Long-distance oil delivery precise metering control system and control method

A control system and control method technology, applied in the direction of liquid distribution, transportation or transfer device, transportation and packaging, packaging, etc., can solve the problems affecting the measurement accuracy, the number of lifting guns, hydraulic impact, etc., to reduce the volume, prevent lifting The effect of the number of gun jumps and pressure impact and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

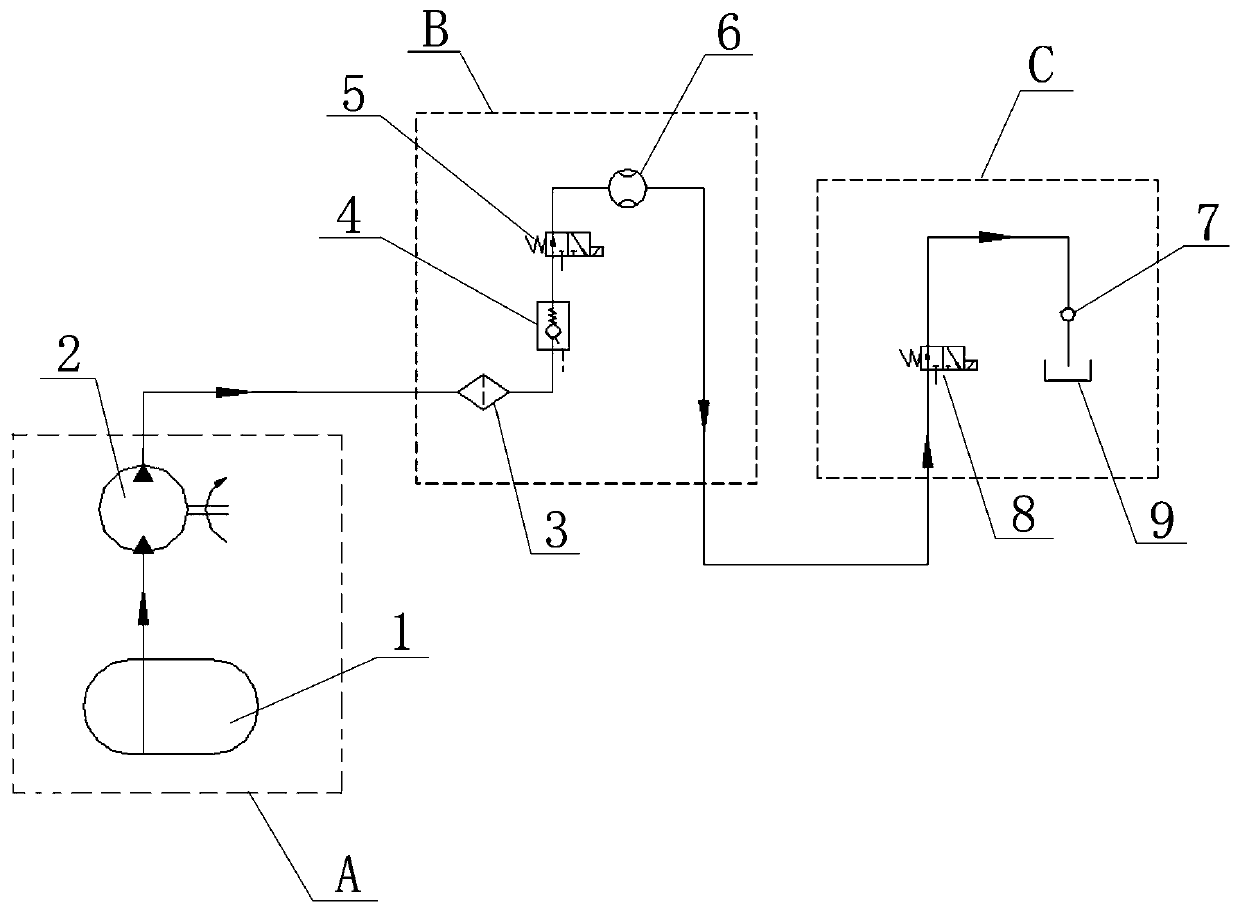

[0028] Embodiment 1: A precise metering control system for long-distance oil delivery, including a control unit, an oil storage unit, a metering unit, and an oil receiving terminal sequentially connected by a buried oil pipeline; the oil storage unit includes an oil tank and a submersible pump ; The metering unit includes a filter, a balance valve, a first solenoid valve and a flow measurement transducer arranged sequentially on the oil delivery pipeline; the oil receiving terminal includes an oil gun, an electrostatically conductive oil hose, and The second solenoid valve at the front end of the rubber hose; the control unit includes a main controller, and the submersible pump, balance valve, first solenoid valve, second solenoid valve, and oil gun are respectively connected to the main controller correspondingly; the flow rate The measuring transducer is correspondingly connected with the main controller through an encoder.

[0029] Wherein, the first solenoid valve and the ...

Embodiment 2

[0030] Embodiment 2: A method for precise metering control of remote oil delivery using the control system in Embodiment 1, comprising the following steps:

[0031] (1) Turn on the switch of the oil gun. After receiving the switch signal of the oil gun, the main controller opens the first solenoid valve and the second solenoid valve, and at the same time sends an oil supply signal to the submersible pump controller to start the submersible pump to supply oil.

[0032] (2) The high-pressure oil in the oil tank is pumped out by the submersible oil pump and delivered to the metering unit through the buried oil pipeline. The oil enters the flow measurement transducer through the filter to push the piston to reciprocate, and the flow measurement transducer drives the encoder in the The indexing plate transmits the generated pulse electric signal to the main controller, and the main controller processes the pulse electric signal to realize the measurement and control of the oil deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com