Manufacturing method for micro-aperture aluminum pipes

A manufacturing method and technology of aluminum tubes, which are applied to cutting tools for planer/slotting machines, manufacturing tools, routers, etc., can solve problems such as the inability to remove small bumps on the inner wall, small diameter of the inner wall, and inner walls with tolerances, etc., and achieve high speed Fast, elastic, consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

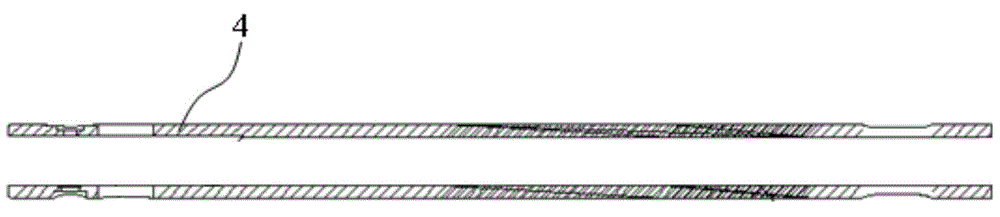

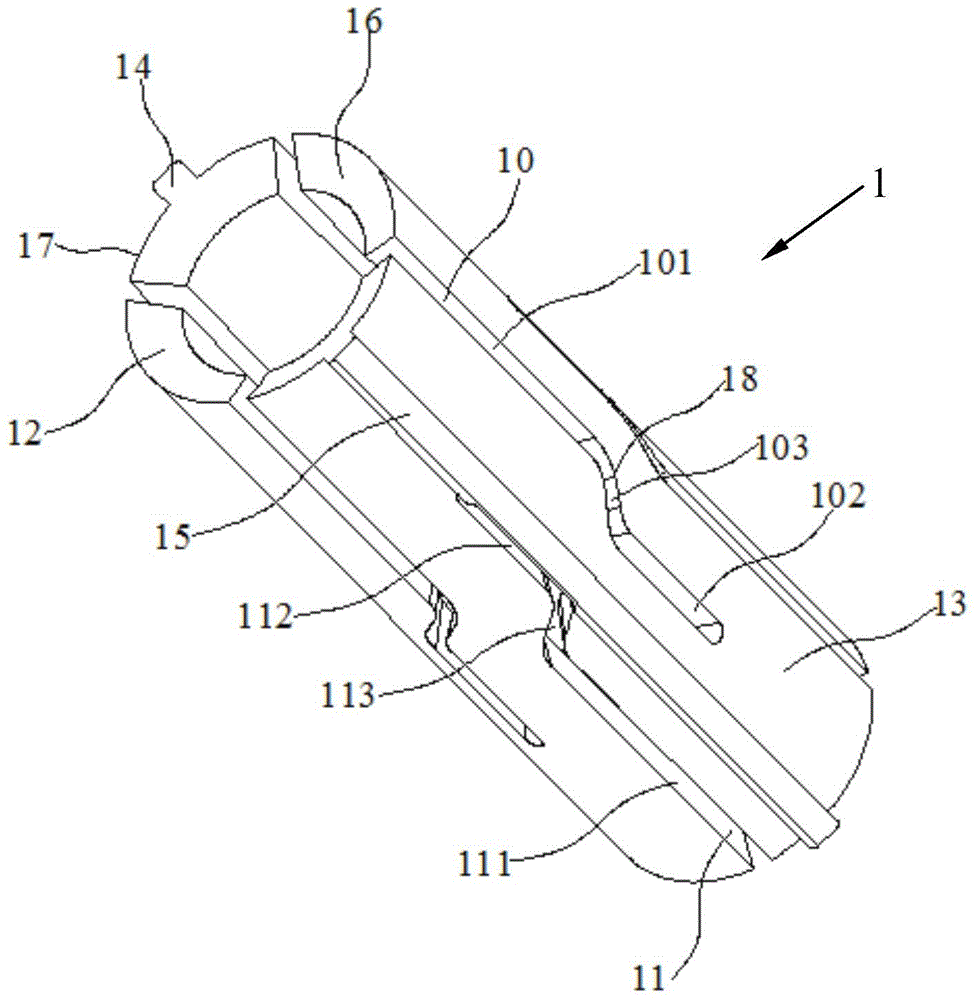

[0026] Embodiment: a manufacturing method of a micro-diameter aluminum tube, the manufacturing method is based on a circular insertion knife 1, a pressing mechanism 2, a push rod 3 and a micro-diameter aluminum tube 4;

[0027] The circular slot 1 is provided with several first wire slots 10 and several second wire slots 11 in parallel along its axial direction, and the first wire slots 10 extend from one end surface of the round slot 1 to the circular The middle part of the insertion knife 1 forms several first elastic blades 12, and the second wire passage groove 9 extends from the other end face of the circular insertion knife 1 to the middle part of the circular insertion knife 1 to form several second elastic blades 13. The slot 10 and the second wire slot 11 partially overlap along the circumferential direction. The first wire slot 10 is composed of a first front slot 101, a first rear slot 102 and a first bending slot 103. The first rear slot The wire slot 102 is locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com