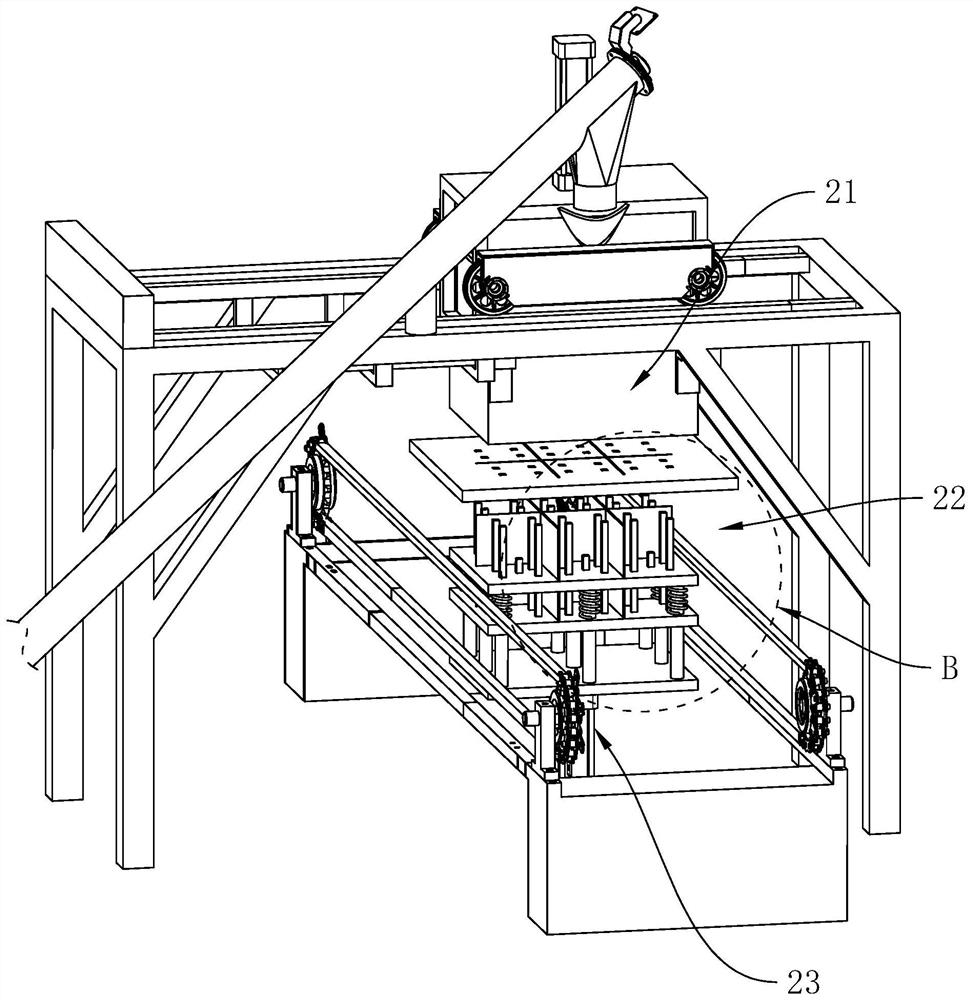

[0042] The embodiment of the present application discloses an anti-cracking block manufacturing equipment. refer to figure 1 , the anti-cracking block manufacturing equipment includes a frame 1, a mold assembly 2, a compaction assembly 3, a screw feeder 4, and a conveyor 5; wherein, the frame 1 is installed on the ground for supporting and carrying, and the mold assembly 2 is set at the bottom of the frame 1 for block forming, the compaction assembly 3 is set at the upper end of the frame 1 for compacting raw materials in the mold box 21, and the screw feeder 4 is set at the bottom of the frame 1 One side thereof is used for automatically supplying raw materials, and the conveyor 5 is arranged at the lower end of the frame 1 for transferring compacted blocks.

