Method for determining medium-and-large-radius track of two-dimensional small-pre-target-displacement horizontal well

A technology of target distance and horizontal well, which is applied in the field of petroleum drilling, can solve the problems of increasing drilling footage, increasing reverse displacement, increasing construction difficulty and drilling cost, etc., to achieve increasing drilling footage, increasing reverse displacement, increasing construction difficulty and drilling cost cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

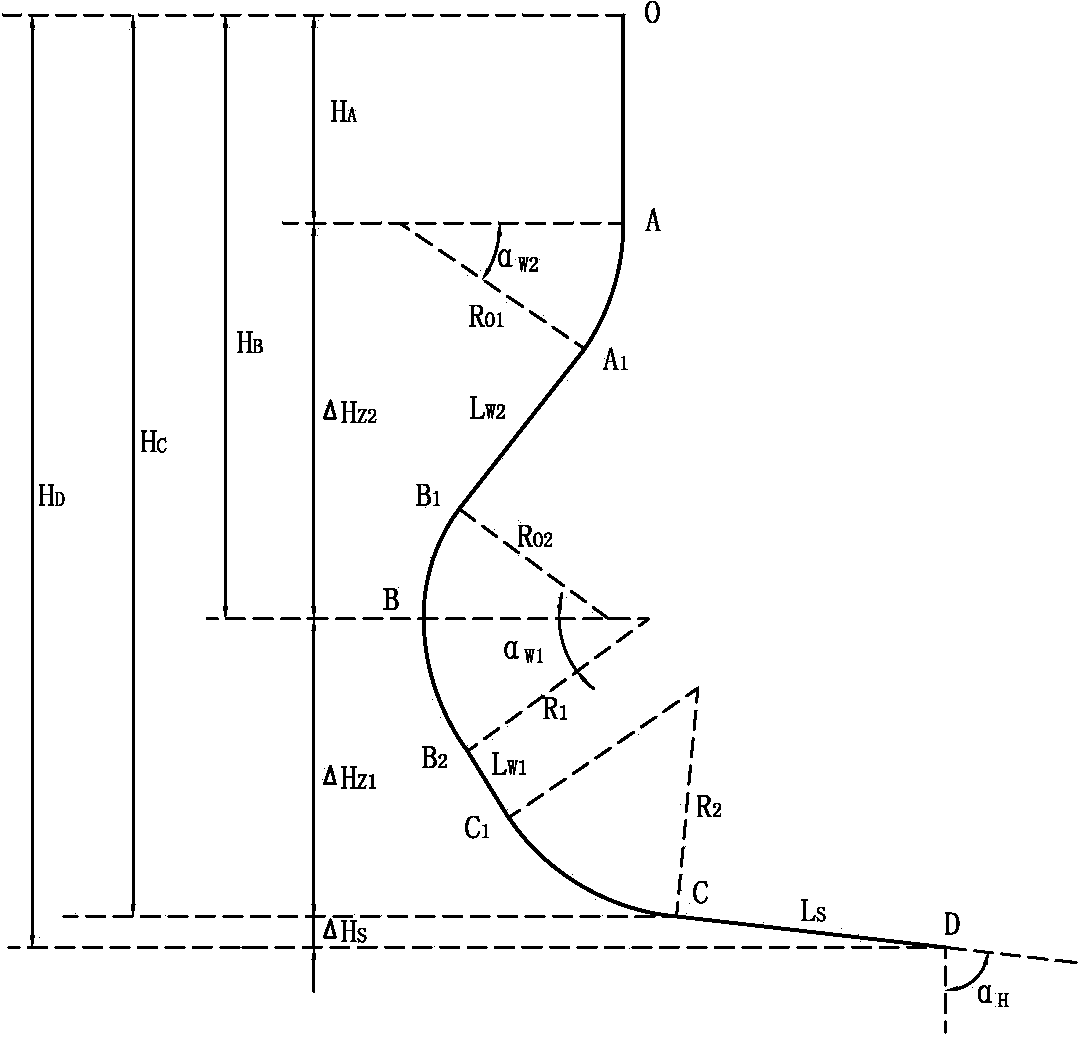

[0036] Determine the long-medium radius orbit from the horizontal well in front of a two-dimensional small target, step (1): determine the first target point C, the second target point D and the wellhead position O.

[0037] Step ⑵: Obtain the displacement of the first target point =81.18 meters, vertical depth of the first target point =2258.16 meters, second target point displacement =304.61 meters and the vertical depth of the second target point =2263.23 meters.

[0038] Step ⑶: Due to the displacement of the first target point =81.18m, less than 86m, go to step ⑷.

[0039] Step (4): Determine the third part of the horizontal section track, and the horizontal section track extends along the connecting line between the first target point C and the second target point D. Determine the length LS of the horizontal segment track: Meter;

[0040] Determine the well inclination of the horizontal section of the track: Spend;

[0041] Determine the displacement of t...

Embodiment 2

[0073] In the range of medium and long radii, use arcs with shorter radii as inclination or declination arcs, select R1= R2=191 meters, RO1=212.21 meters, RO2=229.18 meters, and obtain the horizontal well trajectory according to the above steps The parameters are shown in Table 2:

[0074] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com