marking wheel

A scribing wheel and shape wheel technology, applied in glass manufacturing equipment, metal processing, fine working devices, etc., to achieve the effect of improving the strength of the end face, good grip, and improving the strength of the end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the embodiments shown below represent an example of a scribing wheel for realizing the technical idea of the present invention, and are not intended to limit the present invention to this scribing wheel, and can be similarly applied to those included in the scope of the claims. Other embodiments of the marking wheel. In addition, in the drawings shown below, in order to recognize each structure easily, the scale is suitably changed for each structure part, and it is not necessarily shown according to an actual size or an angle.

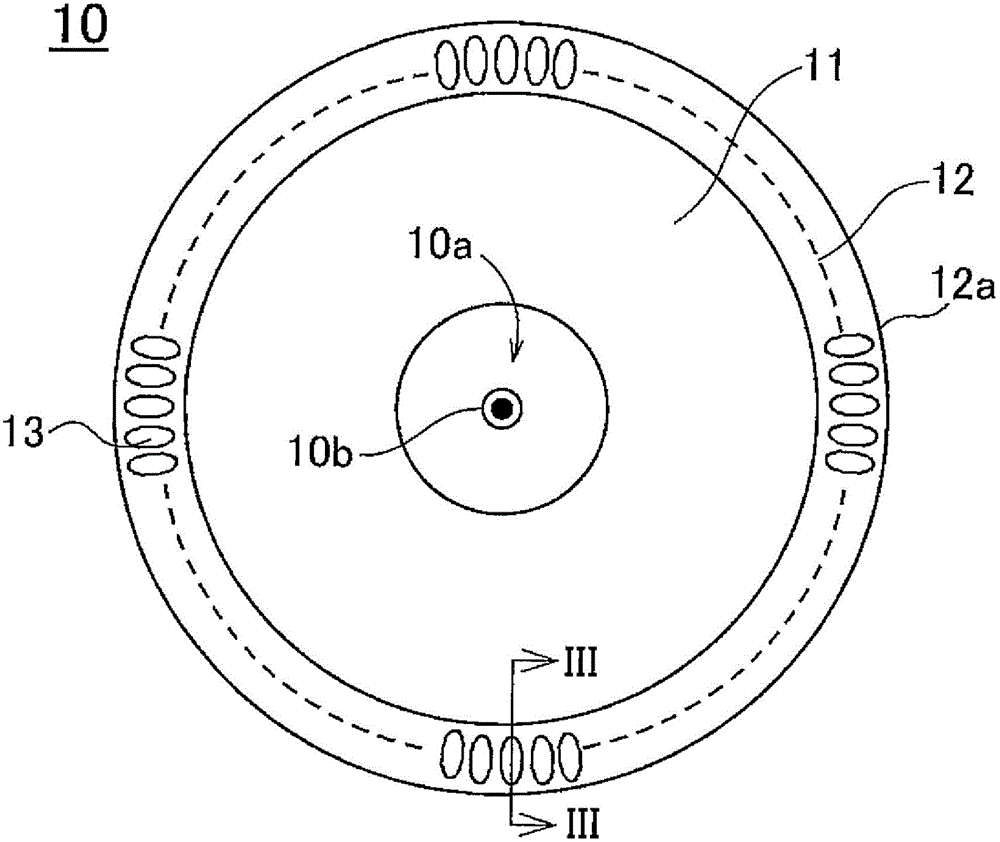

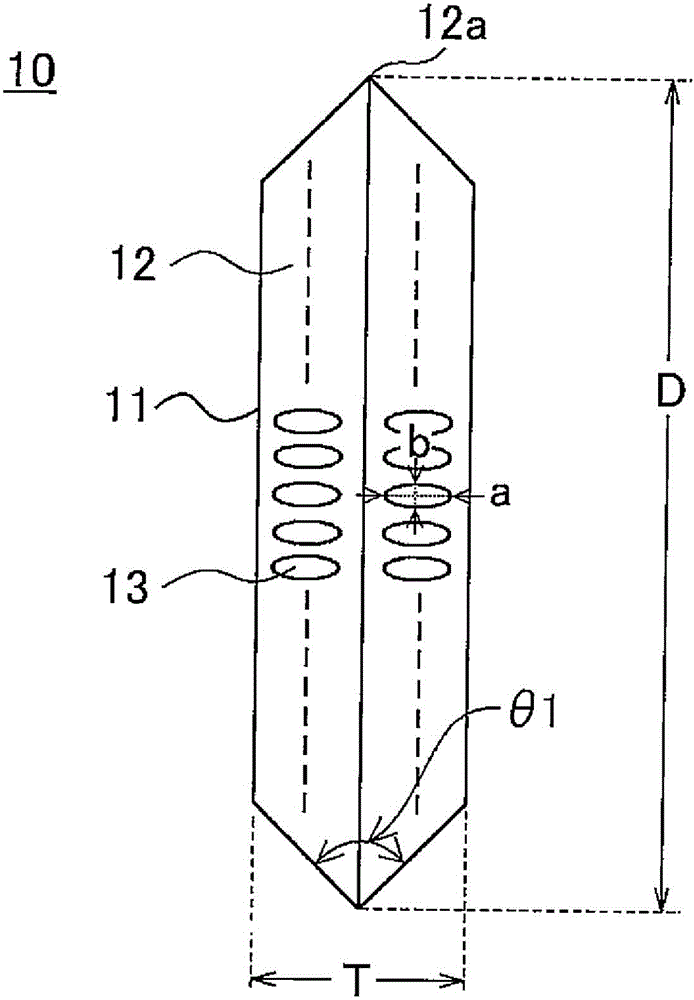

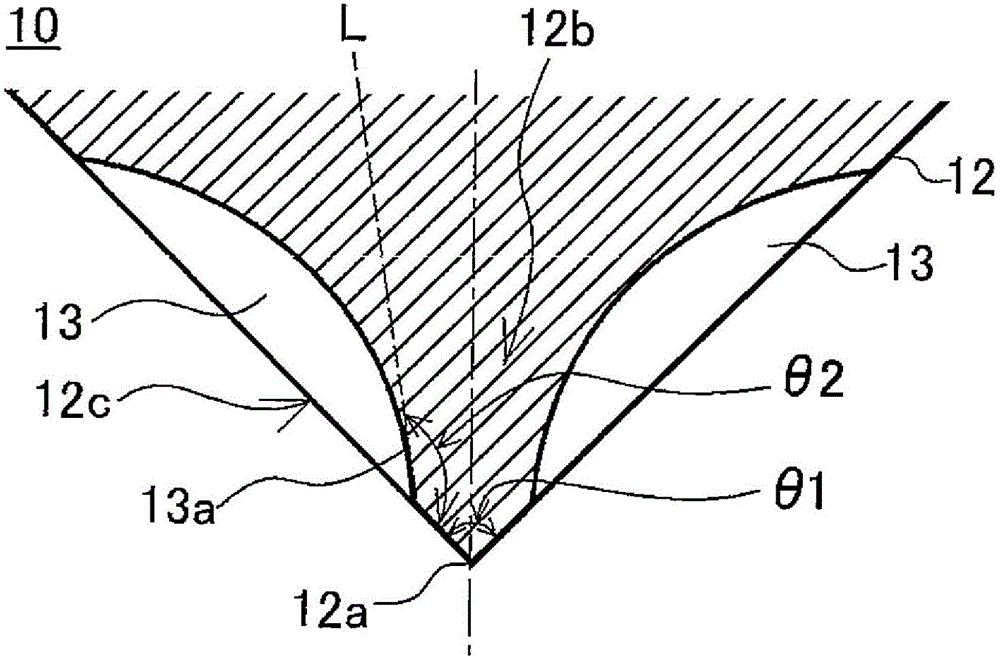

[0062] First, refer to Figure 1 ~ Figure 3 The scribing wheel of the embodiment will be described. in addition, figure 1 It is a side view of the scribing wheel of embodiment. figure 2 yes figure 1 front view of a scribing wheel. image 3 is along figure 1 An enlarged sectional view of line III-III.

[0063] Such as Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com