Amorphous alloy dry-type transformer body overturn device

A technology of dry-type transformers and amorphous alloys, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as low safety factor, low efficiency, and failure to ensure assembly reliability, and achieve great economic benefits and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

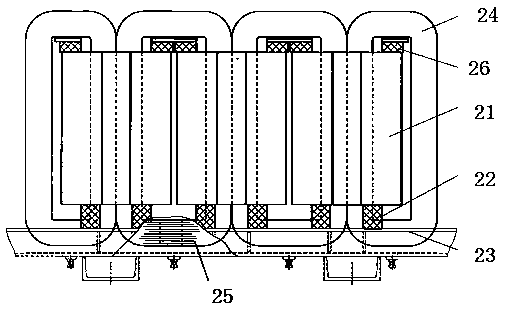

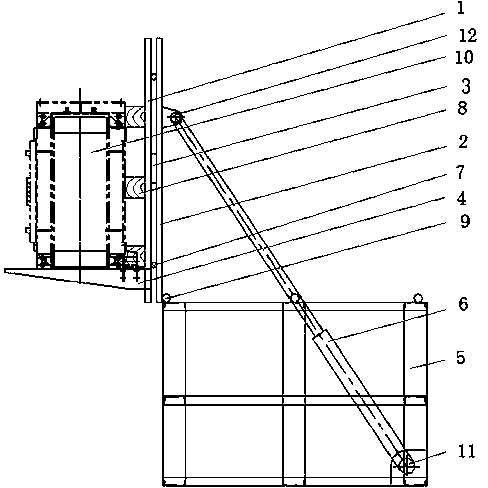

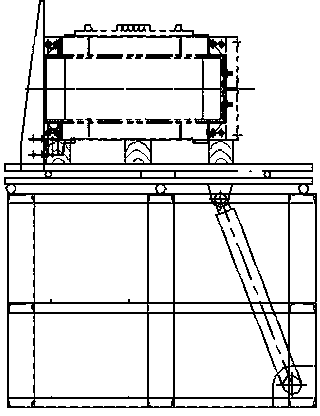

[0016] An amorphous alloy dry-type transformer body turning device, see figure 2 , the device includes an upper tray 1, a lower tray 2, a tray rotating shaft 3, a body support 4, a turning support 5 and a hydraulic device 6, the tray rotating shaft is arranged at the center of the lower tray, and the upper tray rotates 360 degrees around the tray rotating shaft Set on the tray rotating shaft, and the upper tray is set on the lower tray through the rotating bead 7; the rotating beads are cylindrical cone structure and evenly distributed on the circumference with the tray rotating shaft as the center, and play the role of supporting and rotating the upper tray. The upper tray is provided with a sleeper 8 for fixing the transformer body 10, and a body support 4 for supporting the transformer body is provided at the edge of the upper tray, and the body support can be arranged at the front and back symmetrical positions of the transformer body, that is, It is located on the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com