Patents

Literature

36results about How to "No scrolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Speaker

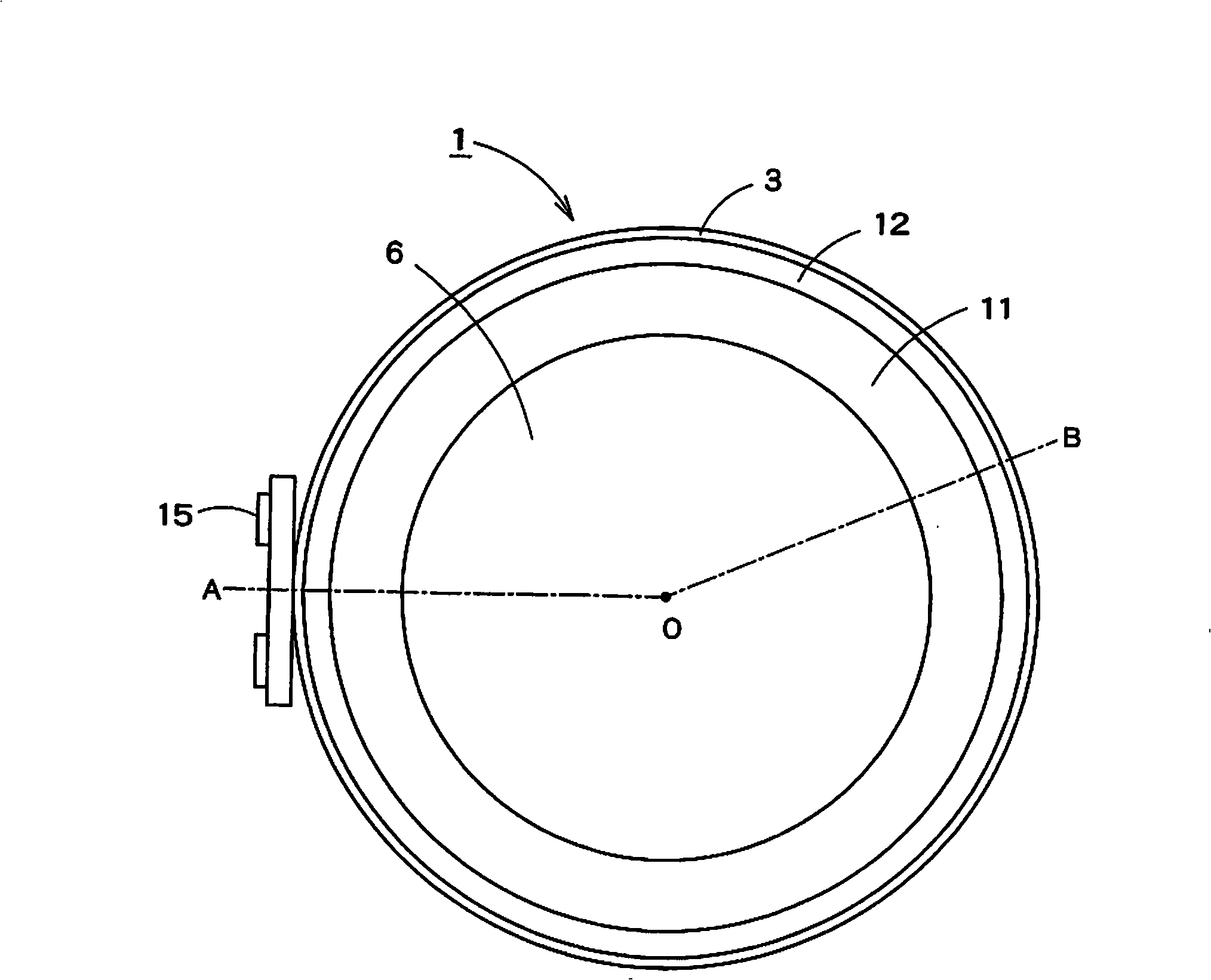

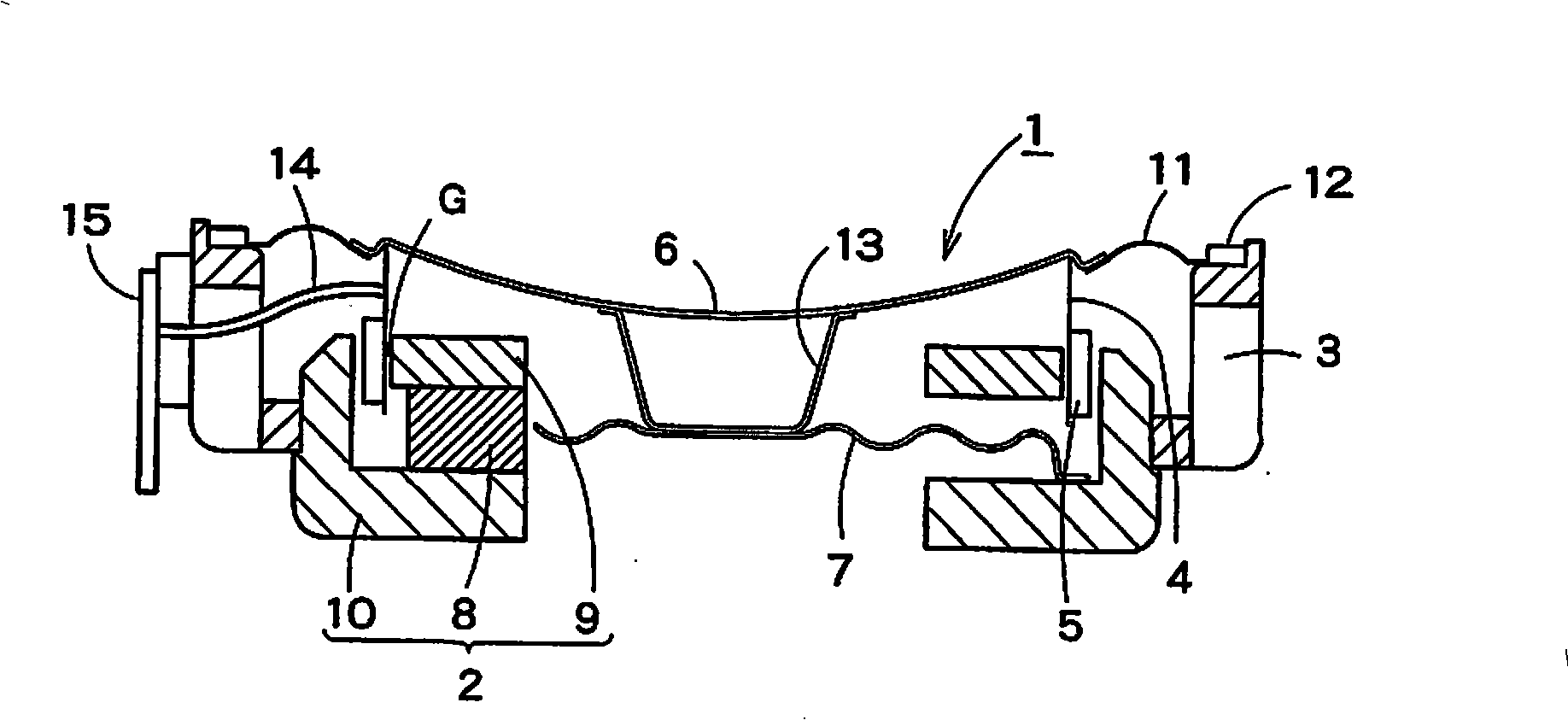

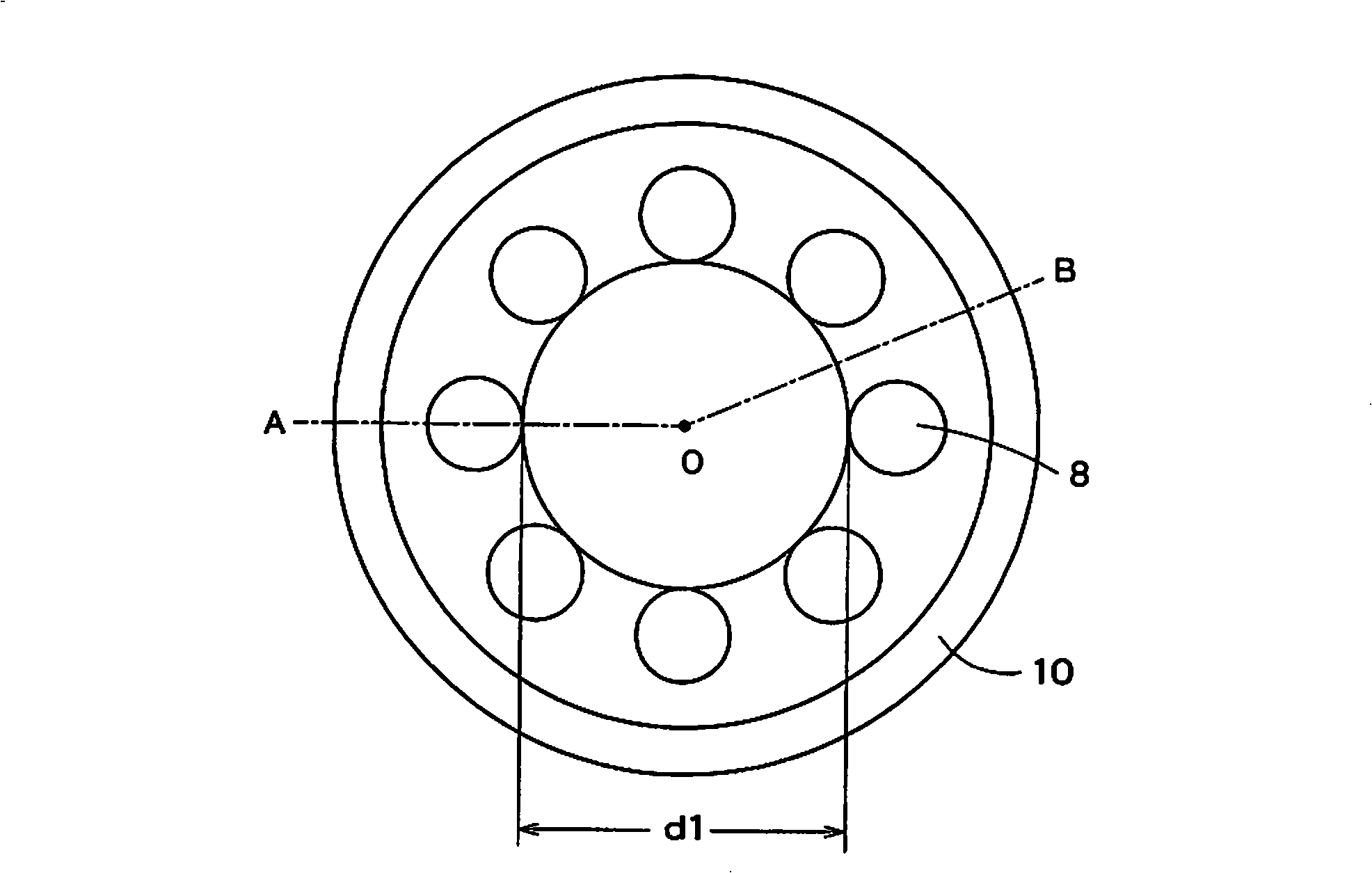

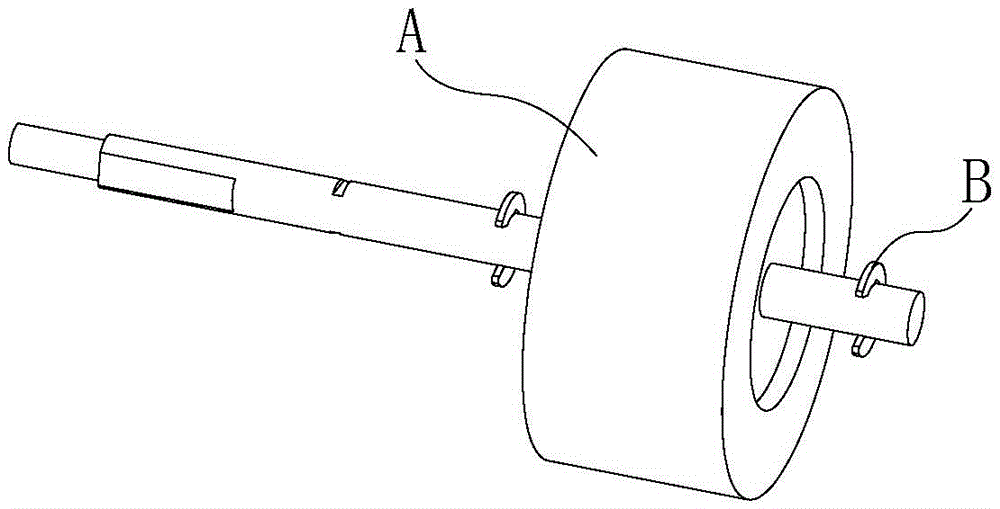

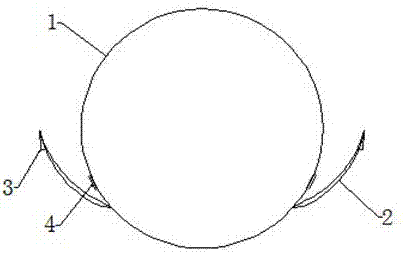

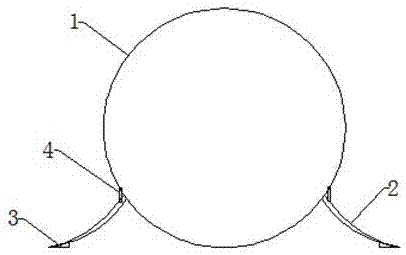

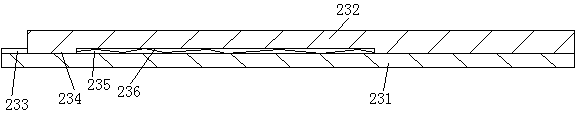

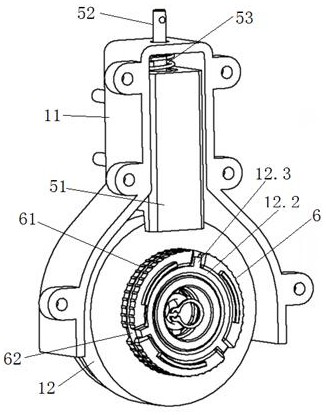

InactiveCN101257731ANo scrollingWide playback frequency rangeDiaphragm mounting/tensioningBobbinPole piece

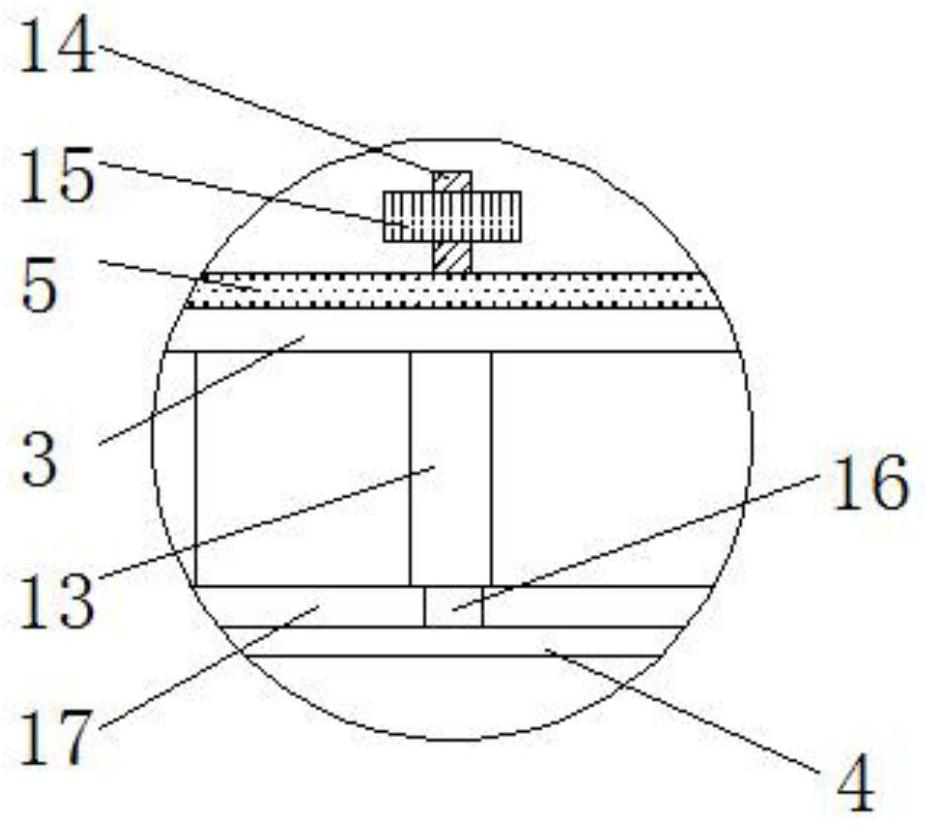

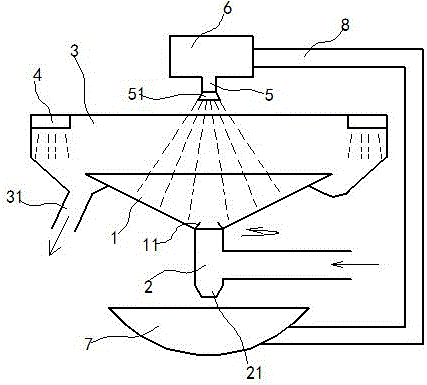

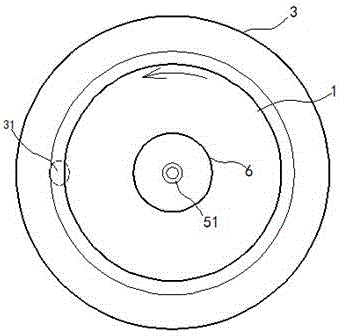

A speaker includes: a magnetic circuit; a voice coil bobbin; a voice coil; a diaphragm; a frame to which the outer circumference of the diaphragm is connected via a suspension; and a spider to support the center area of the diaphragm. A magnet unit, a pole piece, a pole piece, and a yoke are included in the magnetic circuit. The yoke has a ring shape with a center opening, and is disposed at the rear of the magnet unit. The magnet unit has a ring structure having a plurality of empty portions arranged equiangularly, and the spider includes a main body and a plurality of legs extending radially outwardly from the main body and is disposed inside the magnetic circuit such that distal end tips of the legs pass beyond the inner diameter of the ring structure of the magnet unit.

