Breaking method and breaking device

A fracture and substrate technology, applied in glass cutting devices, stone processing equipment, glass manufacturing equipment, etc., can solve problems such as long working hours, complicated operations, and difficult implementation of production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, methods and steps of the breaking method and breaking device proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , structure, feature and effect thereof, detailed description is as follows.

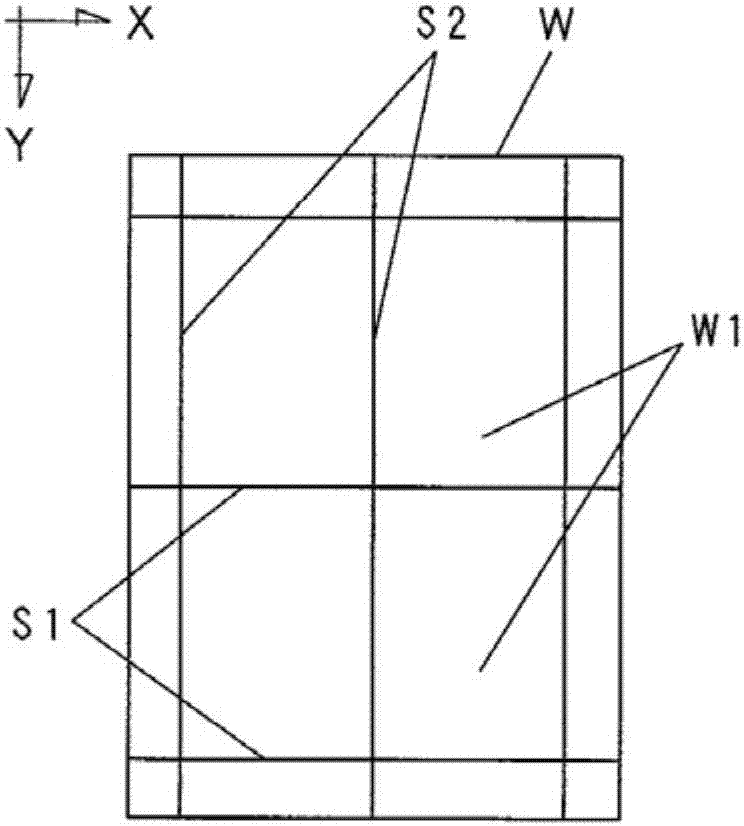

[0037] The substrate W to be broken in the present invention is, for example, a thin plate glass with a thickness of 0.1 to 0.5 mm used for a cover glass of a panel for a liquid crystal display, such as figure 1 As shown, a plurality of, in this embodiment, four unit products W1 are cut out by dividing from one mother substrate W along grid-like planned scribing lines S1 and S2 perpendicular to each other in the X-Y direction.

