Rotor feeding device

A technology of feeding device and rotor, which is used in the manufacture of stator/rotor body, etc., can solve the problems of the influence of assembly line production, slippery jam, easy jamming, etc., and achieves the effect of ensuring normal transfer and preventing jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

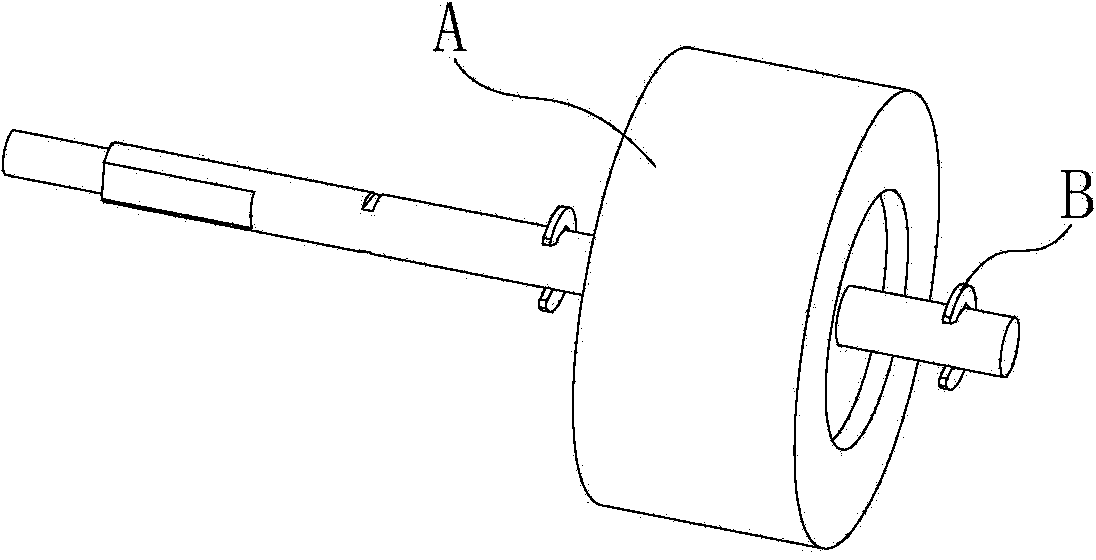

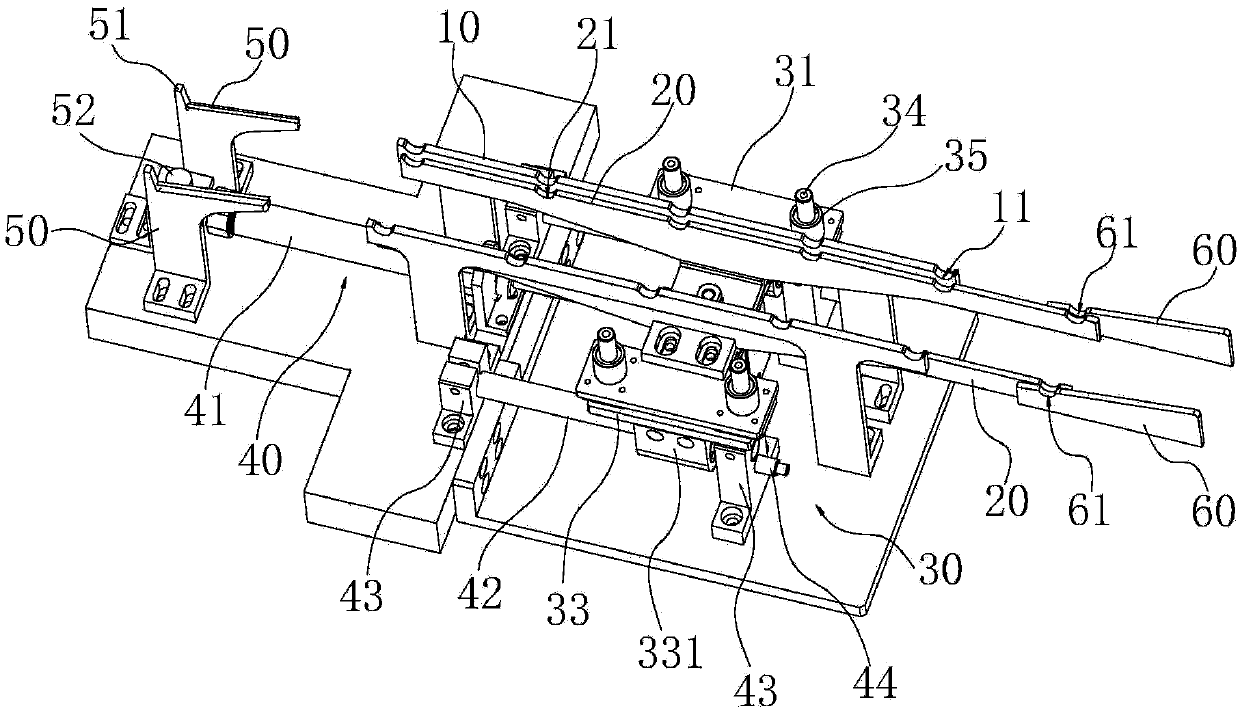

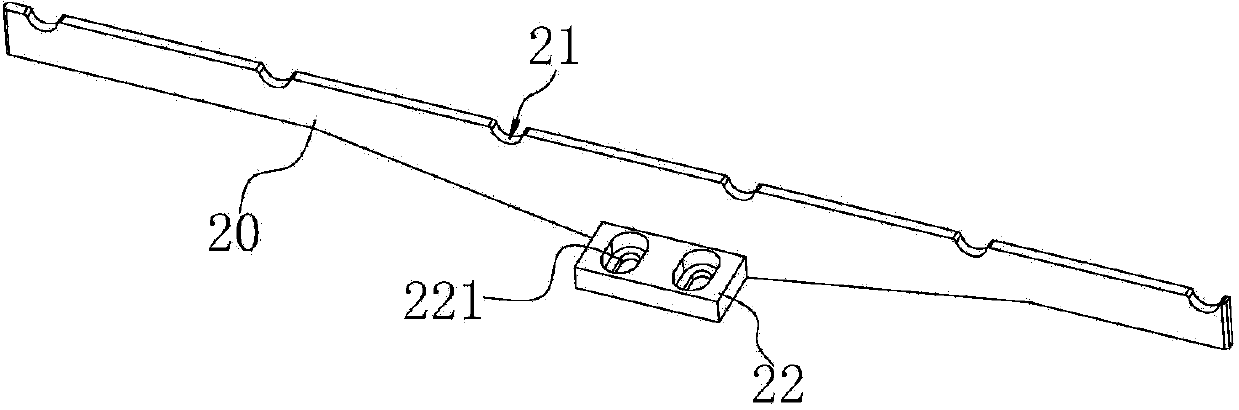

[0013] Combine below Figure 1 to Figure 9 , the present invention is further described:

[0014] A rotor feeding device, comprising two supporting frames 10 arranged at intervals on the machine base, the upper ends of the two supporting frames 10 are correspondingly provided with positioning grooves 11, the device also includes two moving frames 20 arranged at intervals, the moving The length direction of the frame 20 is parallel to the length direction of the support frame 10 and the upper end is provided with a card slot 21. The mobile frame 20 is arranged on the lifting unit 30, and the lifting unit 30 drives the mobile frame 20 to present the card slot 21 when it is lifted to the highest position. The bottom is higher than the upper end surface of the support frame 10 and the upper end surface of the mobile frame 20 is lower than the bottom of the positioning groove 11 of the support frame 10 when it is lowered to the lowest position. The mobile frame 20 is also connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com