Owner:MINEBEA CO LTD

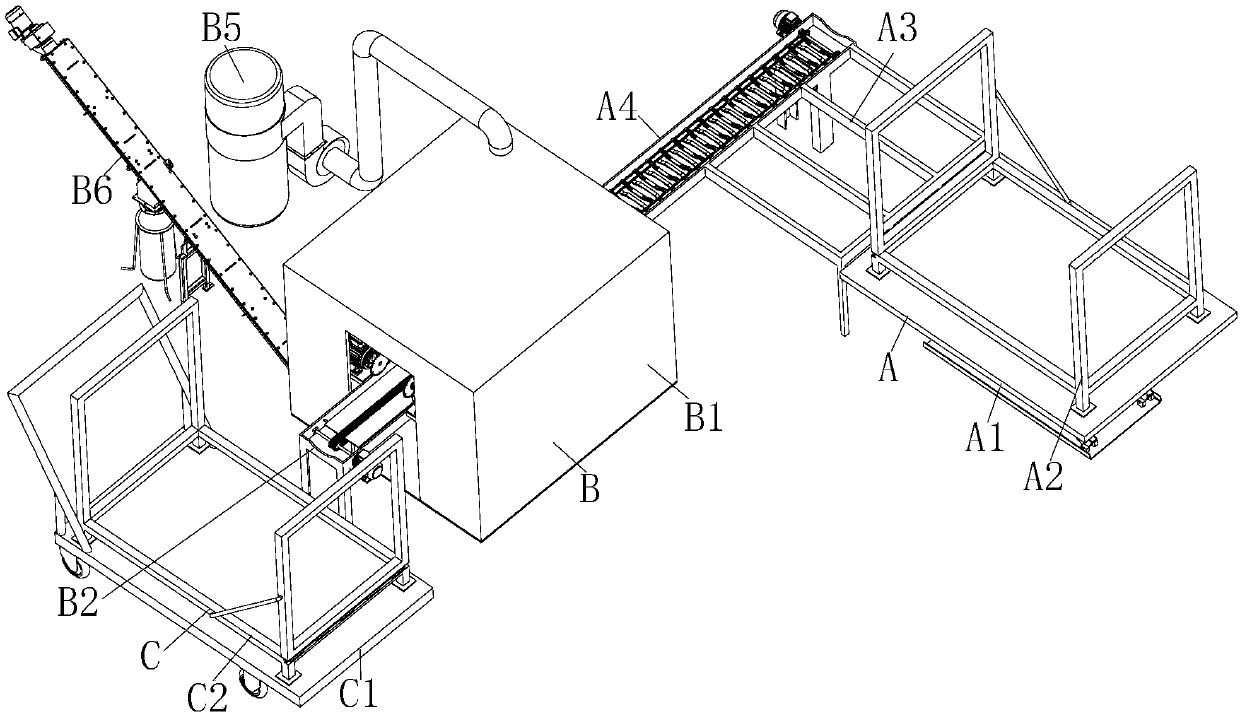

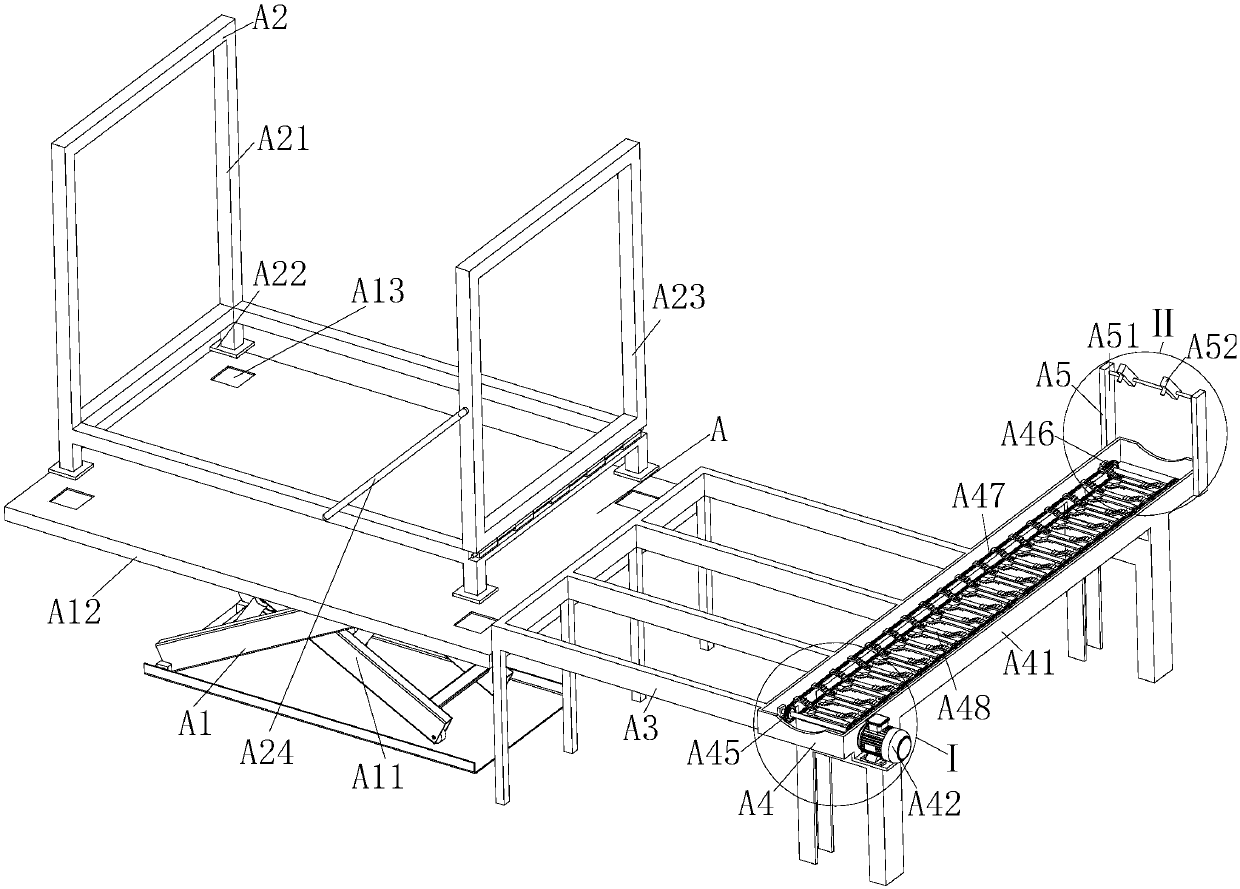

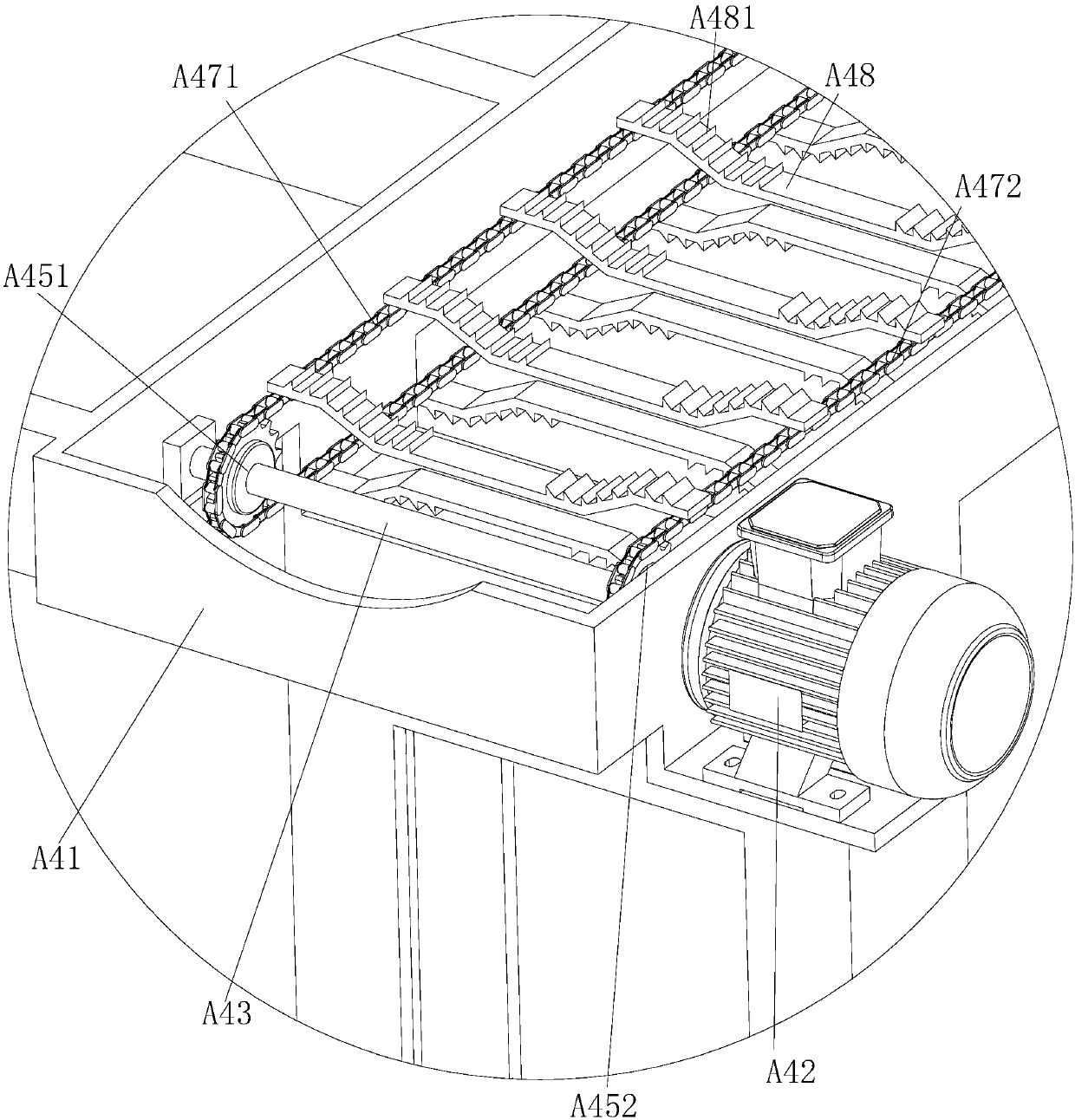

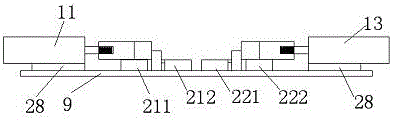

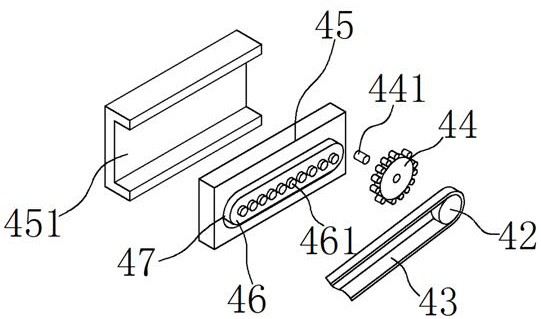

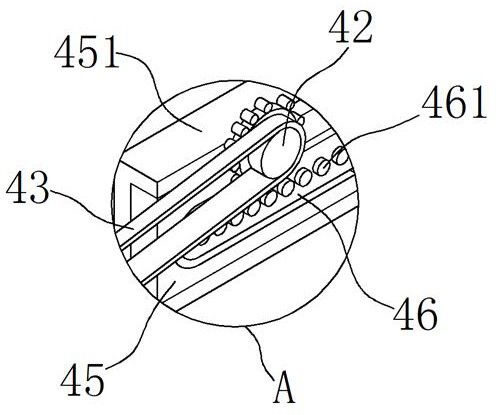

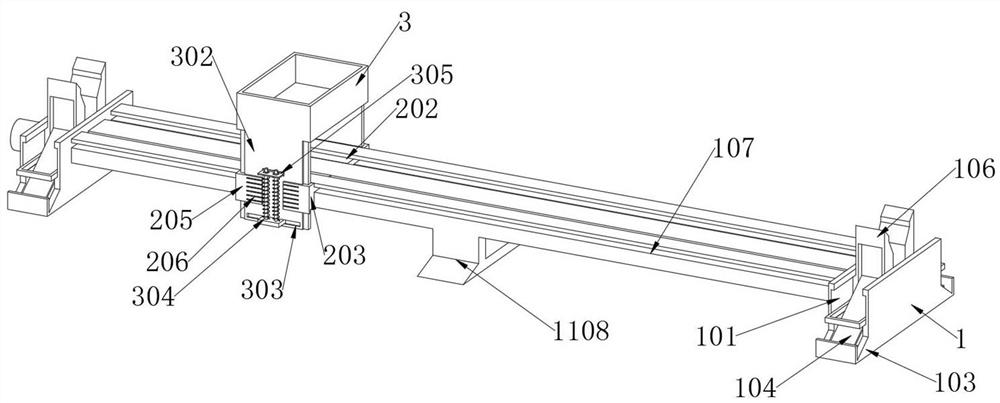

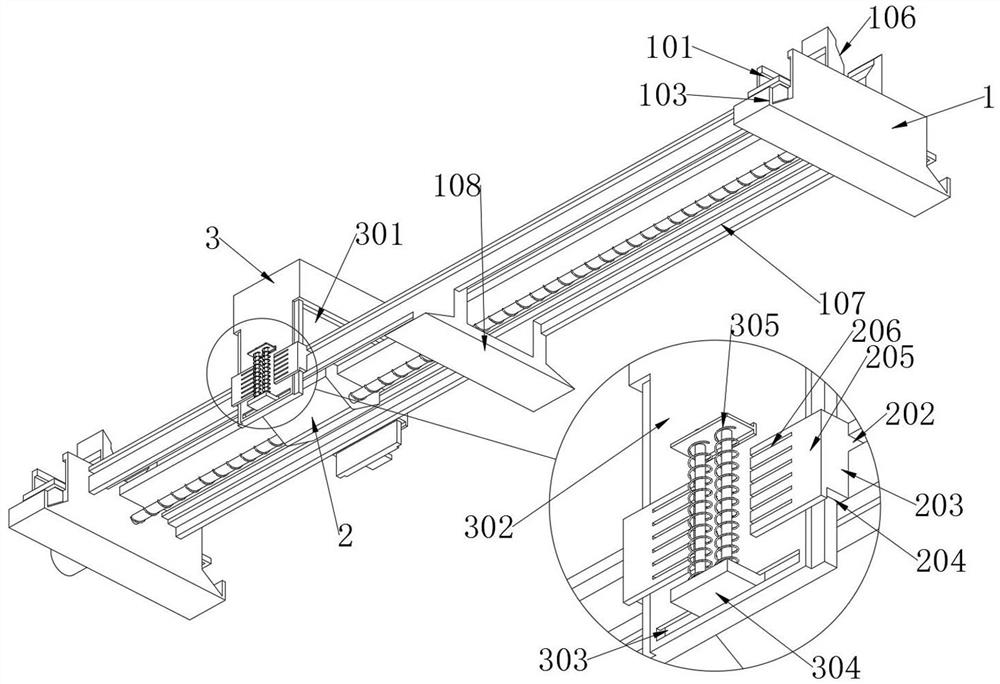

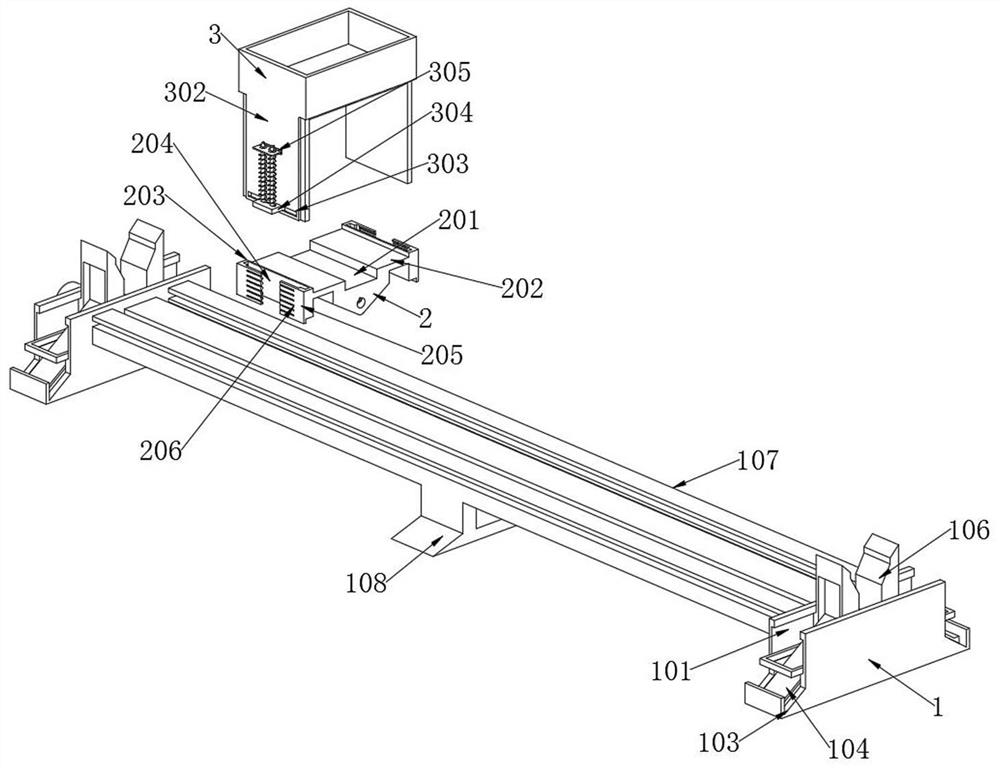

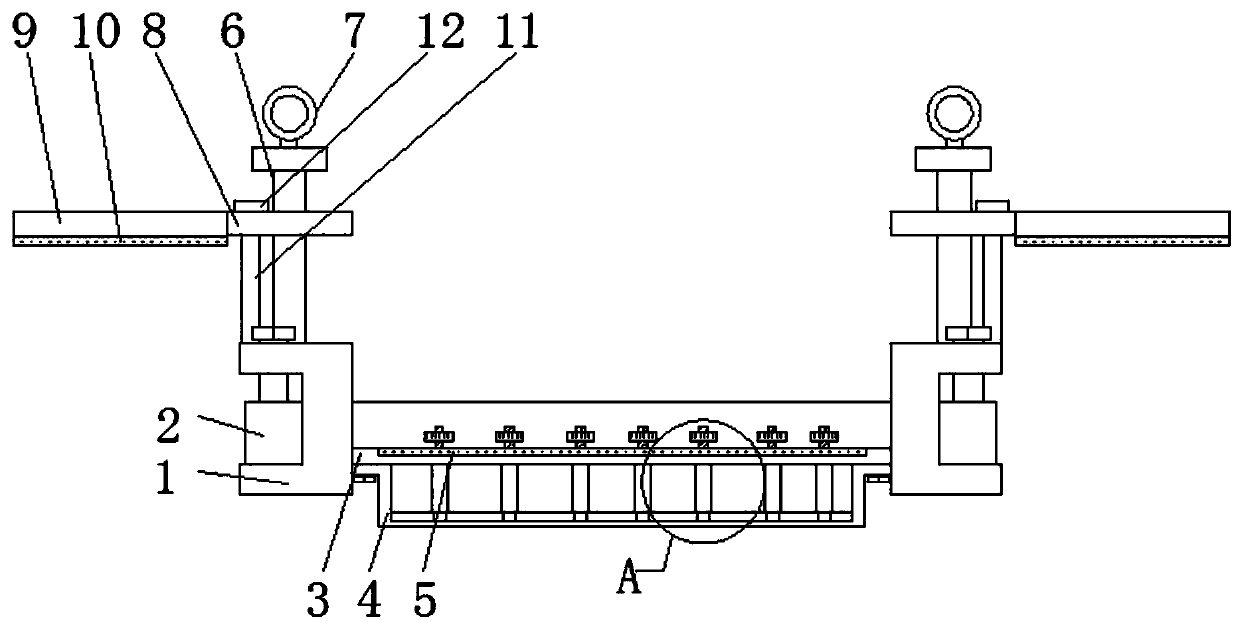

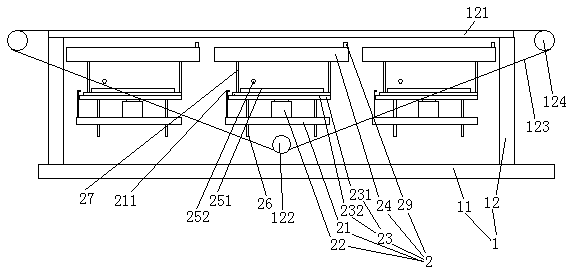

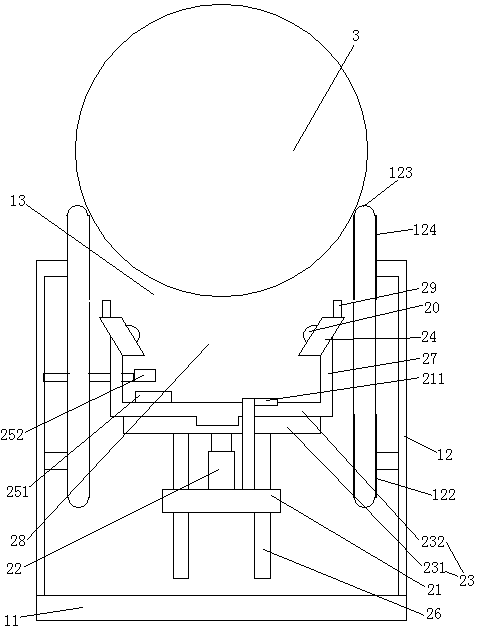

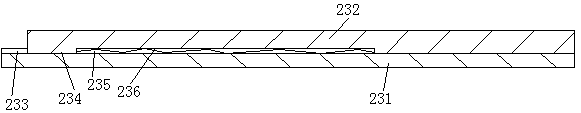

