Holder unit and scoring device

A retainer and scoring wheel technology, applied in signal devices, glass cutting devices, audible signal devices, etc., can solve the problems of easily damaged glass substrates, and achieve the effect of improving the strength of the end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

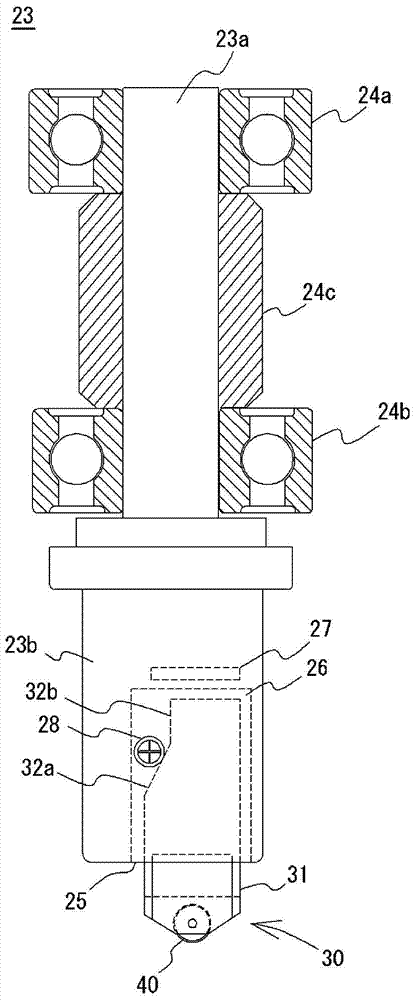

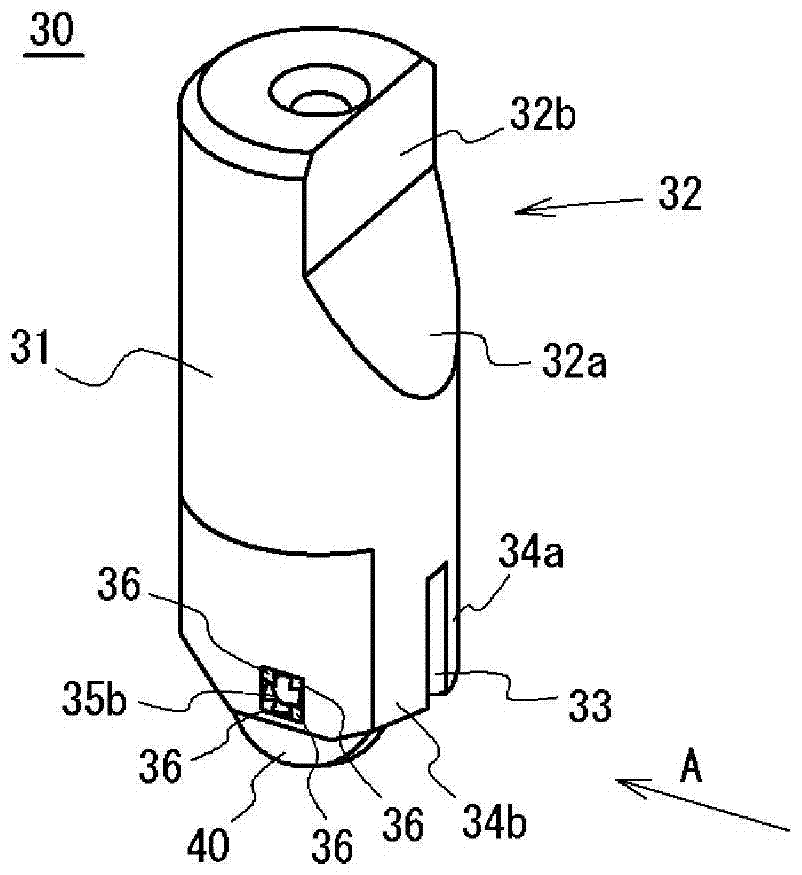

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the embodiment shown below is only an example for embodying the technical idea of the present invention, and it is not intended that the present invention is specific to the embodiment. The present invention can also be applied to other embodiments included in the scope of the patent application.

[0036] [Embodiment 1]

[0037] At figure 1 A schematic diagram showing a scribing apparatus 10 according to Embodiment 1 is shown. The scribing apparatus 10 includes a mobile station 11 . Further, the moving table 11 is screwed with the ball screw 13, and the ball screw 13 is rotated by the drive of the motor 14, and can move in the y-axis direction along the pair of guide rails 12a and 12b.

[0038] On the upper surface of the moving table 11, a motor 15 is provided. The motor 15 rotates the upper stage 16 in the xy plane and is positioned at a predetermined an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com