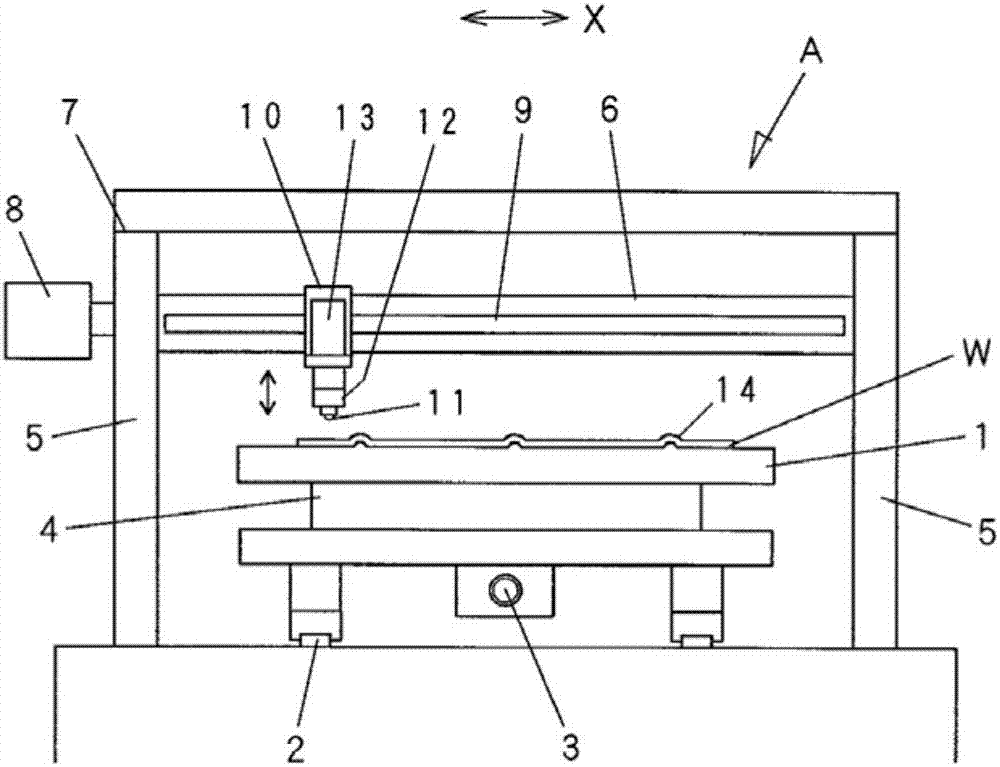

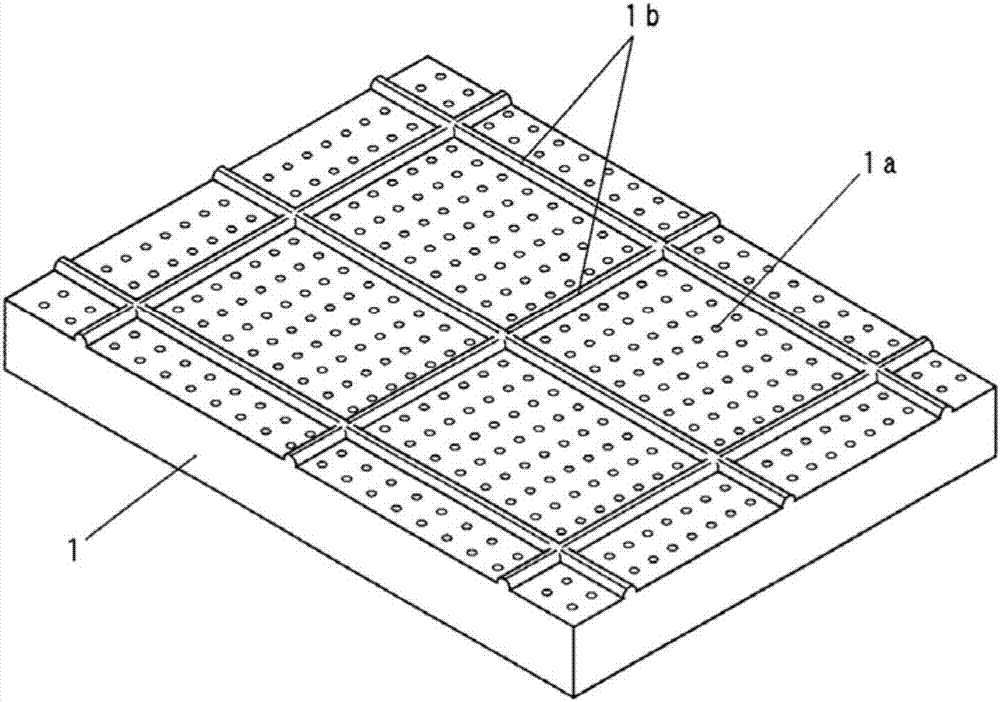

[0038] figure 2 It shows the cleavage apparatus A of this invention, and it is provided with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com