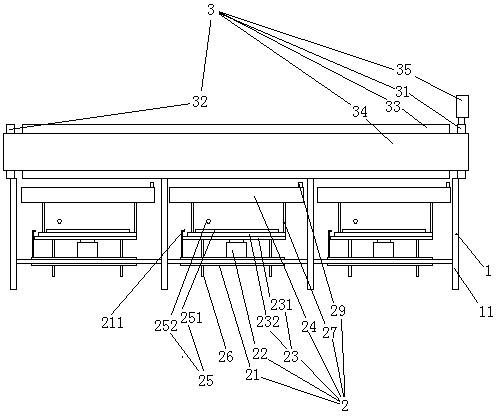

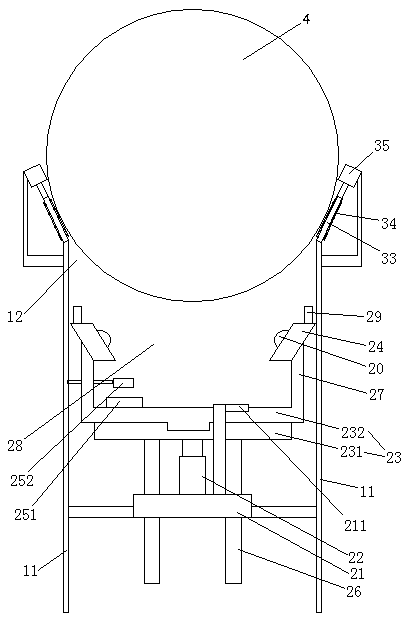

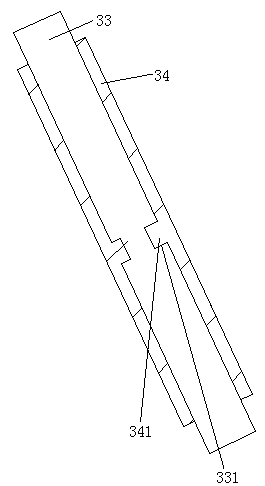

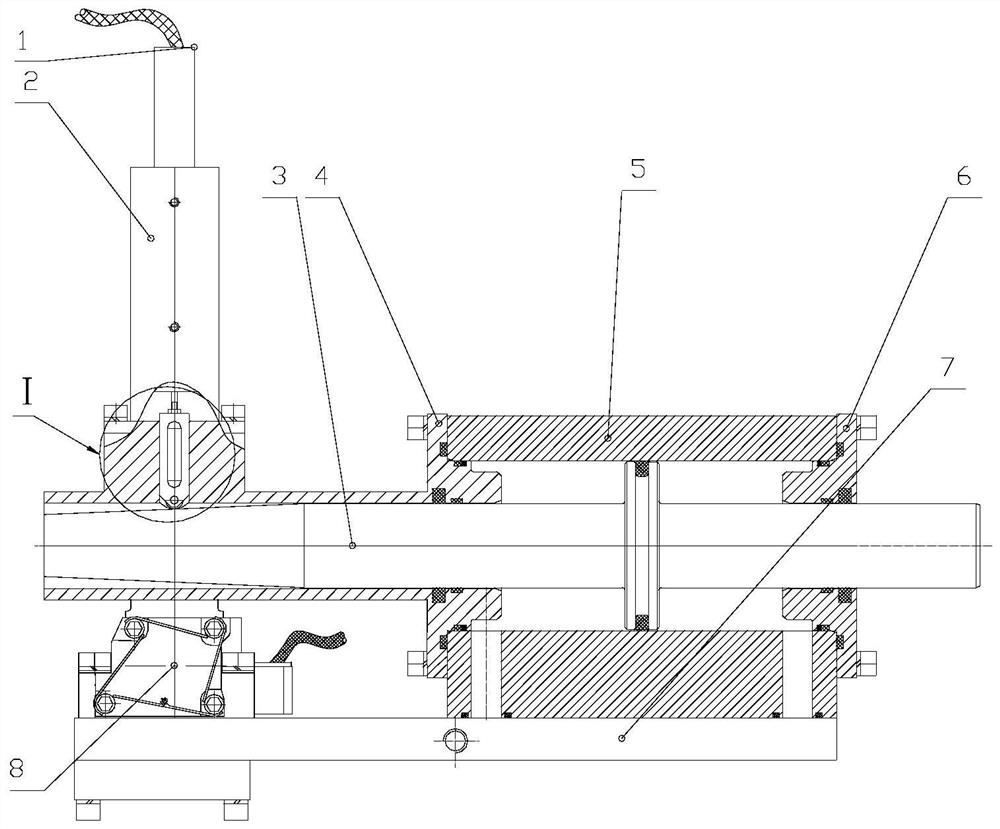

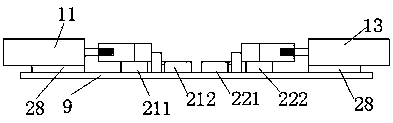

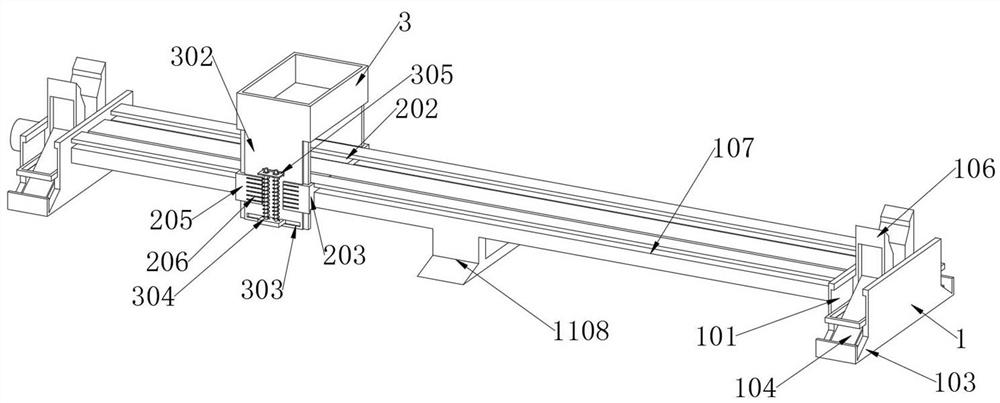

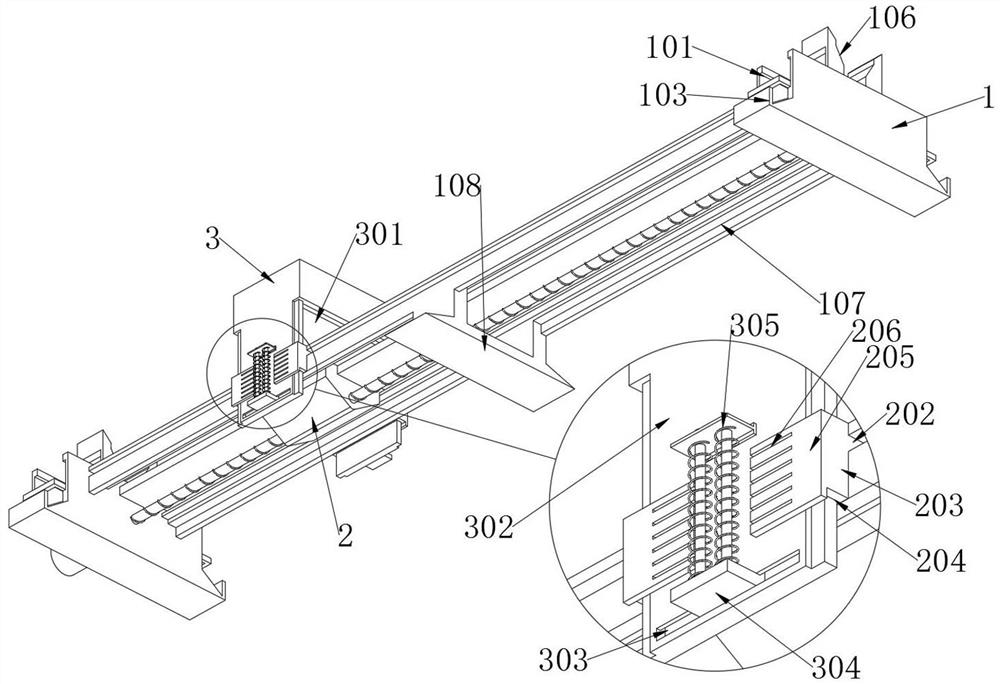

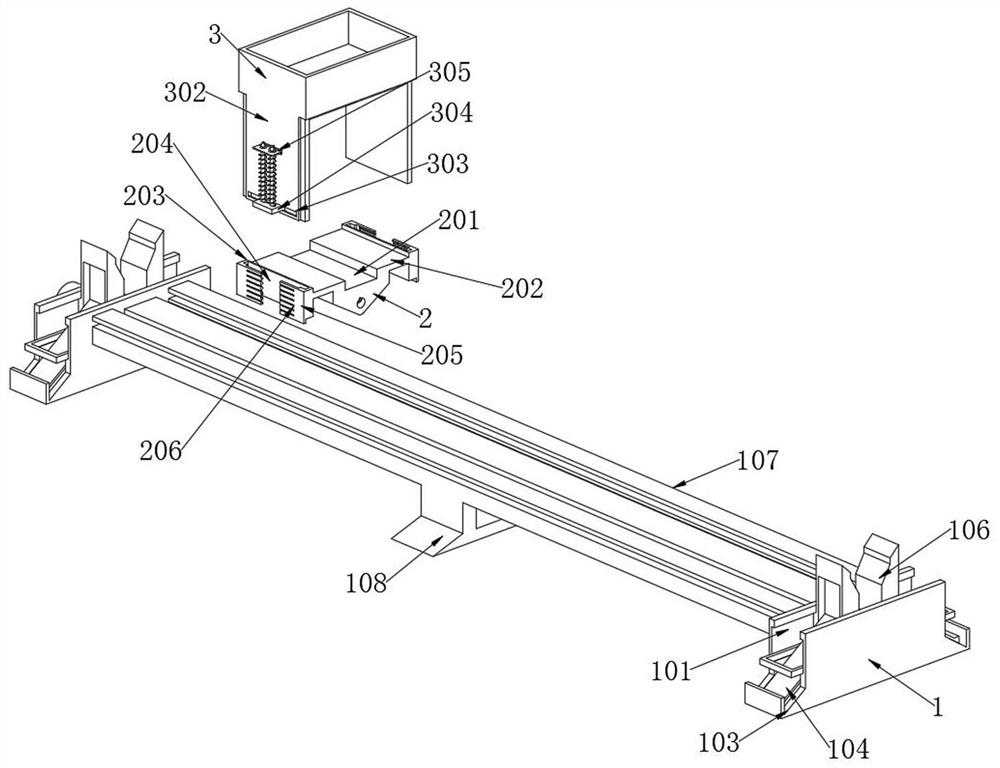

Automatic multifunctional raw wood cutting machine and cutting method

InactiveCN107627398AIncrease productivityReduce manufacturing costCircular sawsBark-zones/chip/dust/waste removalEngineeringManual handling

