Lifting ladder for indoor building construction

A technology for building construction and elevators, which is applied in the direction of hoisting devices, safety devices for lifting equipment, etc., and can solve problems such as unusable elevators, low stability of elevators, and unsafe construction personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

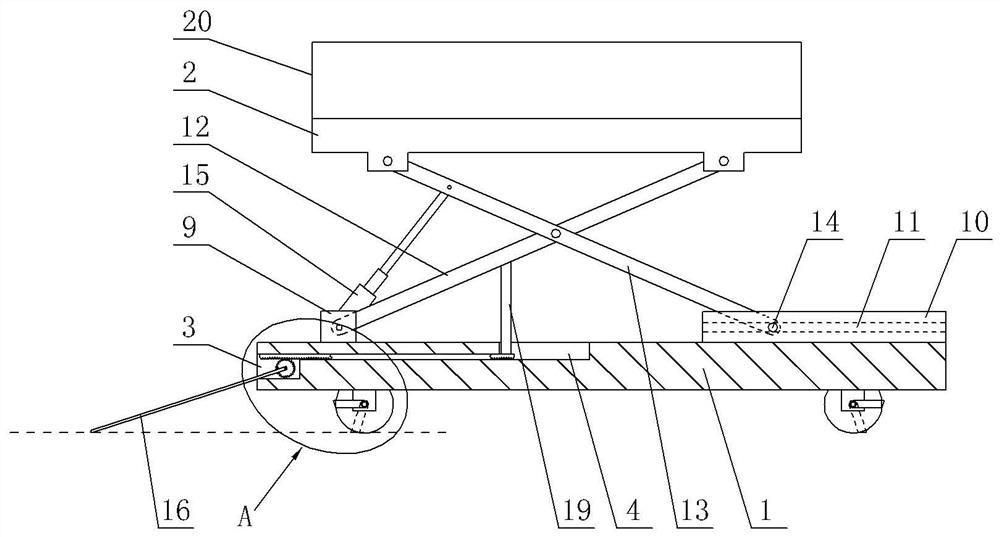

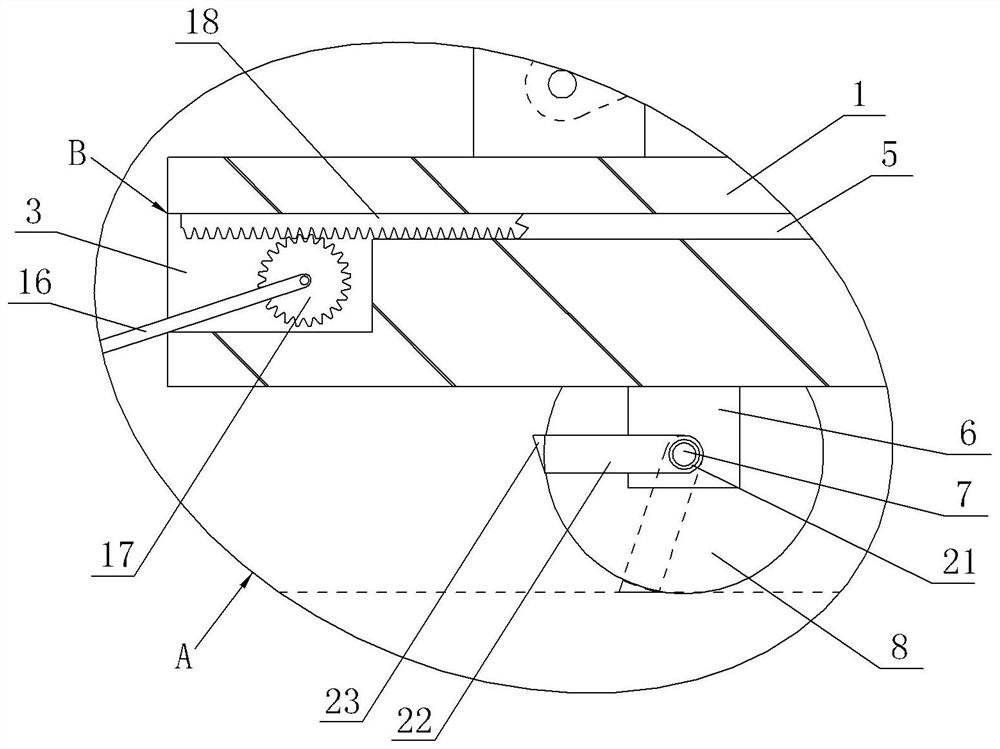

[0025] Embodiment one is basically as attached figure 1 , 2 Shown: as figure 1 A lift for indoor construction is shown, comprising a base 1, a support plate 2 and a lifting and stabilizing mechanism. The lifting and stabilizing mechanism includes a lifting unit and a stabilizing unit; A second groove 4 is formed on the surface, a slideway 5 is formed in the base 1 , and the first groove 3 communicates with the second groove 4 through the slideway 5 .

[0026] The bottom of the base 1 is provided with a traveling mechanism, and the traveling mechanism includes two walking units, such as figure 2 As shown, each walking unit includes a support block 6, a support shaft 7 and two rollers 8, the support block 6 is welded to the lower surface of the base 1, a through hole is provided on the support block 6, and the support shaft 7 and the side wall of the through hole Rotationally connected, the two rollers 8 are respectively coaxially fixedly assembled on the front and rear ends...

Embodiment 2

[0038] On the basis of Example 1, as figure 2 As shown, at least one locking mechanism is also included, that is, there can be one locking mechanism, and now the locking mechanism is located at the right end of the base 1; the number of locking mechanisms in this embodiment is two, and each locking mechanism includes a sleeve The barrel 21 and at least one locking unit. In this embodiment, each locking mechanism includes a locking unit, and the locking unit is located in front of the support block 6 .

[0039] Specifically, each locking unit includes a rotating block 22 and a locking block 23, the rotating block 22 and the locking block 23 are welded, and the top view of the rotating block 22 and the locking block 23 is "L" shaped; the sleeve 21 passes through The outer wall of the support block 6 and the sleeve 21 is welded with the support block 6, the support shaft 7 is rotatably connected with the sleeve 21, the length of the support shaft 7 is greater than the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com