Manufacturing method for non-water humidifying reel of air-conditioner and special apparatus thereof

A manufacturing method and air-conditioning technology, which is applied in the direction of lighting and heating equipment, heating methods, air-conditioning systems, etc., can solve the problems of reducing the humidification effect of the runner, affecting the moisture absorption effect, polluting the air, etc., and achieves excellent moisture absorption performance, end surface flatness and Good friction resistance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

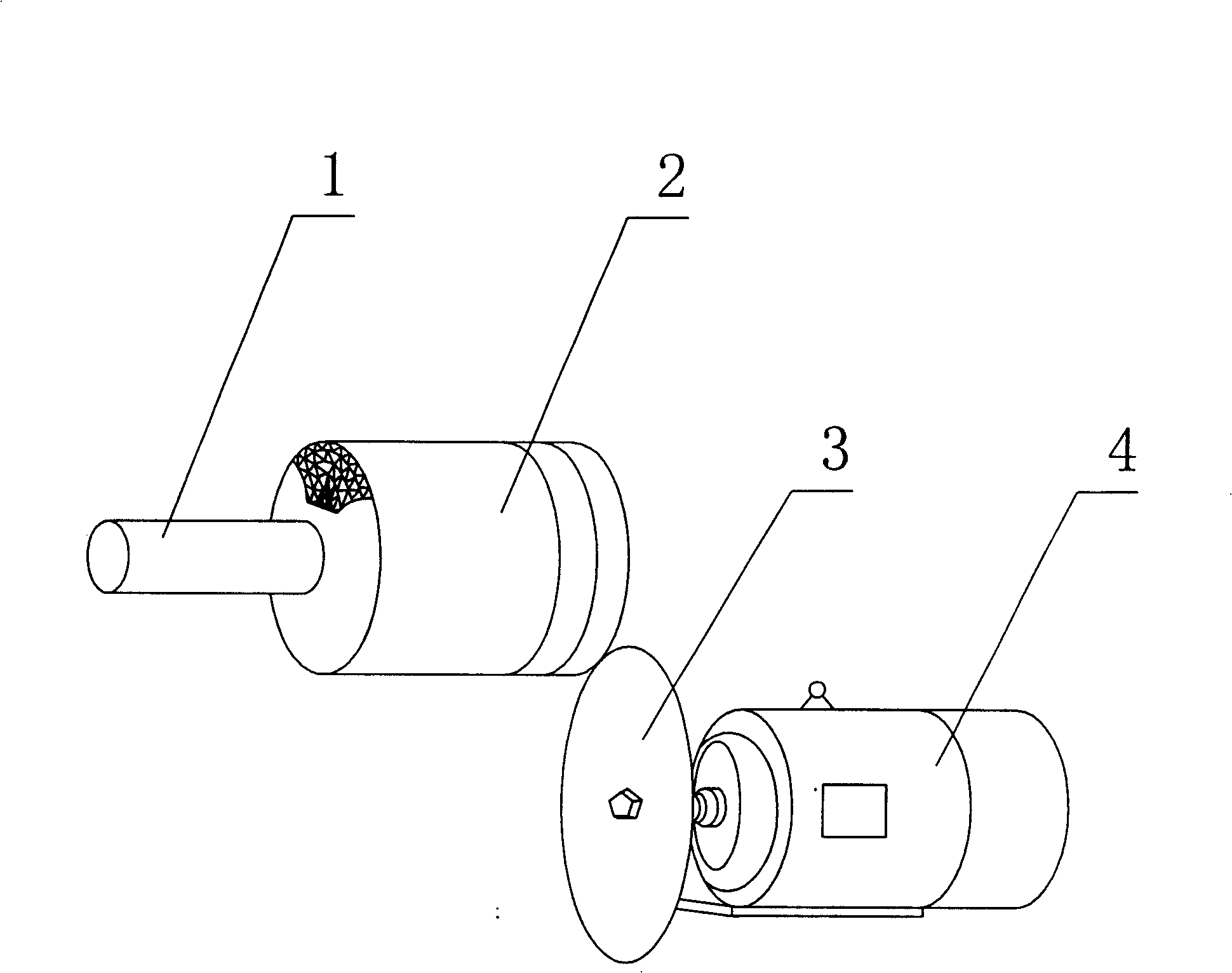

[0015] As shown in the figure, after corrugated by inorganic fiber paper, a cylindrical honeycomb matrix is made, the diameter is usually 200-300mm, and it is immersed in water glass solution with a concentration of 25-33% for 1-1.5 hours. Take out, blow out the liquid, air-dry to about 60-70% dryness, and then immerse it in an inorganic acid or inorganic salt solution with a solution concentration of 15-25% for 2-4 hours. The inorganic acid is selected from sulfuric acid, and the inorganic acid salt is selected from sulfuric acid. Salt, other inorganic acid or inorganic acid salt solution can also be used to generate silica gel, which is washed and dried and cut into a thickness of 20-30mm with special equipment. Then, 5-10% of sodium fluorosilicate curing agent is added with water glass solution with a concentration of 10-30%, and the cut end face is coated and hardened. The end face of the anhydrous humidifying wheel for air conditioner can obtain good end face strength a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com