The invention relates to an automatic multifunctional raw wood cutting machine and a cutting method, which belong to the field of wood processing. The automatic multifunctional raw wood cutting machine is usually applied to wood processing, and in the prior art, a single wood to be processed is carried to the cutting machine so as to be cut, dust produced during a cutting process flies about, woodbits are hard to collect, the environment is polluted, and the health of workers is influenced. The automatic multifunctional raw wood cutting machine comprises a feeding device, a cutting device anda conveying device, wherein the feeding device is connected with one side of the cutting device; and the conveying device is placed at the other side of the cutting device. Manual handling is not needed, and multiple woods to be processed can be loaded every time, so that the production efficiency is improved; and the humidity of the woods to be processed is increased, so that the dust produced during the cutting process cannot fly about, and the environment cannot be polluted.

Owner:浙江林达包装科技股份有限公司

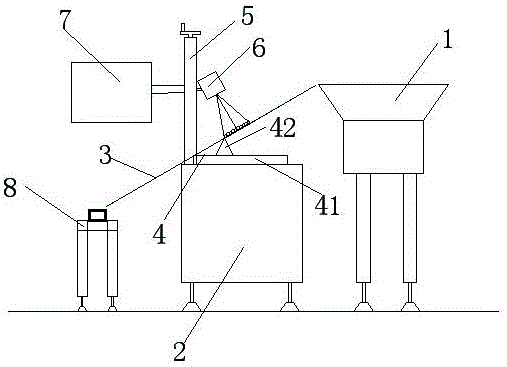

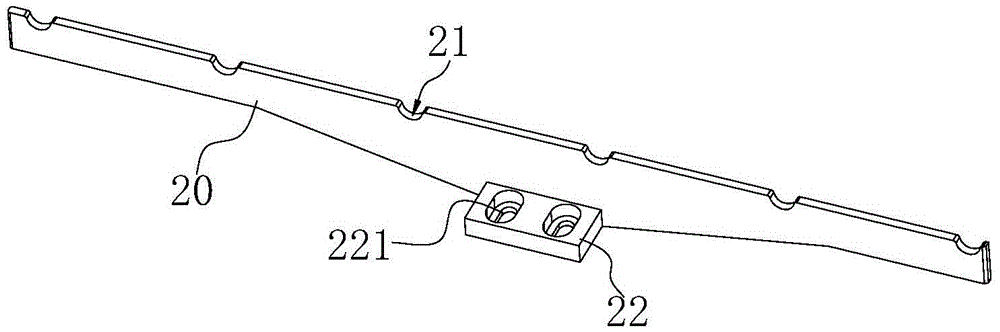

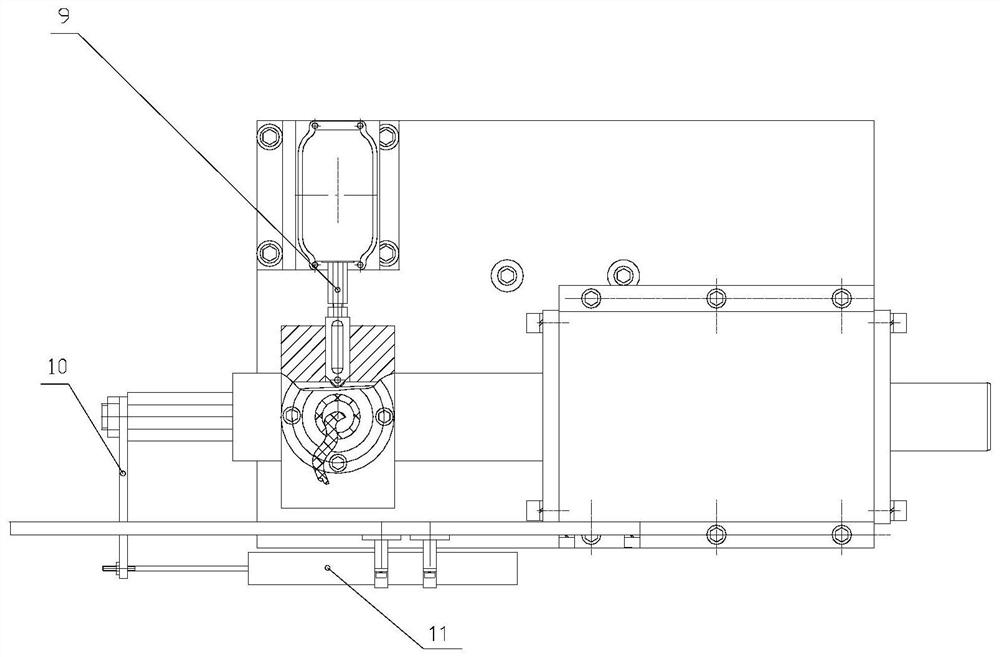

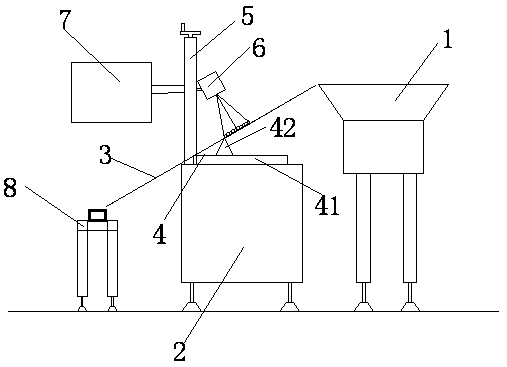

Automatic equipment and method for achieving high-speed laser marking and discharging packaging

ActiveCN105691769AMarking speed is fastImprove counting accuracyPackagingAutomatic test equipmentDisplay device

The invention discloses automatic equipment and method for achieving high-speed laser marking and discharging packaging. The automatic equipment comprises a vibration disc, a control cabinet, a discharging sliding rail, a height adjusting mechanism, a mounting column, a laser marking head, a displayer and a conveying mechanism. The discharging sliding rail is obliquely mounted above the control cabinet through the height adjusting mechanism. The mounting column is mounted on the control cabinet. The laser marking head and the displayer are mounted on the mounting column. The vibration disc is arranged at the high end of the discharging sliding rail. The conveying mechanism is mounted at the lower end of the discharging sliding rail. According to the automatic equipment for achieving high-speed laser marking and discharging packaging, automatic feeding, automatic marking, automatic counting and discharging packaging of nuts are combined together, meanwhile marking is conducted in a double-row manner, and high-speed marking can be achieved effectively.

