A side turning device for bagged feed conveying

A bag packaging and feed technology, which is applied in the field of bag packaging feed conveying side-turning device, can solve the problems of irregular, random and disordered posture, and bag packaging feed is not in place, so as to achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

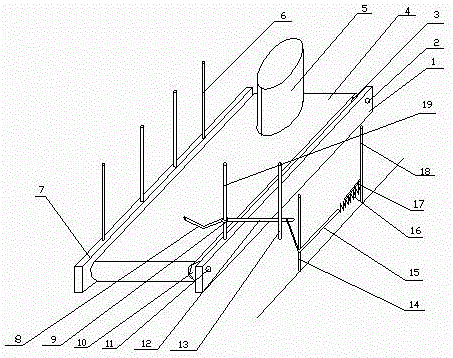

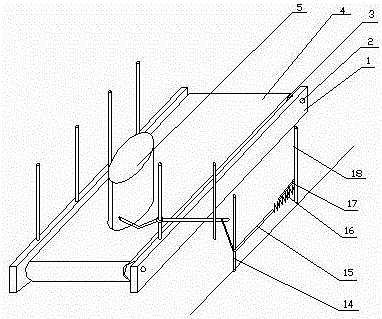

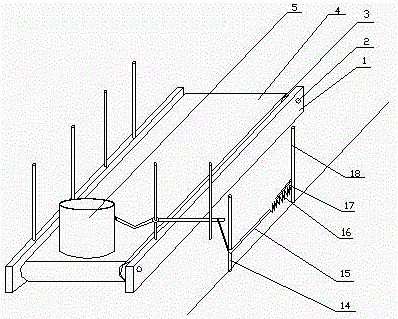

[0024] as attached Figure 1~5 Shown: a side-turning device for conveying bag-packed feed, which includes: a conveying part, a side-turning part, and a decoupling part.

[0025] The conveying part includes: the first beam 1, the first roller shaft 2, the first roller 3, the conveyor belt 4, the bagged feed 5, the railing 6, the second beam 7, the second roller 10, the second roller shaft 11, The first roller shaft 2 is installed on the right end of the first beam 1, the first roller 3 is installed on the first roller shaft 2, the right end of the conveyor belt 4 is wound on the first roller 3, the bagged feed 5 is located above the conveyor belt 4, and the railing 6 is installed on the second beam 7, one end of the first roller shaft 2 is movably installed on the right end of the second beam 7, the second roller 10 is installed on the second roller shaft 11, and one end of the second roller shaft 11 is movably installed on the first The left end of crossbeam 1, the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com