Upper shaft data monitoring device for weaving workshop

A data monitoring and workshop technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of information lag, variety entry errors, inaccurate data time, etc., and achieve the effect of improving accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

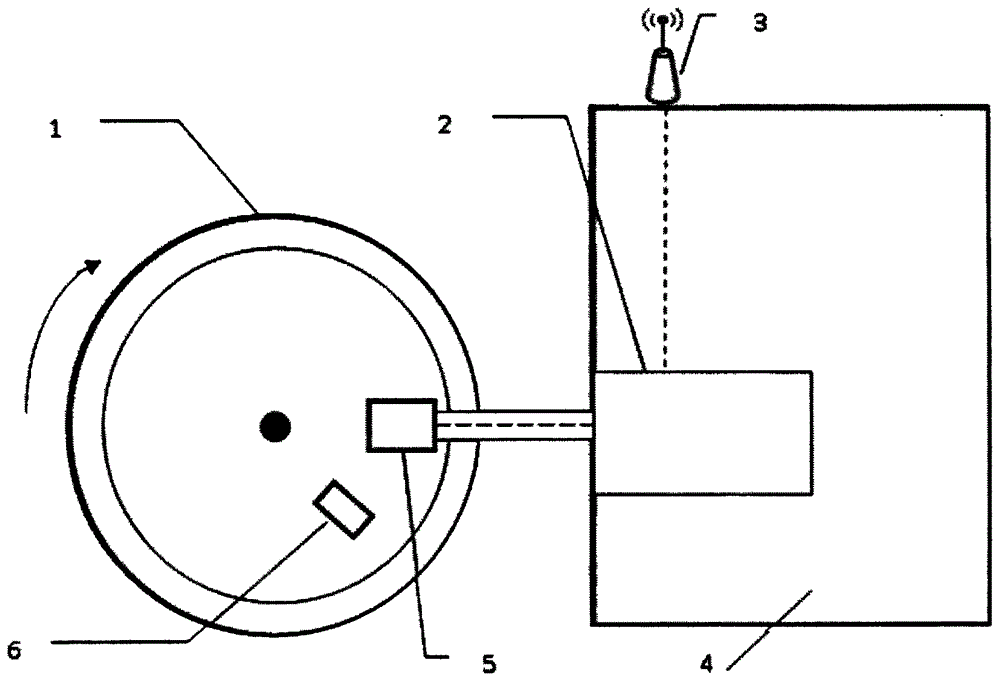

[0015] Such as figure 1 As shown, the present invention designs a set of radio frequency RFID upper shaft card identification and reading system, so that the upper shaft record can be automatically recorded in the steam jet loom system. Firstly, choose an RFID radio frequency card that can store data. Considering the cost and technical requirements, the storage capacity of the selected RFID card memory chip is only 1K. The memory card can be read and written repeatedly.

[0016] This device comprises RFID radio frequency card 6, RFID reader-writer 5, data processing unit 2; Described RFID radio frequency card 6 is installed on the warp beam 1; Described RFID reader-writer 5 is installed on the loom; Described data processing unit 2 Installed on the loom control cabinet 4. A WIFI antenna 3 is also installed on the loom control cabinet 4, and the data processing unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com