Owner:EC PRECISION TECHJIANGSUCORP

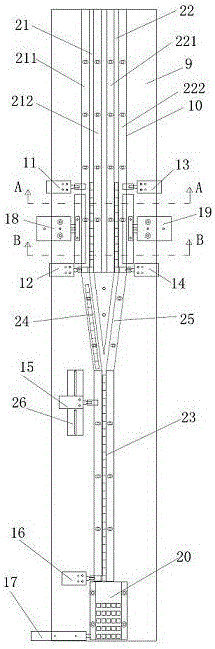

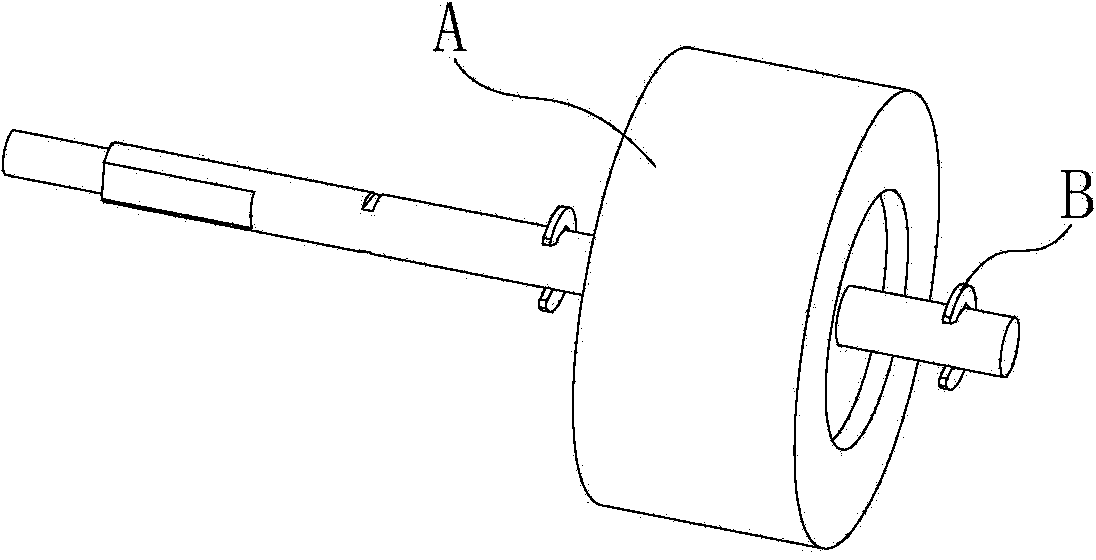

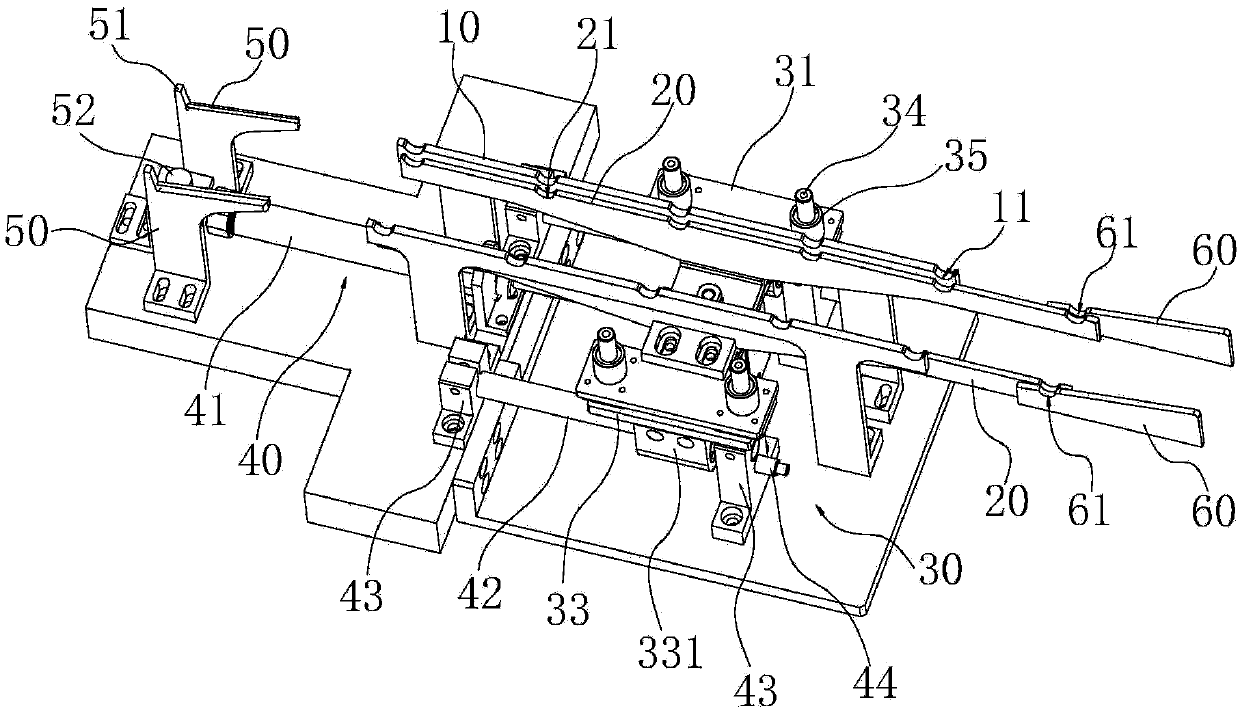

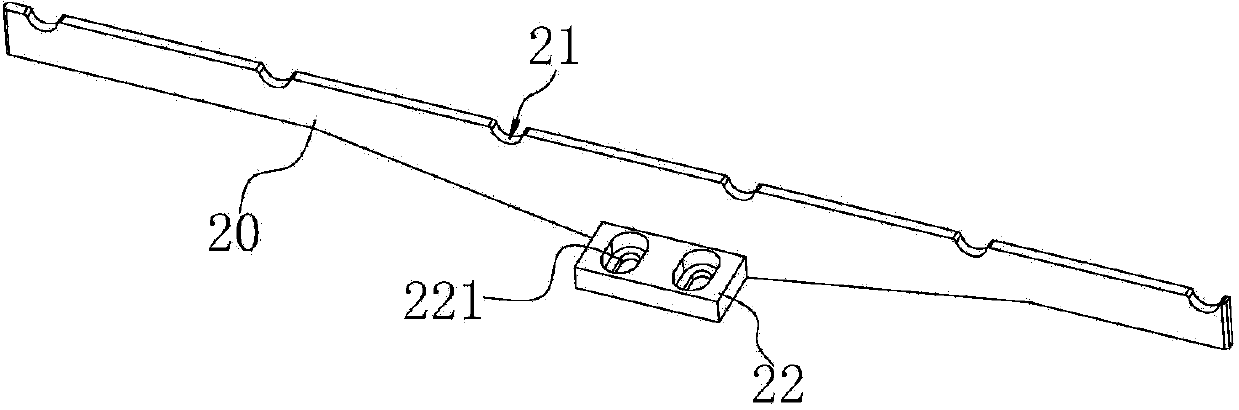

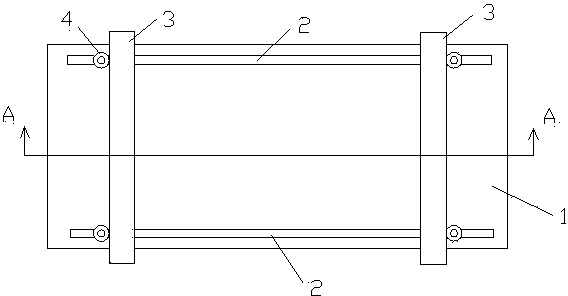

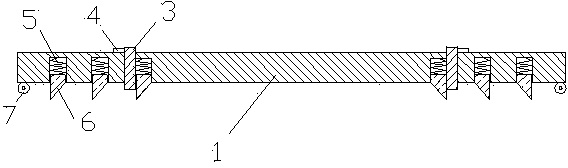

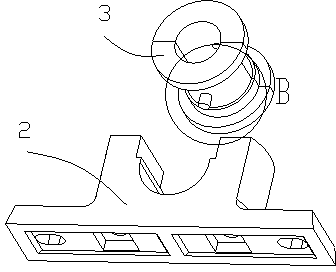

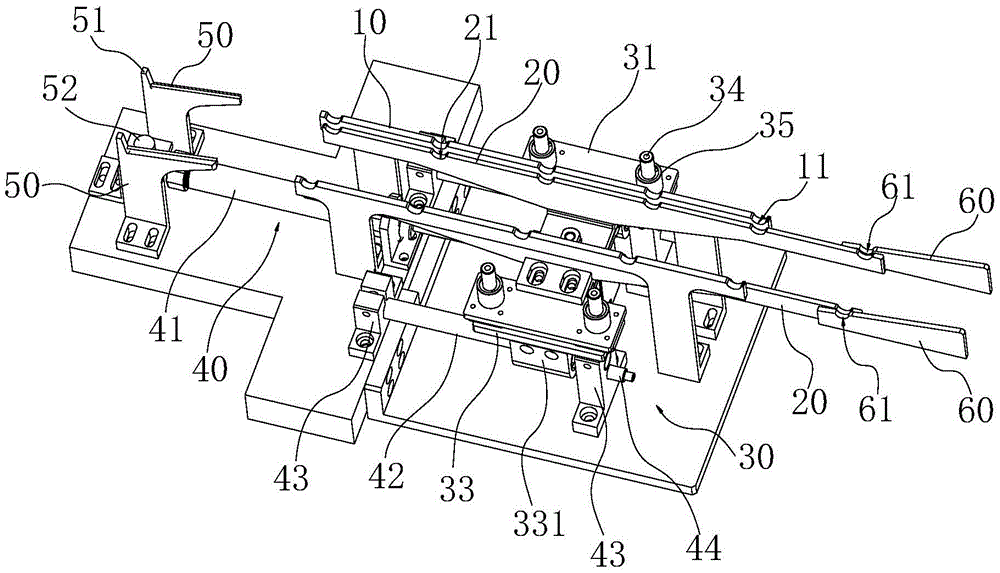

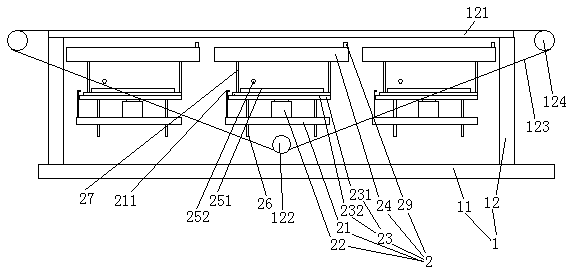

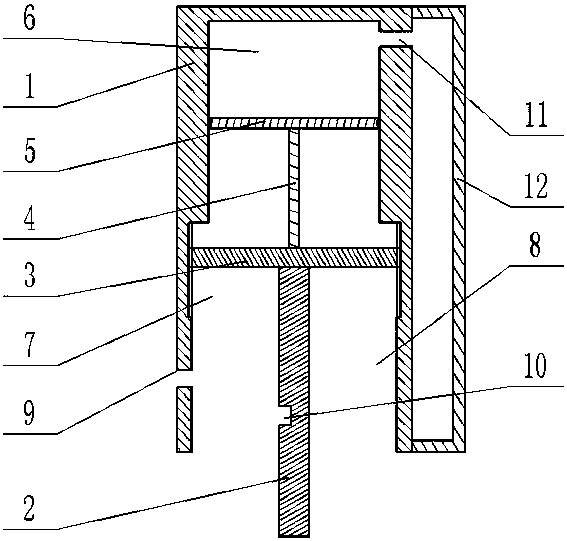

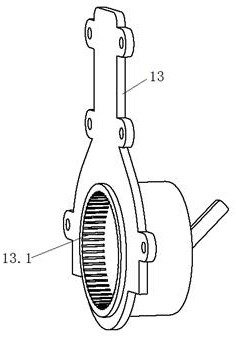

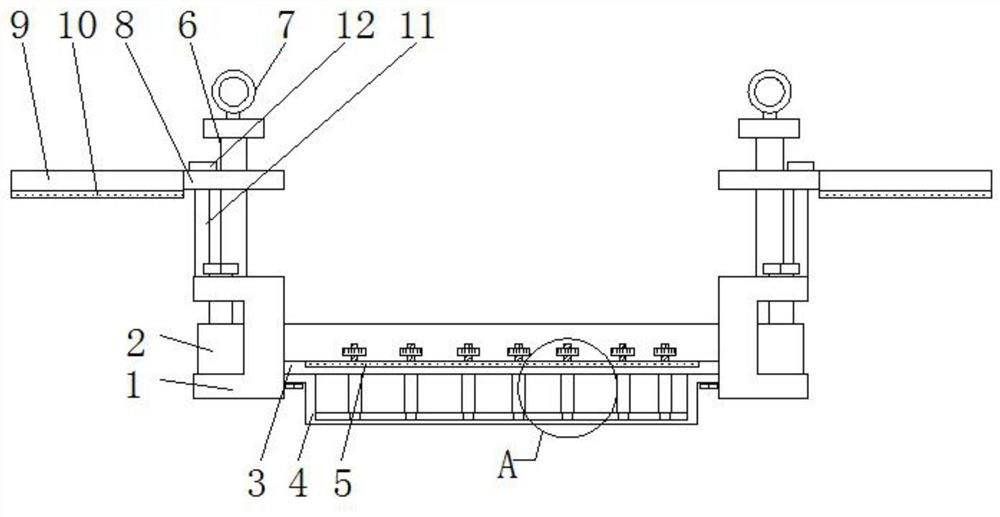

Rotor feeding device

ActiveCN103997166AWon't interfereEliminate the phenomenon of material jamManufacturing stator/rotor bodiesEngineeringSupport plane

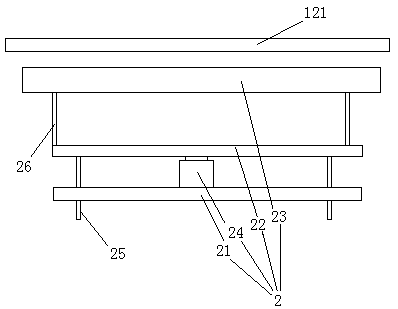

The invention belongs to the field of motor production, and particularly relates to a rotor feeding device. The rotor feeding device comprises two supporting frames arranged on a machine base in a spaced mode. The upper ends of the two supporting frames are provided with positioning grooves correspondingly. The motor feeding device further comprises two movable frames arranged in a spaced mode. The length direction of the movable frames is parallel to the length direction of the supporting frames, and the upper ends of the movable frames are provided with clamping grooves. The movable frames are arranged on a lifting unit. The lifting unit drives the movable frames to achieve two position states. According to one position state, when the movable frames are driven to ascend to the highest position, the bottoms of the clamping grooves are higher than the upper end faces of the supporting frames. According to the other position state, when the movable frames are driven to descend to the lowest position, the upper end faces of the movable frames are lower than the bottom of the positioning grooves of the supporting frames. The movable frames are further connected with a transportation unit. The transportation unit drives the movable frames to displace in the horizontal direction, and the positioning grooves and the clamping grooves are in the staggered position or the same position. A rotor is transported from one position to the other position by utilizing the clamping grooves and the positioning grooves, rotating shafts at the two ends of a rotor iron core are accurately positioned, the phenomenon of material clamping in the rotor transportation process is fundamentally and completely eradicated, and it is ensured that the rotor can be normally transported.

Owner:合肥凯邦电机有限公司

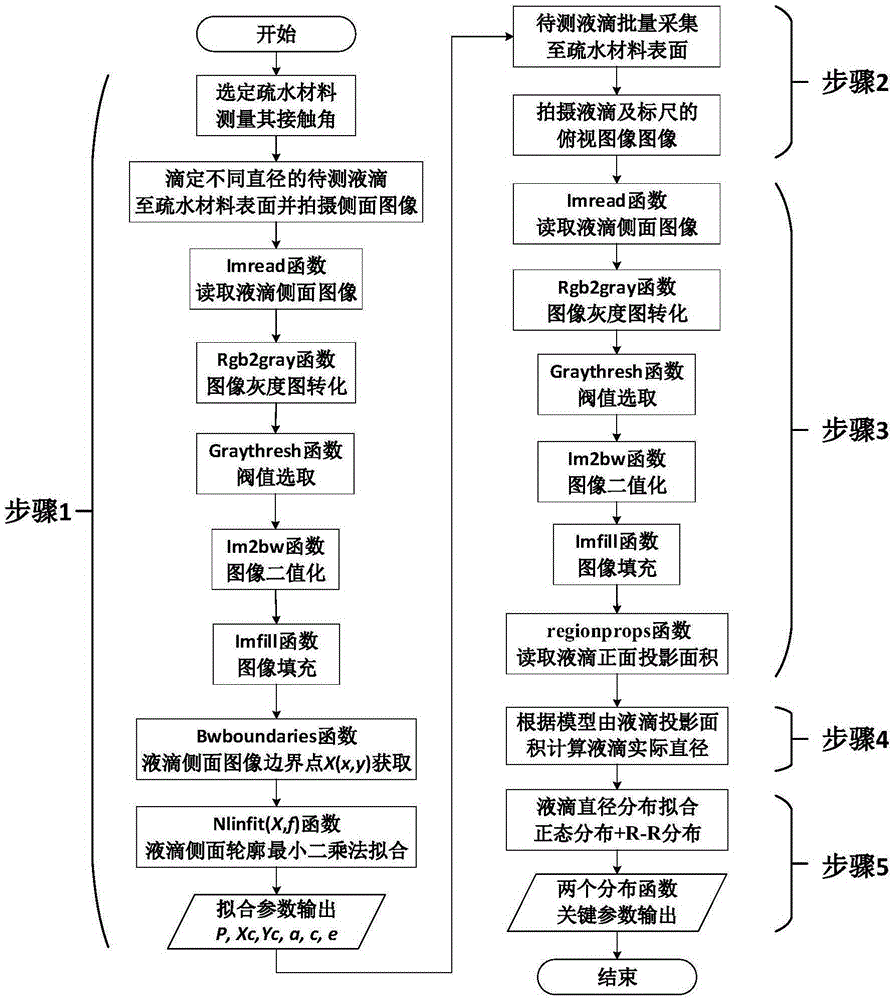

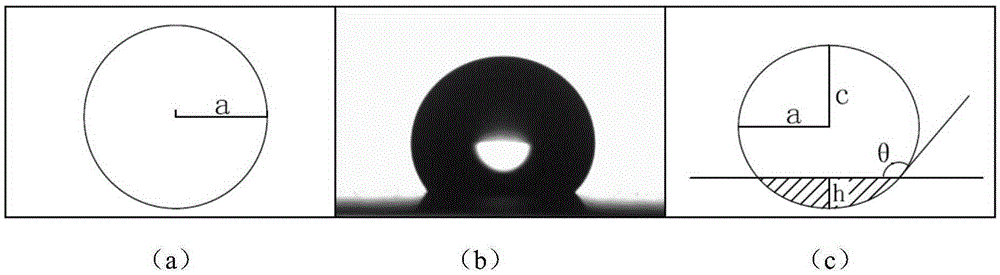

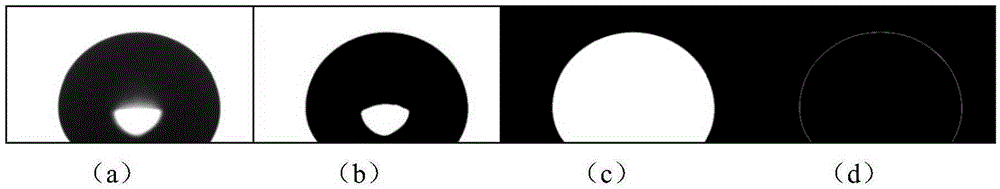

Liquid drop diameter distribution measurement method based on hydrophobic material

ActiveCN105372165AImprove adaptabilityImprove adhesionParticle size analysisImaging processingMeasurement cost

The invention discloses a liquid drop diameter distribution measurement method based on a hydrophobic material. The measurement process comprises steps as follows: (1), characteristic representation of a single liquid drop on the surface of the hydrophobic material; (2), acquisition of lot-sizing liquid drops on the hydrophobic material; (3), image processing of the lot-sizing liquid drops; (4), model calculation of actual diameters of the liquid drops; (5), fitting of liquid distribution characteristics. According to the method, the shape of each single liquid drop on the surface of the hydrophobic material is represented by means of the characteristic that the shape of the liquid drops can be maintained on the surface of the hydrophobic material, accordingly, lot-sizing and automatic processing of the liquid drops is realized, and a liquid drop distribution function is obtained directly. Compared with a traditional sampling measurement method, the method has higher adaptability to the liquid drops with different characteristics, and lot-sizing processing capacity and automatic processing capacity are remarkably improved; compared with an optical measurement method, the method is free from influence of non-spherical liquid drops in the air, the measurement cost is remarkably reduced, and in-site measurement is easy to realize.

