Method for manufacturing drive disc of electromagnetic fan clutch, mould and manufactured drive disc

An electromagnetic fan and transmission disc technology, which is applied in the transmission disc field, can solve the problems of large processing volume and complex transmission disc manufacturing, and achieve the effects of improving the yield, making up for the adverse effects and reducing the weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

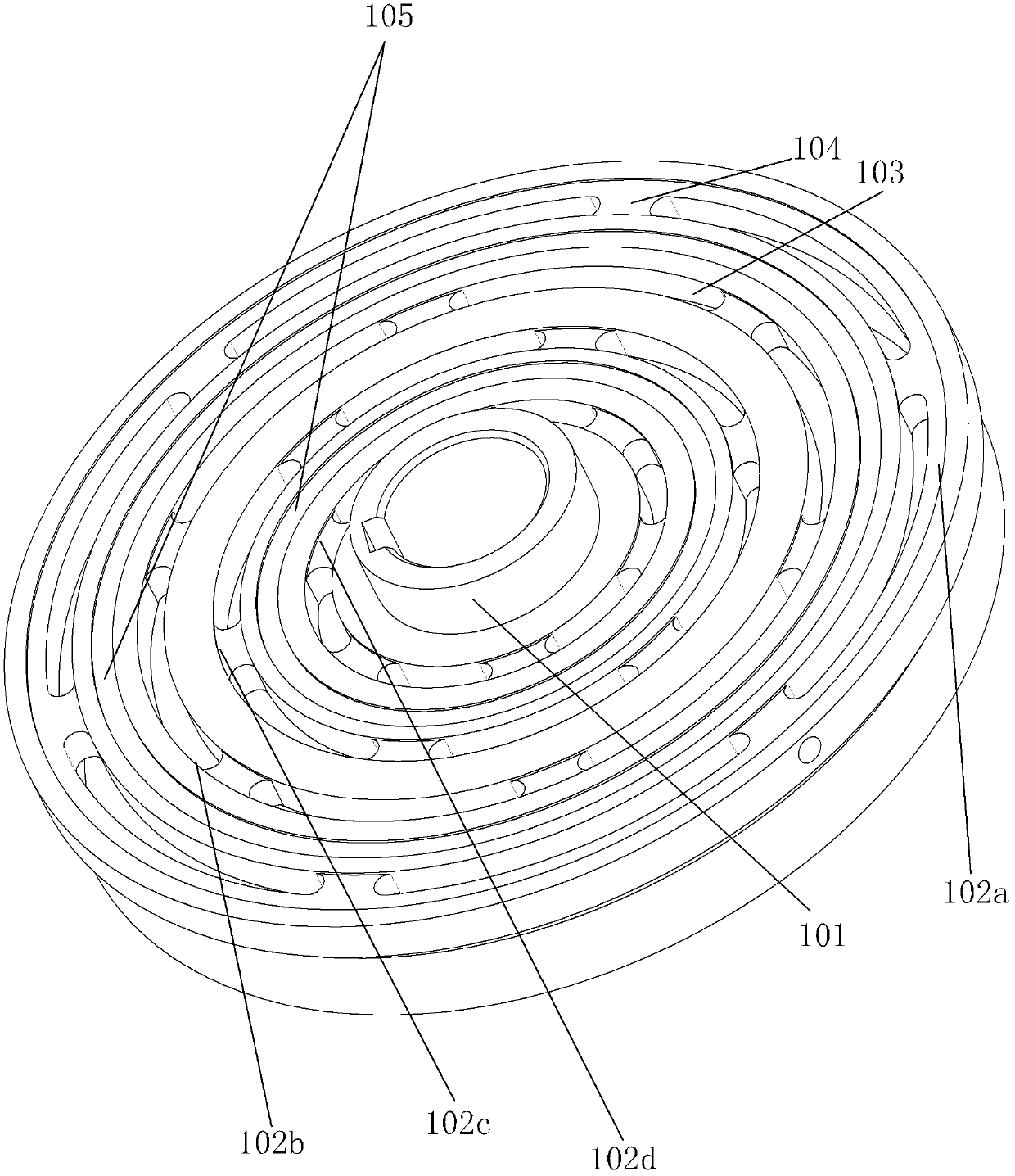

[0074] Example 2 as Figure 6 shown in Figure 3 to Figure 5 In the case of the other structures of the transmission disc embodiment 1 shown as being similar, a keyway is provided in the shaft sleeve 106 on the transmission disc through hole 101, and an interference fit is formed by pressing the shaft sleeve 106 into the hole in the center of the transmission disc. 108 annular welds at the junction. Through this structure, the processing technology of the through hole of the transmission disc can be simplified, and two parallel processes of processing the shaft sleeve and the processing of the transmission disc can be formed, thereby improving the production efficiency.

Embodiment 3

[0075] Example 3 as Figure 7 As shown, in the case of other structures similar to those of Embodiment 2, the bushing 106 is omitted, and a keyway is provided on the hole wall at the center of the transmission disc to form a through hole 101a of the transmission disc. On the premise of satisfying the performance of the transmission disc, this structure can further reduce the production cost and reduce the weight of the transmission disc.

Embodiment 4

[0076] Example 4 as Figure 8 As shown, in the case of Embodiment 2 with other similar structures, an inner wall 107 surrounding the through hole of the transmission disc is provided in the transmission disc cavity. Two accommodating cavities are formed with the outer wall 107a, so that the transmission plate can adapt to the installation of different electromagnetic cores and electromagnetic coils according to the structure of the electromagnetic clutch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com