Mold fixer of slipform paver

A slip-form paver and fixer technology, which is applied in roads, road repairs, roads, etc., can solve the problems that the inclination angle of the mold cannot be automatically adjusted, it is difficult to adapt to road construction, and the efficiency of replacing and installing the mold is low, so as to achieve high efficiency and speed Replacement and installation, fast and easy replacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

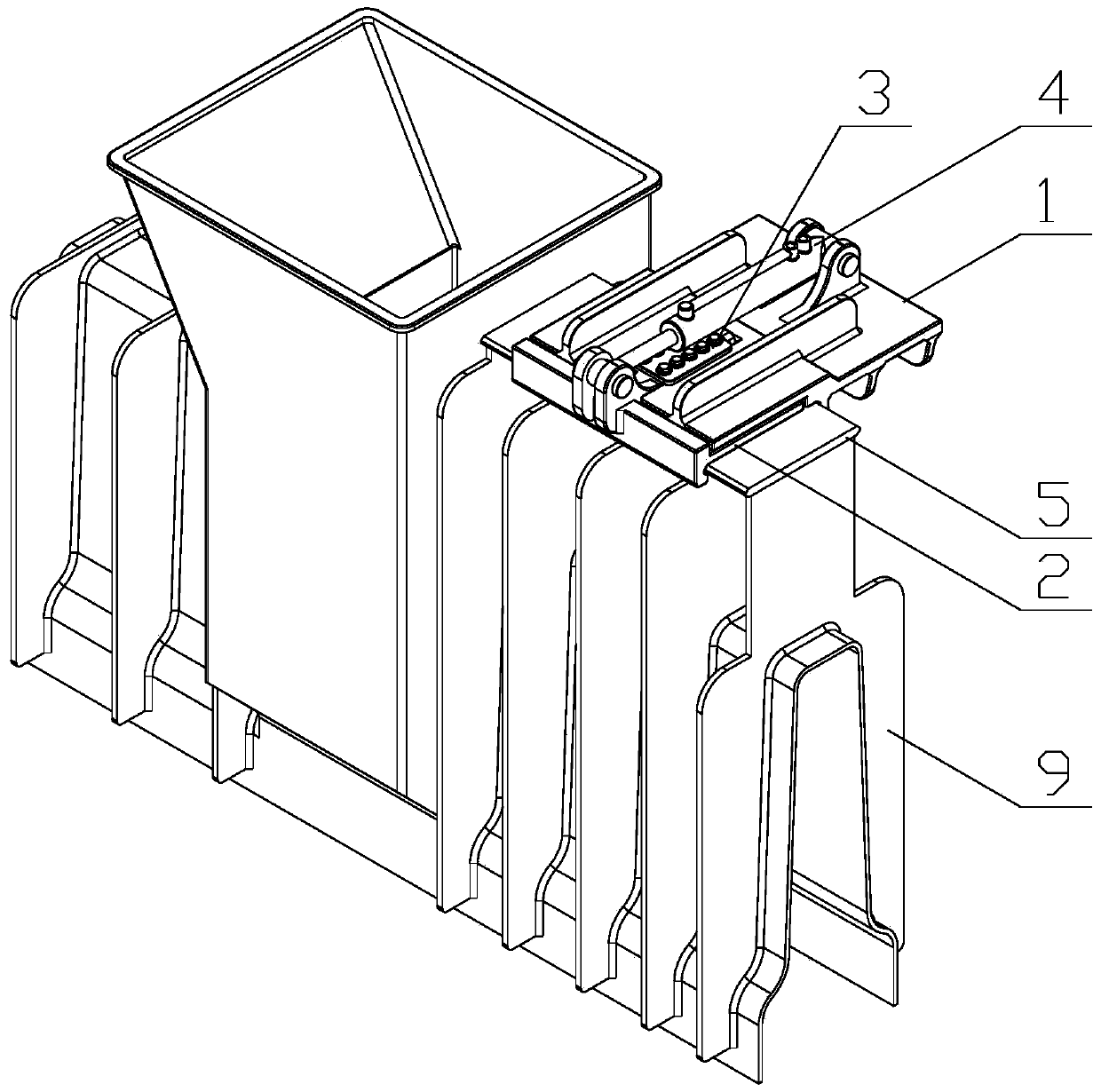

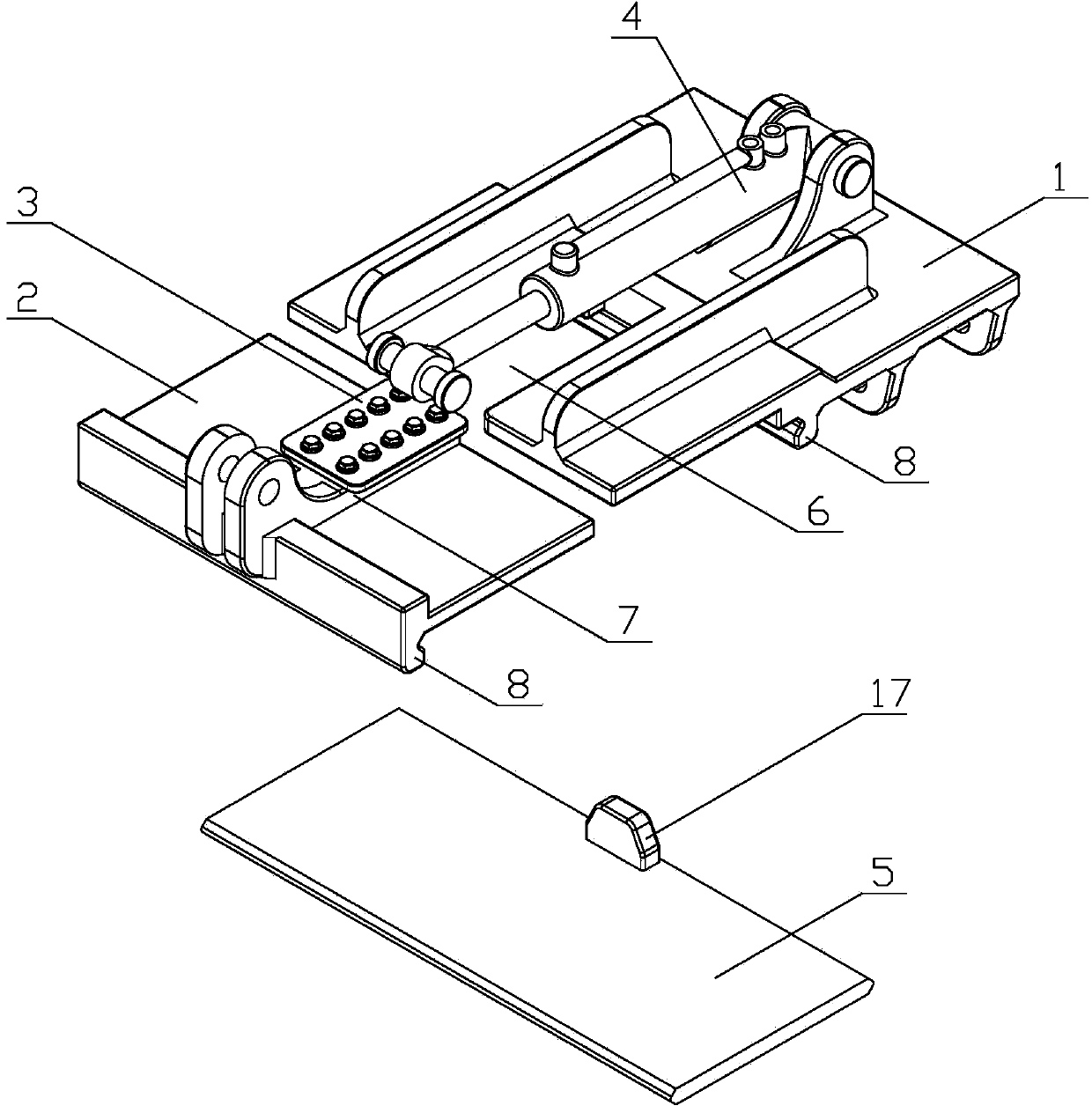

[0014] Embodiment 1: as figure 1 with figure 2 As shown, the slipform paver mold holder includes a holder bottom plate 1, a movable splint 2, a splint limit block 3, a holder oil cylinder 4, and a sliding form connecting plate 5; Slideway 6 is provided with a limit slide 7 at the top of the movable splint 2, and the limit slide 7 is slidably inserted in the slideway 6, and the top surface of one end of the movable splint 2 is in sliding contact with the bottom surface of the holder base plate 1; The top surface of the slide table 7 is provided with a splint limit block 3, and the bottom surface of the splint limit block 3 is in sliding contact with the top surface of the holder base plate 1; The top of the piston rod of the oil cylinder 4 is connected with the top of the movable splint 2 through a pin shaft; through the expansion and contraction of the fixer oil cylinder 4, the limit slide 7 of the movable splint 2 slides along the slideway 6, and the splint on the limit sli...