Owner:SOUTHEAST UNIV

Building steel pipe moving and transporting device

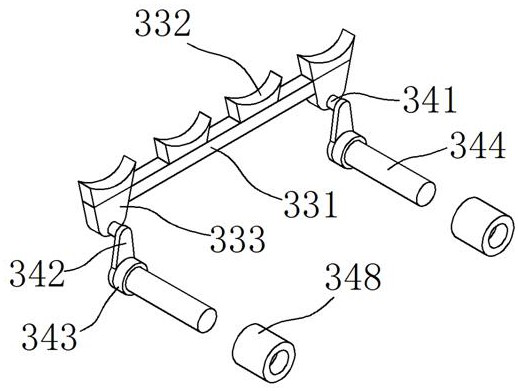

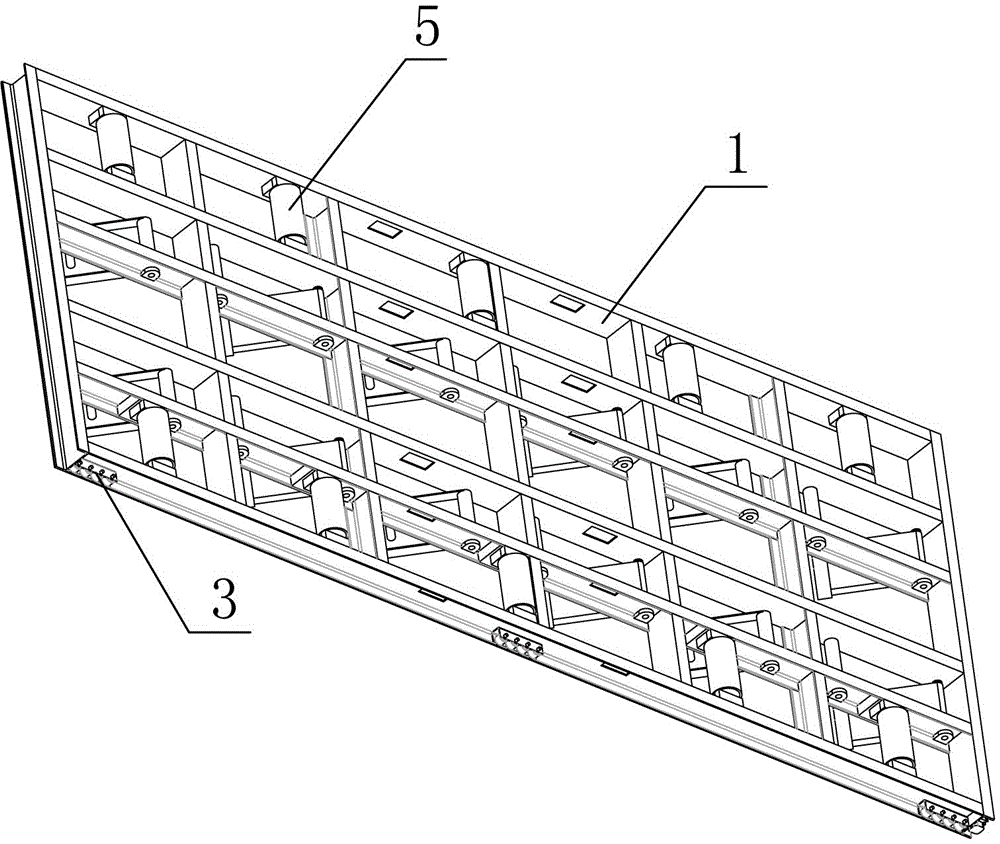

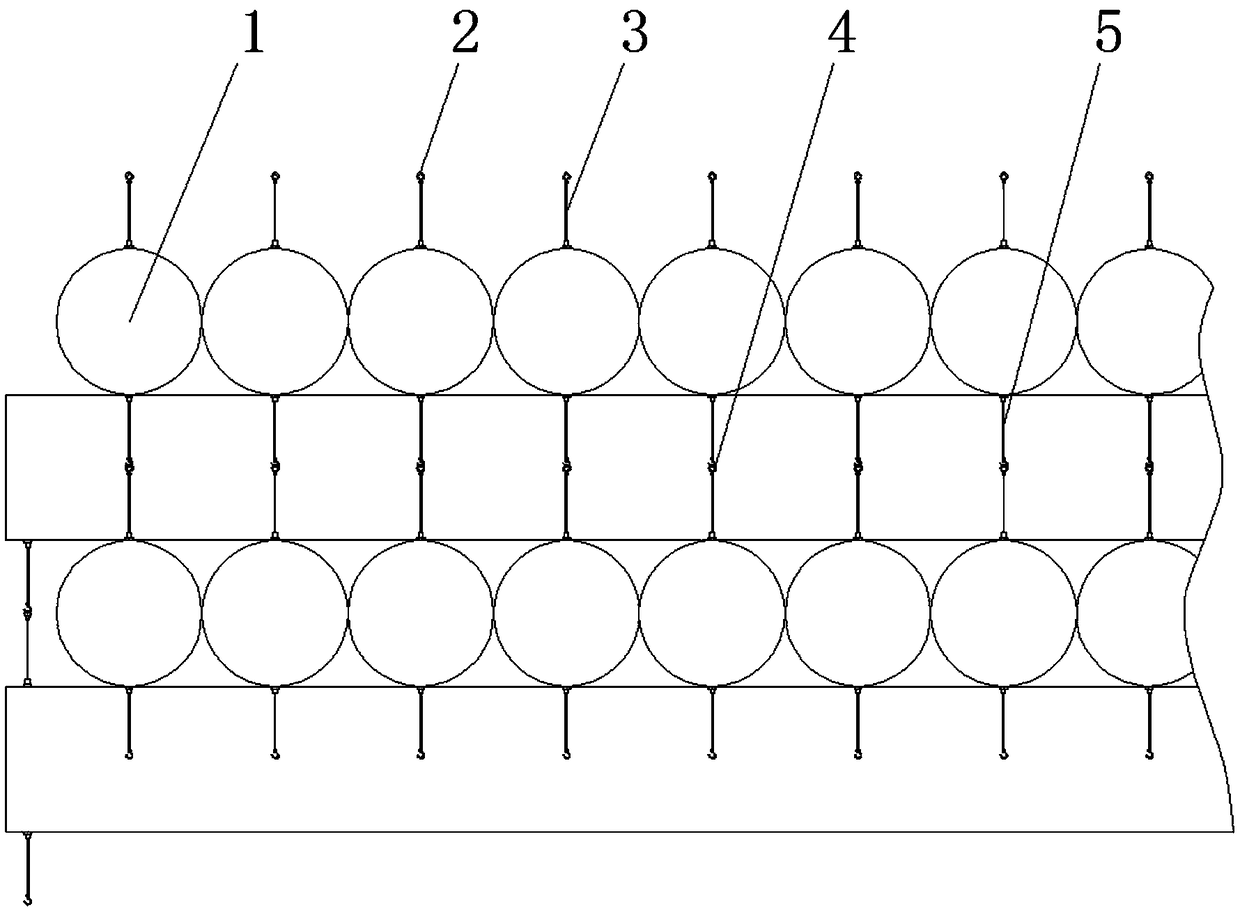

InactiveCN111731830AEasy to handleNo scrollingConveyorsConveyor partsArchitectural engineeringStructural engineering

The invention provides a building steel pipe moving and transporting device. The building steel pipe moving and transporting device comprises a first inclined slide way; a translation structure is arranged on one side of the first inclined slide way, the translation structure comprises two symmetrically-arranged supporting plates, a plurality of blocking toothed plates are evenly arranged at the tops of the two supporting plates, and a translation unit is arranged between the two supporting plates. The building steel pipe moving and transporting device is reasonable in structural design, steelpipes sliding down from the first inclined sliding way are conveyed one by one at equal intervals through the translation unit by means of the translation structure, follow-up steel pipe treatment isfacilitated, meanwhile, the steel pipes cannot roll in the conveying process, and safety accidents are reduced.

Owner:芜湖天达重工有限公司

Wheel cart

InactiveCN103723173ANo scrollingNo slipping phenomenonHand carts with multiple axesEngineeringElectrical and Electronics engineering

The invention discloses a wheel cart comprising a carrying table top. Wheels are arranged at four corners of the lower surface of the carrying table top. Grooves are formed in the upper side and the lower side of the carrying table top respectively. Two positioning bolts are arranged in each groove. Two limiting plates are sleeved on the carrying table top between the two positioning bolts, and can move along the length direction of the carrying table top. The limiting plates are arranged on the carrying table top of the cart and are limited by the positioning bolts and limiting blocks, and the positions of the limiting plates can be adjusted according to needs, so that rolling and slipping of wheels on the carrying table top are avoided.

Owner:WUJIANG WALLMATE DECORATION MATERIALS

Support arm moving and grinding device based on overhead working truck manufacturing

ActiveCN113635160AIncrease elasticityNo scrollingGrinding work supportsPlane surface grinding machinesGear grindingTruck

The invention provides a support arm moving and grinding device based on overhead working truck manufacturing, relates to the field of grinding, and aims to solve the problems that when different grinding requirements are met, a grinding mechanism is not convenient to mount and maintain, a multi-gear grinding force adjusting structure is lacked, and when slight grinding is needed, a heavy block is not convenient to add for stress grinding. The support arm moving and grinding device comprises a moving part, the bottom of the moving part is of an arc-shaped structure, a threaded hole is formed in the bottom of the moving part, a moving table comprises an adjusting plate, two round holes are formed in the adjusting plate, guide rods are inserted into the round holes, the bottom of the adjusting plate makes contact with the top ends of springs on the outer sides of the guide rods, and the adjusting plate is inserted into limiting grooves. When the grinding force needs to be adjusted, the inner end of the adjusting plate can be controlled to be inserted into the limiting grooves in different positions, so that the springs are compressed to different degrees, the moving table is pulled through different force, and thus the force of the moving table can be adjusted for grinding.

Owner:南通炫昱实业有限公司

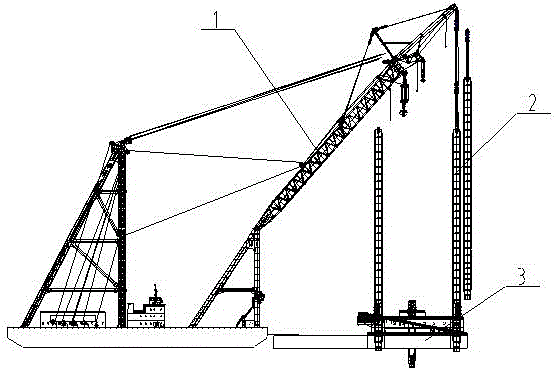

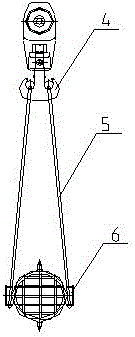

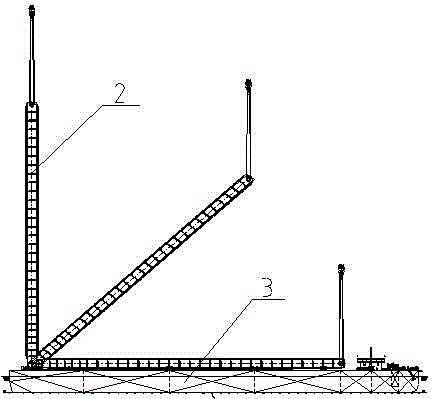

Pile leg pulling and rolling-over process for heavy lifting mechanism

The invention relates to a pile leg pulling and rolling-over process for a heavy lifting mechanism. The pile pulling process for a pile leg comprises the following steps of preparation work before hoisting, specifically, a floating crane is arranged, a locking device is released, and an upper opening encoder is detached; then a lifting system is disconnected from a power supply, and a brake is turned on; and a rolling-over tool and a holding tool are arranged in place; pile pulling, specifically, the pile leg is lifted to a limiting altitude and held through the floating crane, the pile leg is lifted upwards continuously by utilization of a lifting device and protected by the floating crane upwards synchronously, and then the pile leg pulling work is finished; and pile leg rolling-over, specifically, after the pile leg is pulled out slowly, a lower opening of the pile leg is slowly placed onto the rolling-over tool, and the pile leg is rolled over and then detached from a hook after being laid onto the holding tool. The pile leg pulling and rolling-over process for the heavy lifting mechanism has the advantages that pile leg pulling operation can be finished by only utilizing the single floating crane, and only a few devices are required; the rolling-over tool is adopted as the rolling-over tool for the pile leg, and pile leg rolling-over operation can be finished through the single floating crane and the single rolling-over tool only; and the holding tool is arranged, so that stability when the pile leg is arranged horizontally after being rolled over is well guaranteed.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

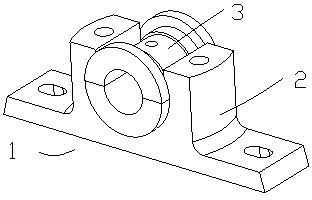

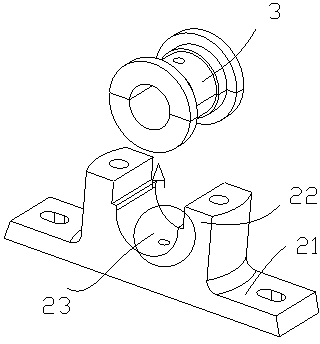

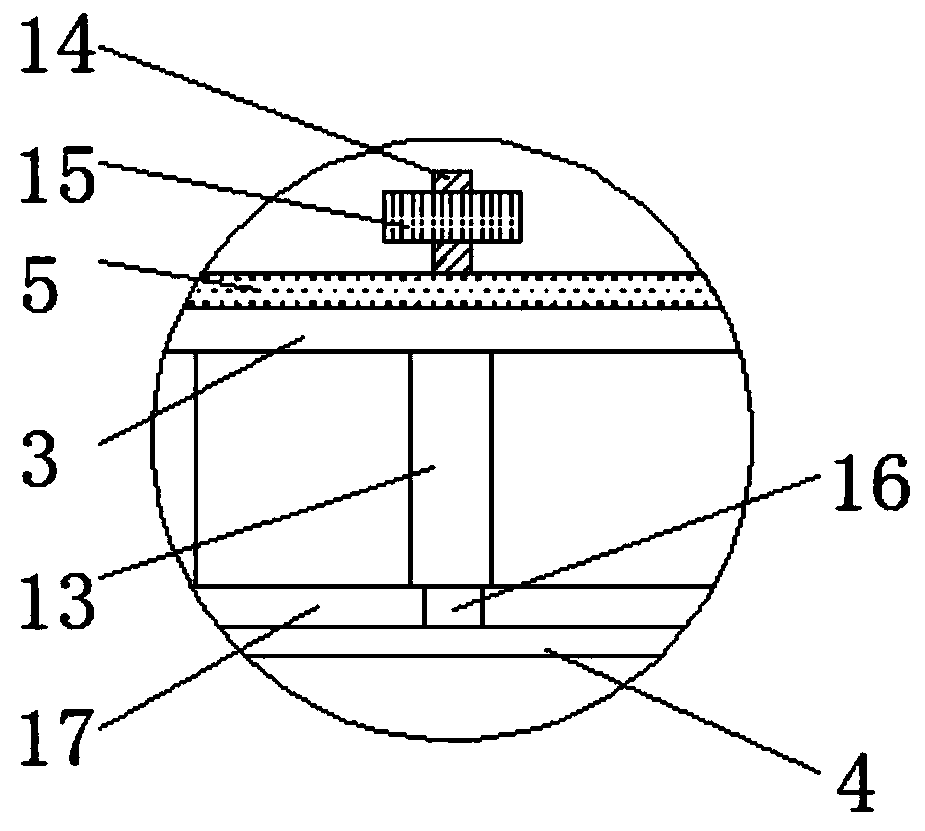

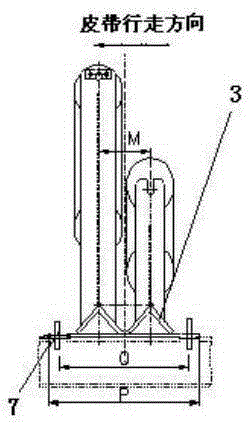

Anti-disengaging mandrel roller fixing device for caterpillar track conveyer

InactiveCN103964131AImprove stabilityImprove ride comfort and reliabilityConveyorsManufacturing engineeringDowel

The invention discloses an anti-disengaging mandrel roller fixing device for a caterpillar track conveyer. The anti-disengaging mandrel roller fixing device for the caterpillar track conveyer comprises a base and a support roller. The support roller can be separately connected with the base. According to the anti-disengaging mandrel roller fixing device for the caterpillar track conveyer, a positioning through hole in the middle of a fixed arc face and a positioning dowel at the side wall of a roller main body are adopted, even through the support roller is worn, the whole support roller will not roll, stability of the driving roller is improved greatly, and harshness and reliability of a rubber conveying belt of the caterpillar track conveyer are improved effectively.

