A Modeling Method for Complex Equipment System

A modeling method and equipment technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low system reuse efficiency, lack of correlation of views, and model inconsistency, so as to improve design efficiency and ensure Effects of Design Quality, Efficient Concurrent Design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

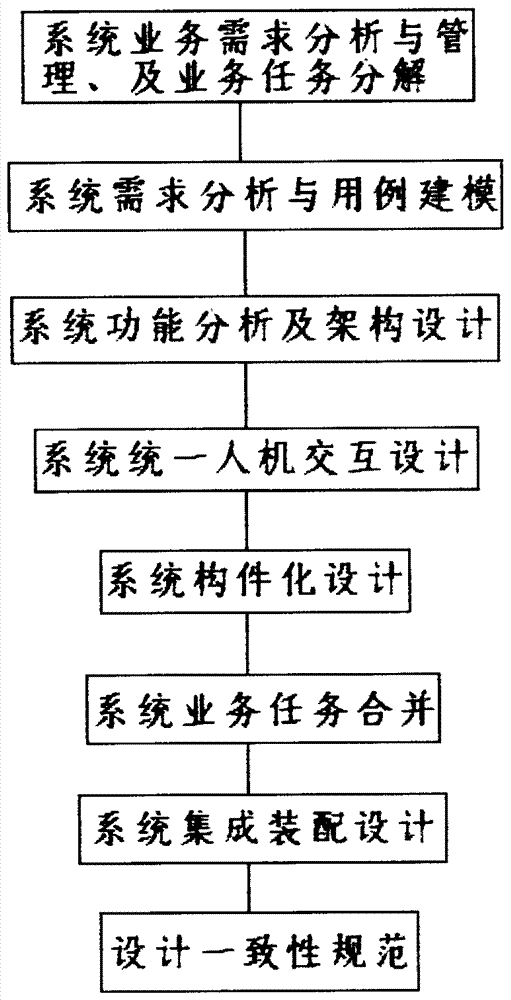

[0119] The following will take the helicopter control system as an example to further describe the technical solution of the present invention in detail: according to the business process-driven design concept, its goal is to assist the design team to carry out system business demand analysis, system demand analysis, and system function analysis in parallel or iteratively , architecture design, unified human-computer interaction design, component design and integrated assembly design. Through the definition and specification of the whole life cycle design activities, the integration of requirements analysis, system design and application integration is truly realized, so as to improve design efficiency, ensure design quality, and give full play to the comprehensive advantages of the system.

[0120] (1) Analysis and management of X-type helicopter control system business requirements, and business task decomposition:

[0121] a. Document X-Helicopter Control System Mission Requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com