Cylindrical surface interference splicing measuring device and adjusting method thereof

A technology of measuring device and adjustment method, applied in the direction of measuring device, using optical device, instrument, etc., can solve the problems of installation and adjustment mechanism and its adjustment method that have not been reported in relevant literature, and achieve the effect of accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

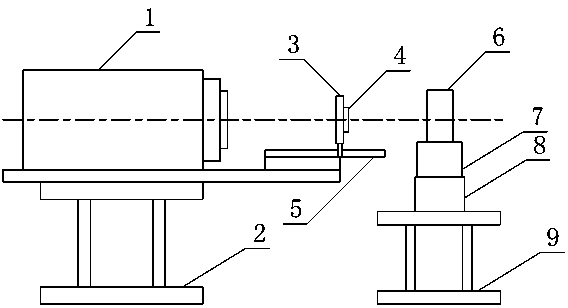

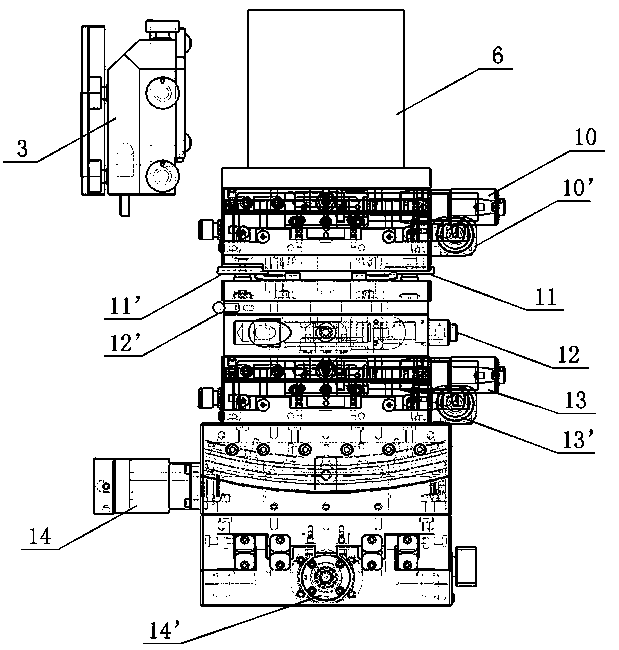

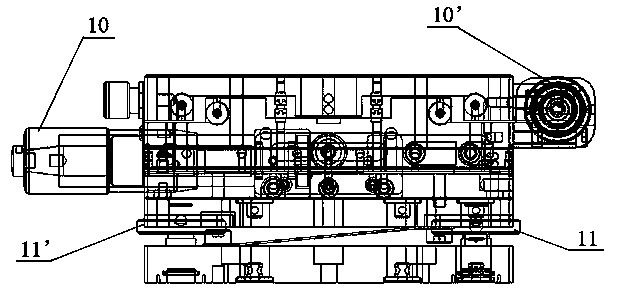

[0031] Such as figure 1As shown, a cylindrical interference splicing measurement device includes an interferometer (1), a support (2), a six-dimensional adjustment frame (3), a CGH (4), a one-dimensional guide rail platform (5), and a test piece ( 6), four-dimensional adjustment mechanism (7), five-dimensional adjustment mechanism (8), electric control lifting platform (9). It is characterized in that: the interferometer (1) and the one-dimensional guide rail platform (5) are installed on the support (2), the six-dimensional adjustment frame (3) is installed on the one-dimensional guide rail platform (5), and the CGH (4) is installed On the six-dimensional adjustment frame (3), the exit optical axis of the interferometer (1) can pass through the center of the CGH (4), and the distance between the CGH (4) and the measured object (6) can be adjusted; by the four-dimensional The adjustment mechanism (7), the five-dimensional adjustment mechanism (8) and the electric control lift...

Embodiment 2

[0039] A method for adjusting a cylindrical surface interference splicing measurement device, used for adjusting the cylindrical surface interference splicing measurement device according to claim 1, characterized in that the operation steps are as follows:

[0040] ① Install and adjust CGH (4): CGH (4) is installed on the six-dimensional adjustment frame (3), and the six-dimensional adjustment frame (3) is installed on the one-dimensional guide rail platform (5); firstly, adjust the CGH (4) and The distance between the tested parts (6) is such that the distance between the CGH (4) and the axis of the measured cylindrical workpiece is the back focal length of the CGH (4); secondly, adjust the six-dimensional adjustment frame (3) so that the interferometer (1) The outgoing optical axis passes through the center of the CGH (4) and deflects it by 1 degree relative to the optical axis. By adjusting the position of the marking point of the CGH (4), the focal line of the cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com