Owner:于浩

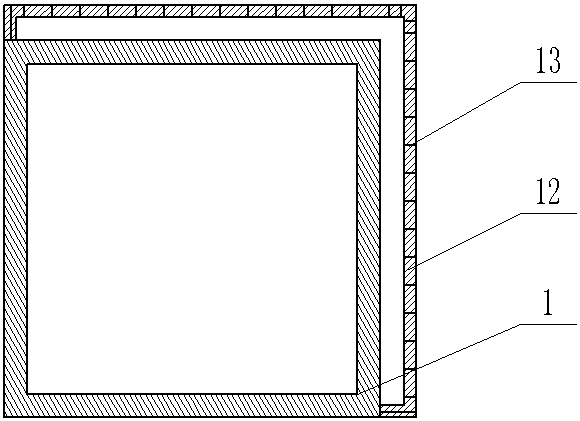

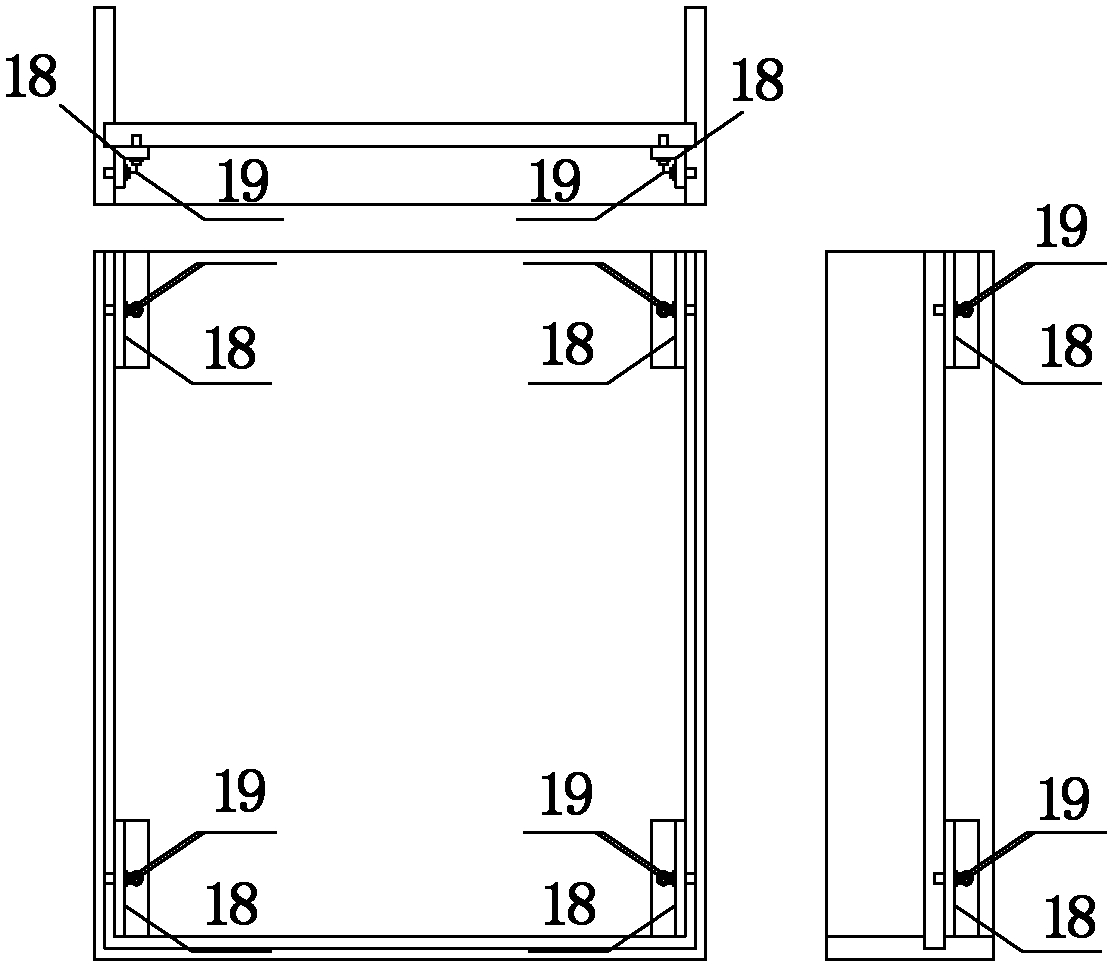

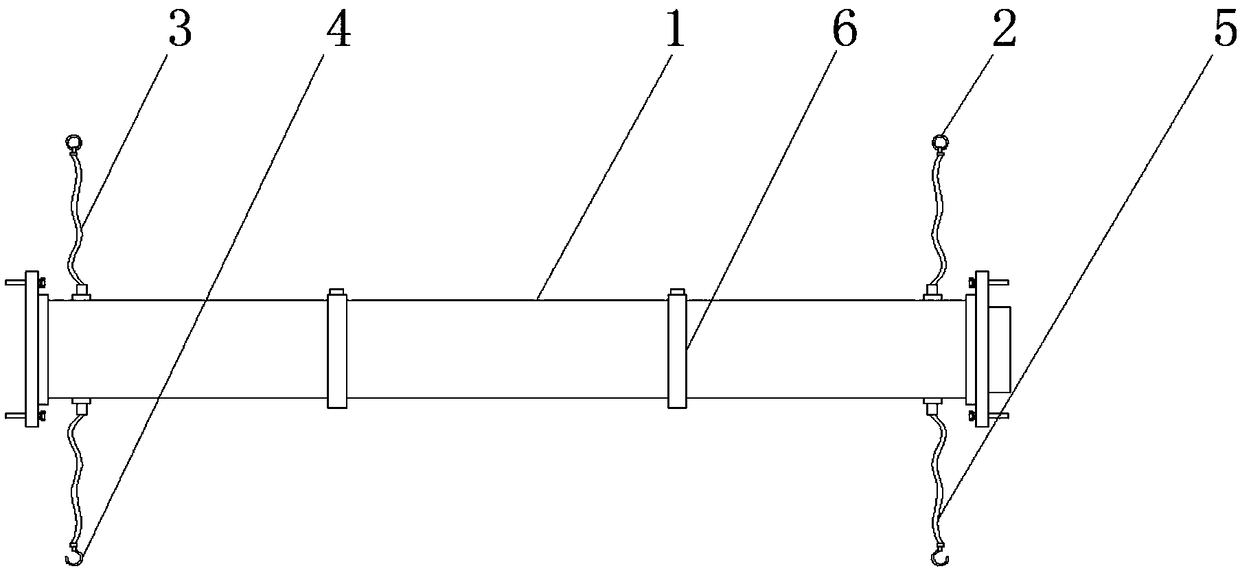

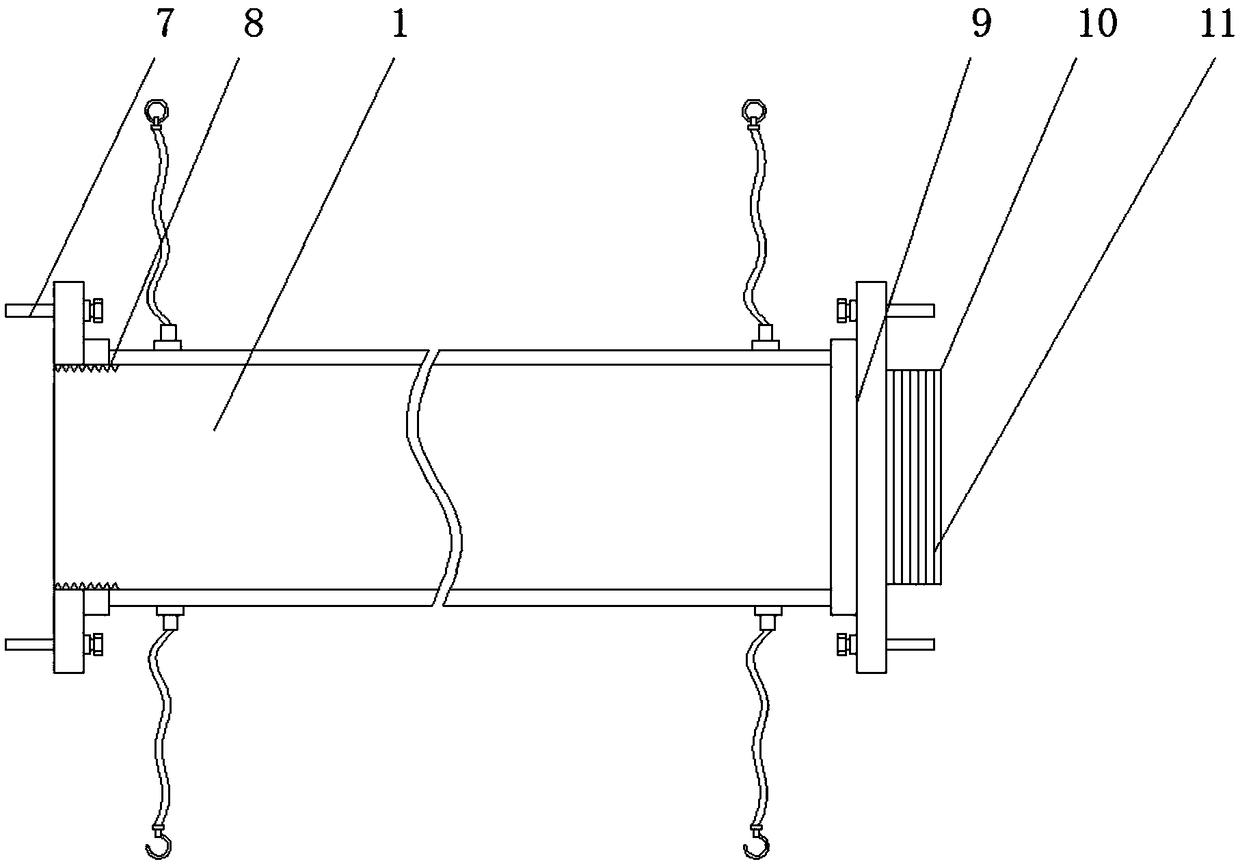

Novel assembly type hanging bracket

ActiveCN111377354ANo scrollingNo slipBuilding material handlingLoad-engaging elementsStructural engineeringMechanical engineering

The invention discloses a novel assembly type hanging bracket. By arranging an underframe, a plurality of partition plates are movably arranged in the underframe, the underframe can be used for hoisting small-sized hoisting materials, and the hoisting materials are fixed through the pressing of the partition plates, so that the situation that the hoisting materials slide in the hoisting process isprevented. According to the novel assembly type hanging bracket, due to the fact that pressing plates are arranged on movable sleeves of vertical rods and large-size materials hung on fixing plates can be pressed through downward extrusion of the pressing plates, the hoisting safety of the hanging bracket is higher, and the hoisting efficiency is also improved. The novel assembly type hanging bracket is a special hanging bracket for an assembly type building small-sized component, and meanwhile, the hoisting requirement of larger components can be considered. The hanging bracket has the characteristics of being simple in structure, simple and convenient to operate, wide in application range, safe and reliable.

Owner:CHINA FIRST METALLURGICAL GROUP

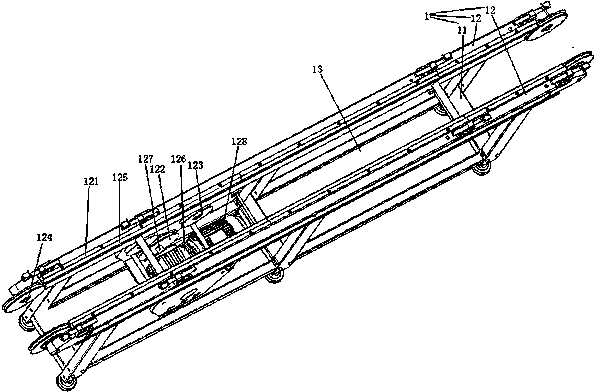

Round-belt side-supporting type optical fiber disc delivery mechanism and optical fiber disc delivery method

The invention relates to a round-belt side-supporting type optical fiber disc delivery mechanism. The mechanism comprises a rack, the rack comprises two side frames which are distributed in the longitudinal direction, the side frames are provided with belt supporting holding cross beams, driving belt wheels located below the belt supporting holding cross beams, delivery motors used for driving thedriving belt wheel to rotate, round conveying belts and driven belt wheels which are located at the two ends of the belt supporting holding beams, the round conveying belts are connected with the driven belt wheels and the driving belt wheels, the round conveying belts are supported and held by the belt supporting holding cross beams, an optical fiber conveying groove is formed in the part between the two side frames, belt limiting grooves which extend in the extending directions of cross supporting beams are formed in the cross supporting beams, and the round conveying belts are accommodatedin the belt limiting grooves and are protruded out of the belt limiting grooves. The optical fiber disc delivery mechanism has the advantages that rolling can be prevented in the optical fiber disc process without needing supporting discs, and the problems of the increasing of the working intensity caused by the prevention of the rotation of the optical fiber discs when the optical fiber discs are contained in the supporting discs to be delivered of existing optical fiber disc delivery mechanisms and the need of adding spatial storage supporting discs are solved.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