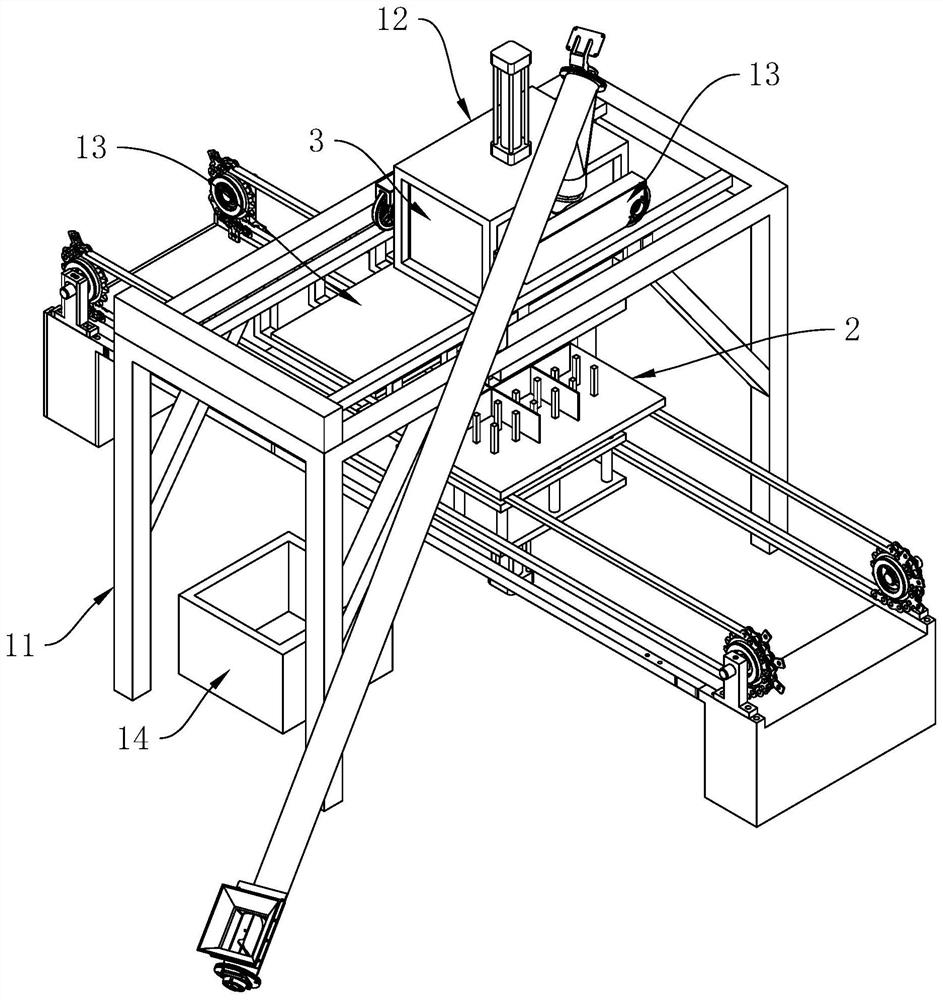

[0043] refer to figure 1 and figure 2 , the frame 1 includes a base 11, a mounting seat 12, a material blocking plate 13 and a recovery box 14, the base 11 is installed on the ground, the mounting seat 12 is slidabl...

Embodiment 2

[0054] refer to Figure 8 , the difference between this embodiment and embodiment 1 is that the mold assembly 2 and the conveyor 5 are provided with several pieces, the conveying direction of each piece of conveyor 5 is perpendicular to the length direction of the base 11, and the conveyor 5 The conveying direction and the moving direction of the mounting seat 12 are perpendicular to each other. There are several pieces of baffle plate 13, and each mold assembly 2 is arranged alternately with each piece of material baffle plate 13, and each mold assembly 2 is arranged along the conveyor 5. Arrangement in conveying direction.

[0055] Compared with Embodiment 1, the installation base 12 in Embodiment 2 can produce multiple batches of blocks in one round trip, which further improves the production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com