Roots gas flowmeter

A technology for gas flowmeters and housings, applied in fixed measuring chambers, etc., can solve problems such as the reduction in the speed of the mandrel and the Roots wheel, the impact on the measurement accuracy of the Roots flowmeter, and the increase in the internal pressure of the housing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

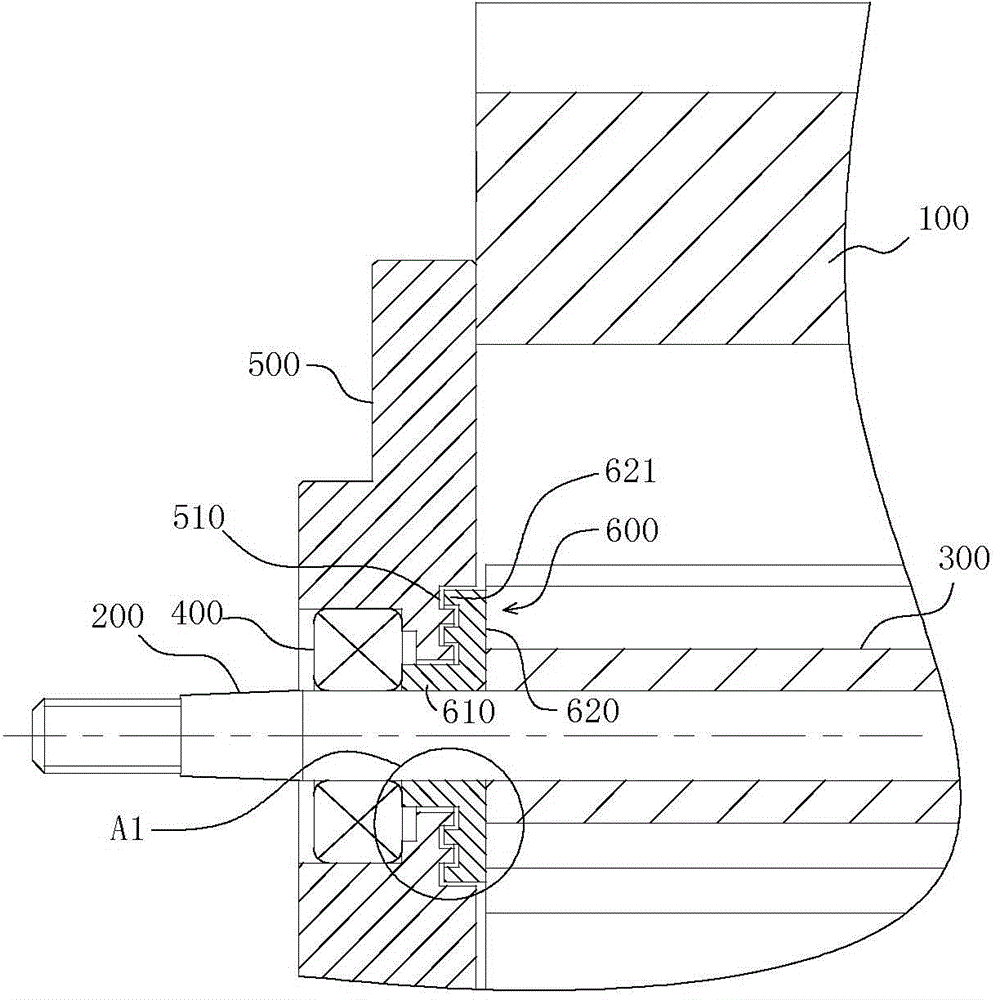

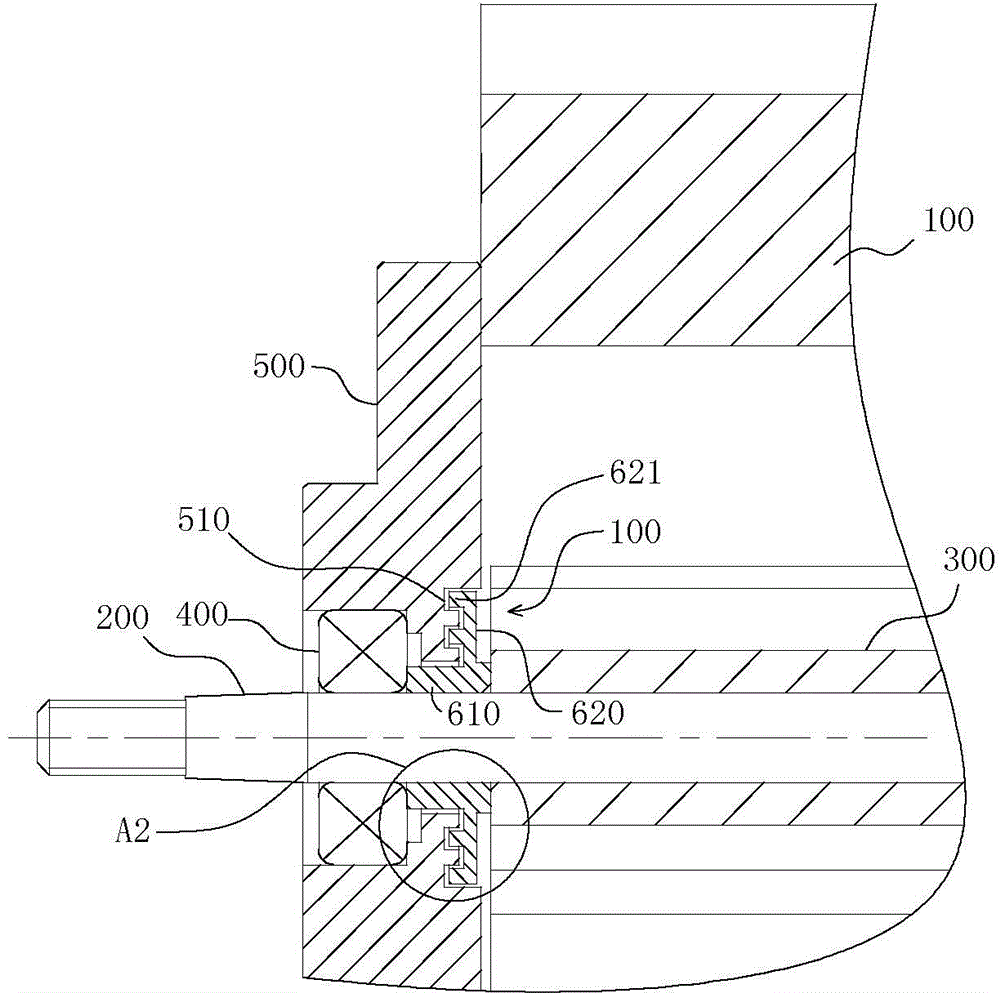

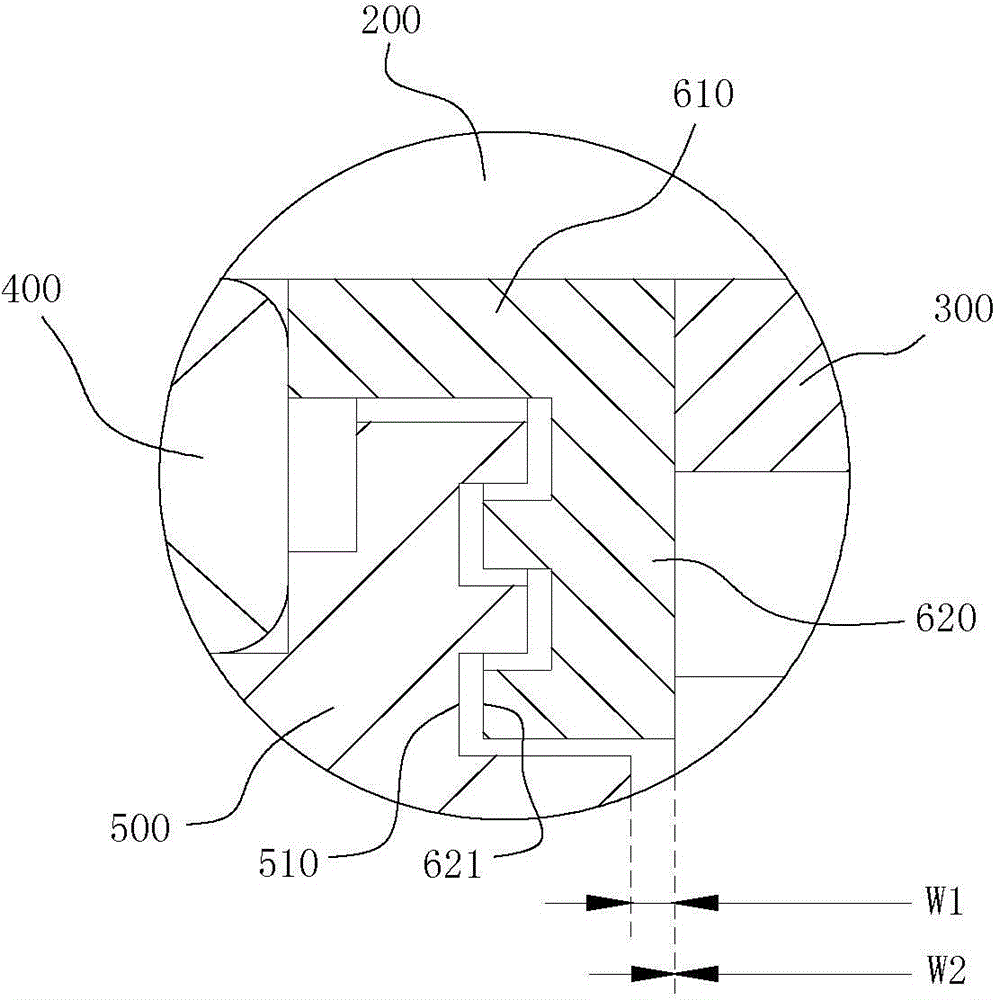

[0012] figure 1 , 3 As shown, the Roots gas flowmeter of Embodiment 1 of the present invention includes a housing 100, a mandrel 200 and a Roots wheel 300, the mandrel 200 is connected to the housing 100 through a bearing 400, and the Roots wheel 300 is installed on the mandrel 200 and set in the housing 100, the side of the housing 100 is also equipped with a pressure plate 500, the bearing 400 is installed on the pressure plate 500, the inner surface of the pressure plate 500 and the end surface of the Roots wheel 300 opposite to the inner surface A first side gap is formed between them, and the width W1 of the first side gap is 0.15 mm; the mandrel 200 is covered with a dust-proof spacer 600, and the dust-proof spacer 600 has a shaft sleeve part 610 and is located on the shaft sleeve part 610. The convex ring portion 620 on the outer cylindrical surface, the sleeve portion 610 is matched with the shaft of the mandrel 200 and the front and rear ends of the sleeve portion 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com