Embodiment 2

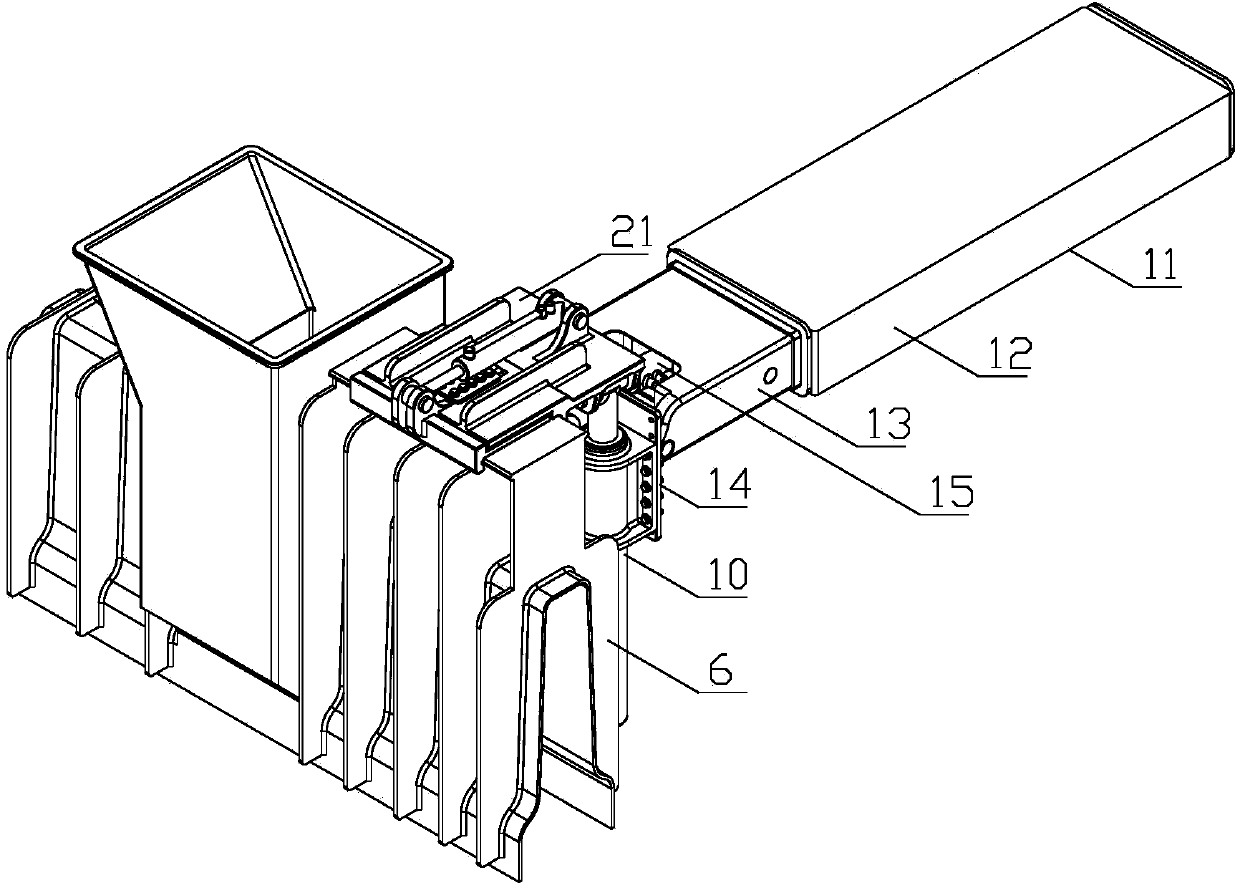

[0015] Embodiment 2: as image 3 As shown, the mold holder for a slipform paver includes a holder base plate 1, a movable splint 2, a splint limit block 3, a holder cylinder 4, a sliding form connecting plate 5, two lifting cylinders 10 and a horizontal telescopic support 11 ;Such as figure 1 As shown, a slideway 6 is provided at one end of the fixture bottom plate 1, and a limit slide 7 is provided at the top of the movable splint 2, and the limit slide 7 is slidably inserted in the slideway 6, and the top surface of the movable splint 2 is It is in sliding contact with the bottom surface of the holder bottom plate 1; a splint limit block 3 is provided on the top surface of the limit slide table 7, and the bottom surface of the splint limit block 3 is in sliding contact with the top surface of the holder bottom plate 1; the cylinder body of the holder oil cylinder 4 It is connected with the top of the holder bottom plate 1 through a pin shaft, and the top of the piston rod o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com