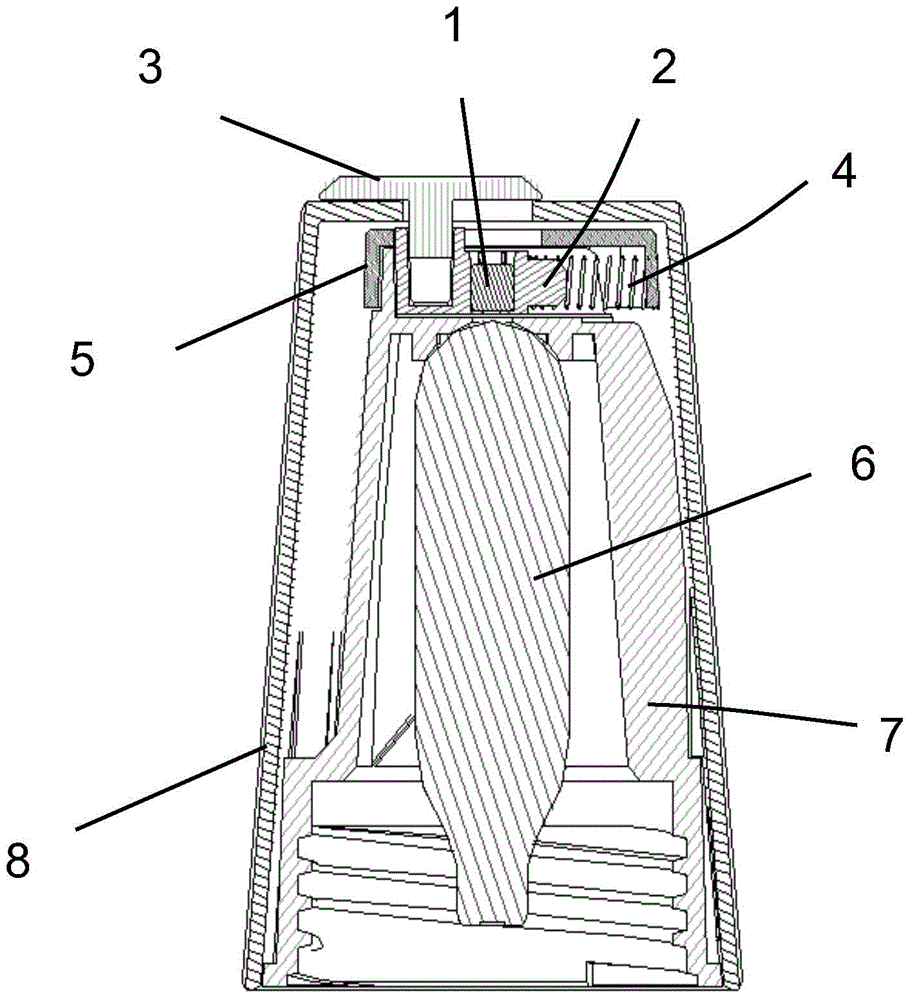

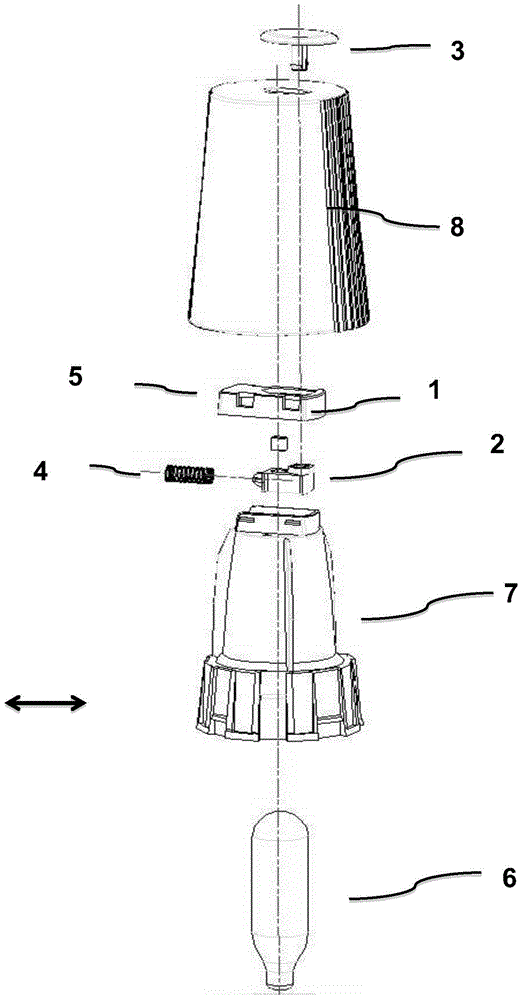

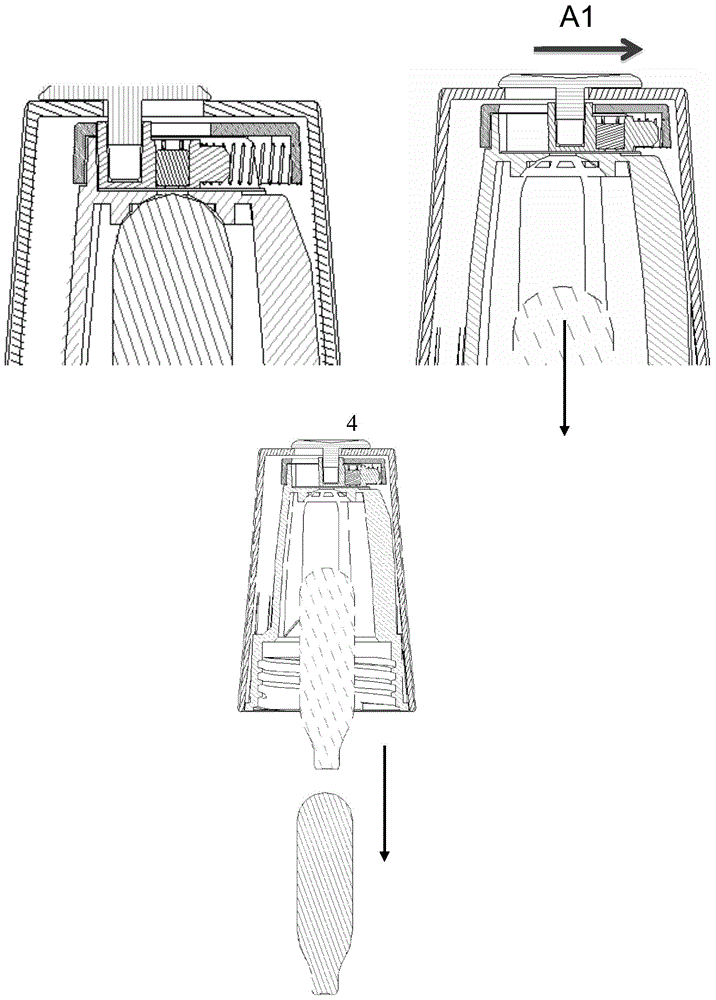

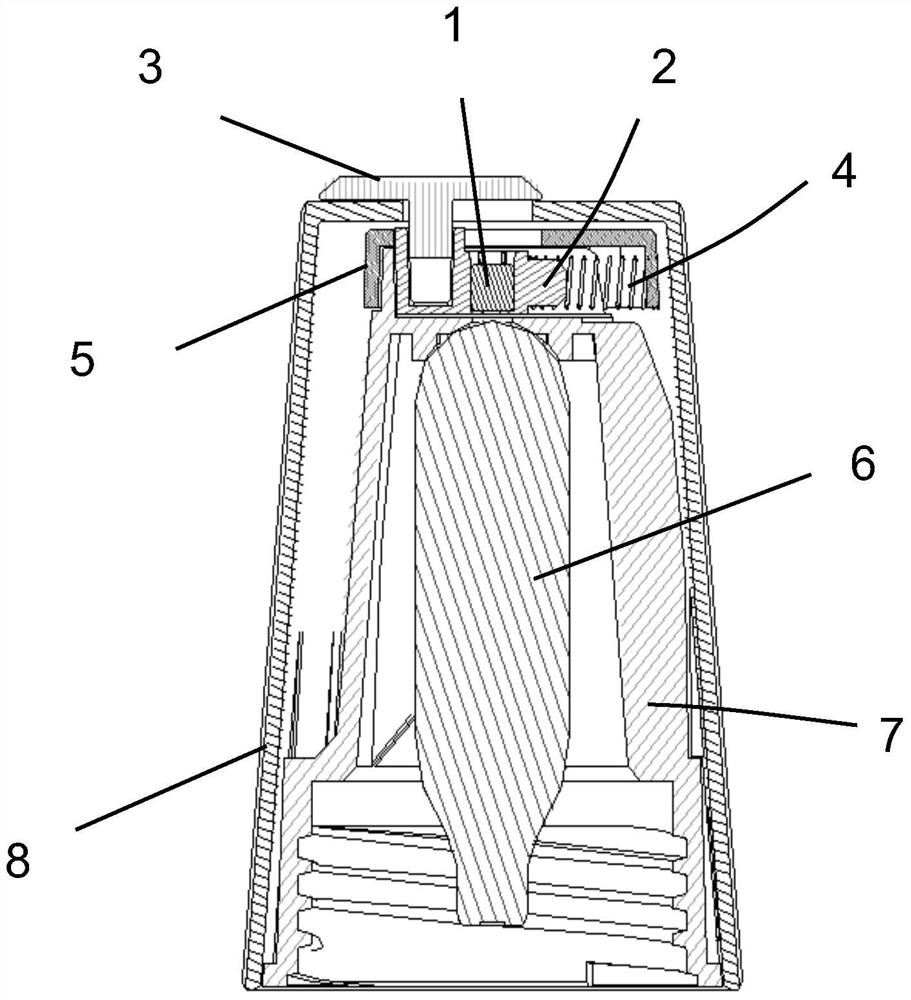

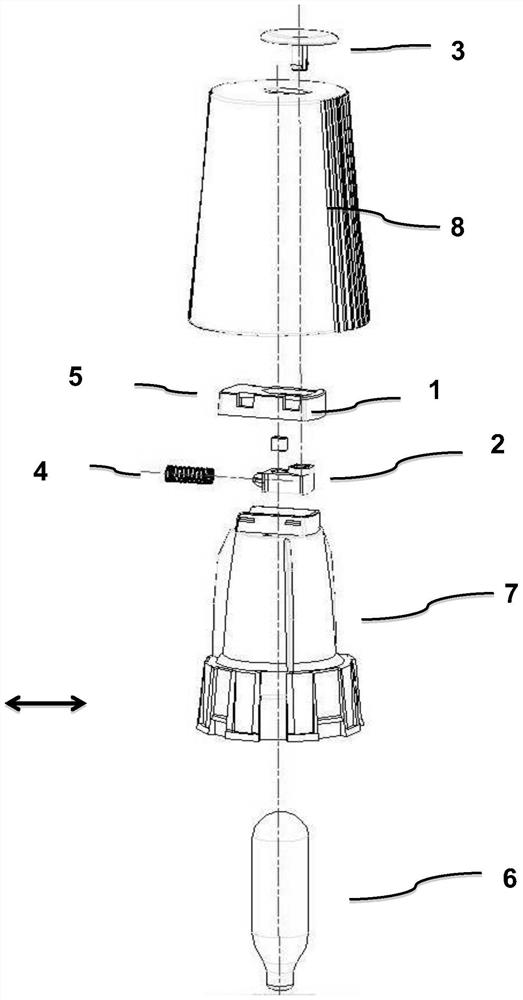

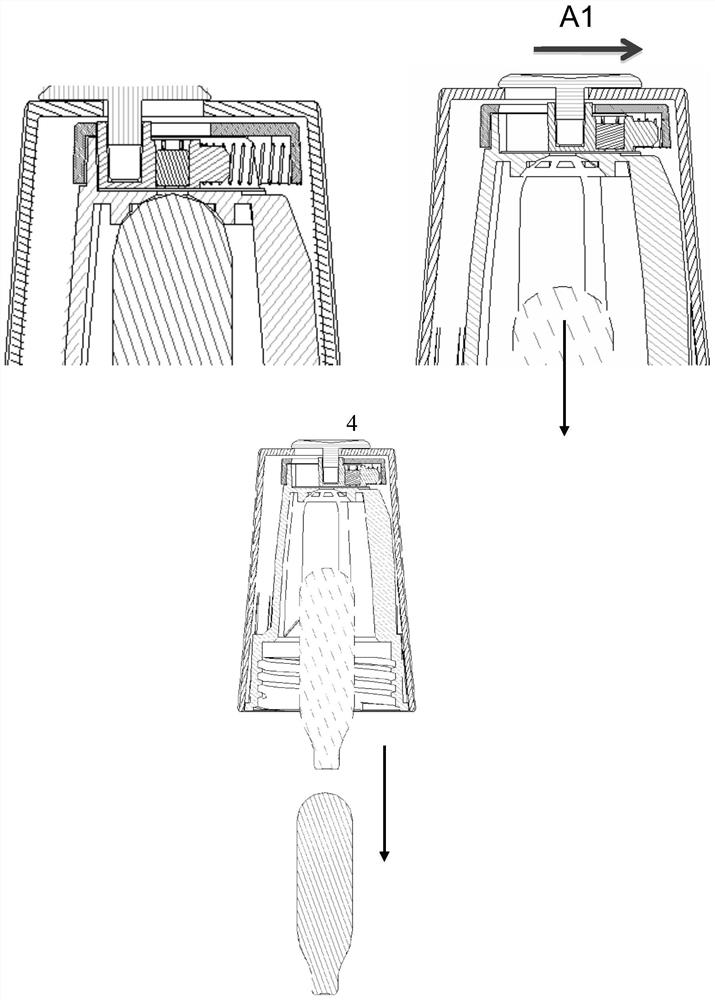

Magnetic inflation bottle holding device for aerated water machine and aerated water machine

The invention relates to a magnetic inflation bottle holding device for an aerated water machine and the aerated water machine. The magnetic inflation bottle holding device holds and releases a CO2 inflation bottle through magnetic force, makes the CO2 inflation bottle conveniently replaced, and is easy to operate and high in replacement efficiency. A safety mechanism of the aerated water machine comprises two or more pressure releasing channels. Pressure releasing is rapid and balanced, safety is higher, the pressure releasing threshold value is adjusted by changing the elasticity of a silica gel sleeve and the position and aperture of a releasing hole, the structure is simple, and control is easy. According to a pressurized bottle of the aerated water machine, the outer column surface of a bottle cover and a bottle body has a longitudinal section plane, so screwing and holding are easy, the design is economical, and the pressurized bottle is not prone to rolling when placed transversely. Meanwhile, due to the large bottle mouth diameter, filling-in and pouring-out are easier.

Owner:真上康国际有限公司

Rotor Feeder

ActiveCN103997166BWon't interfereEliminate the phenomenon of material jamManufacturing stator/rotor bodiesEngineeringSupport plane

The invention belongs to the field of motor production, and particularly relates to a rotor feeding device. The rotor feeding device comprises two supporting frames arranged on a machine base in a spaced mode. The upper ends of the two supporting frames are provided with positioning grooves correspondingly. The motor feeding device further comprises two movable frames arranged in a spaced mode. The length direction of the movable frames is parallel to the length direction of the supporting frames, and the upper ends of the movable frames are provided with clamping grooves. The movable frames are arranged on a lifting unit. The lifting unit drives the movable frames to achieve two position states. According to one position state, when the movable frames are driven to ascend to the highest position, the bottoms of the clamping grooves are higher than the upper end faces of the supporting frames. According to the other position state, when the movable frames are driven to descend to the lowest position, the upper end faces of the movable frames are lower than the bottom of the positioning grooves of the supporting frames. The movable frames are further connected with a transportation unit. The transportation unit drives the movable frames to displace in the horizontal direction, and the positioning grooves and the clamping grooves are in the staggered position or the same position. A rotor is transported from one position to the other position by utilizing the clamping grooves and the positioning grooves, rotating shafts at the two ends of a rotor iron core are accurately positioned, the phenomenon of material clamping in the rotor transportation process is fundamentally and completely eradicated, and it is ensured that the rotor can be normally transported.

Owner:合肥凯邦电机有限公司

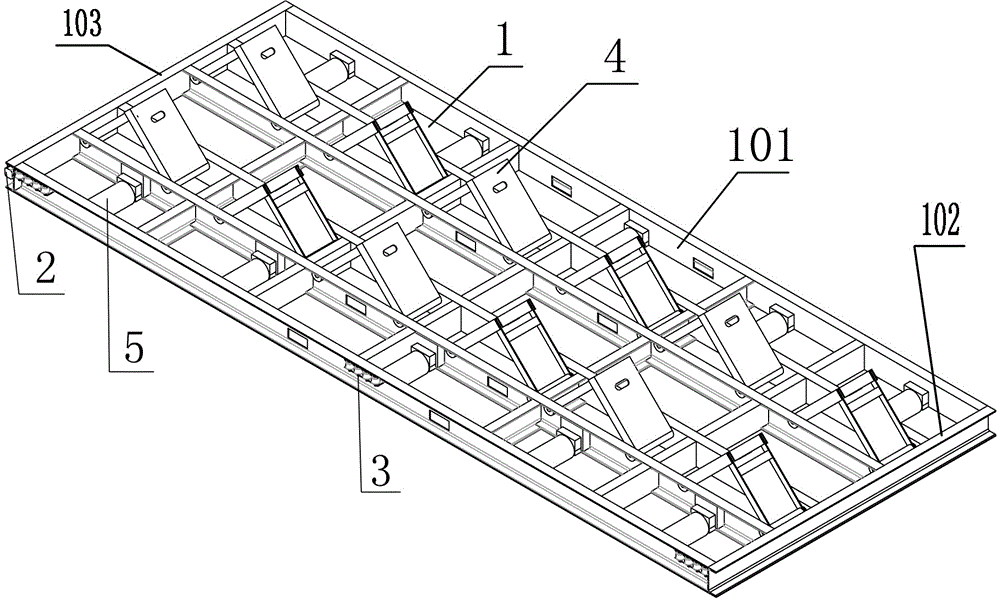

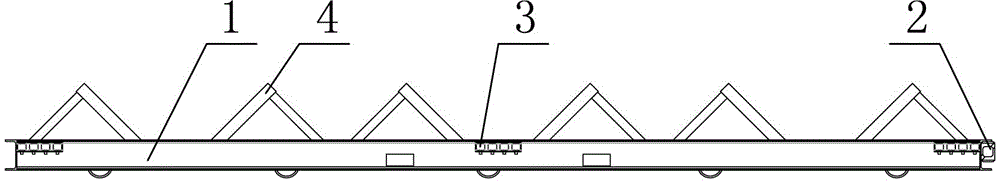

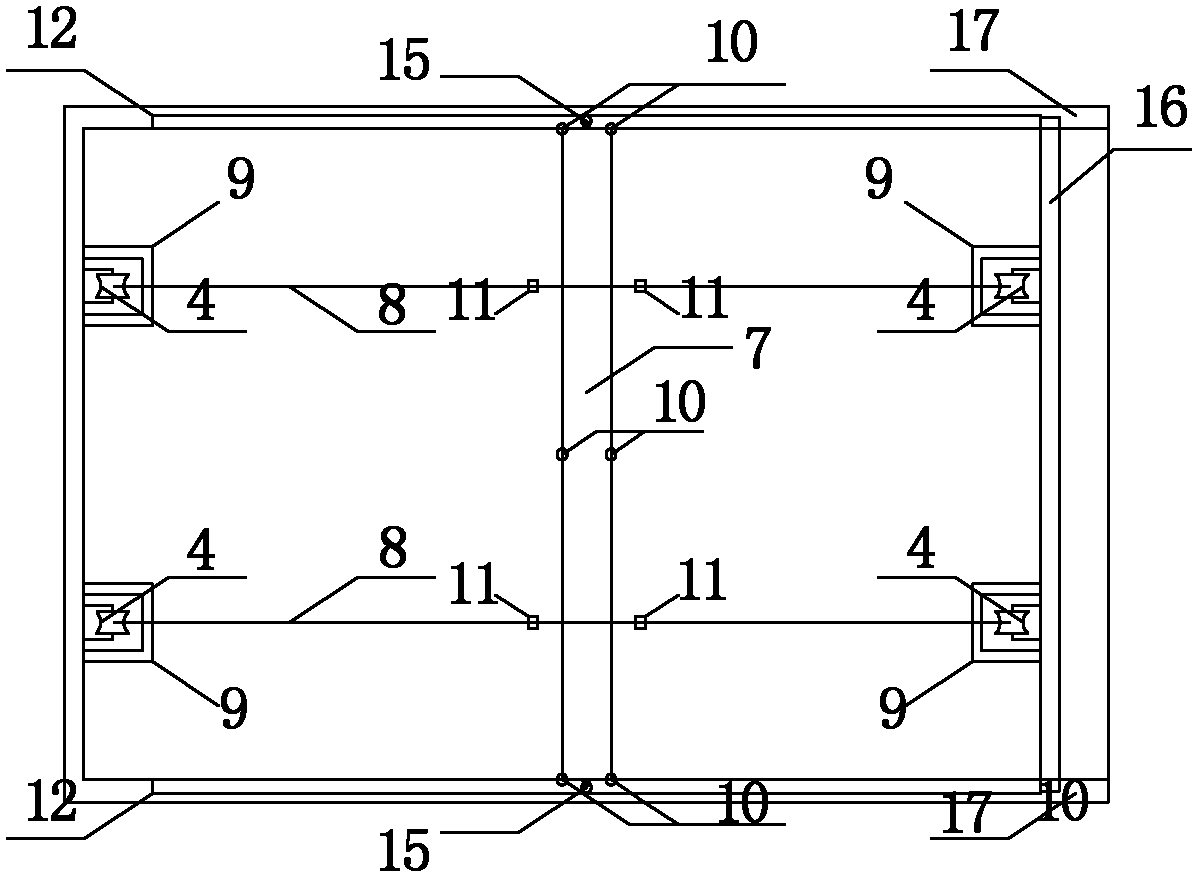

Multifunctional mobile tray with locking mechanism

The present invention relates to the field of transport equipment for containers, in particular to a multifunctional mobile pallet with a locking device, comprising a chassis (1) and a cargo fixing device (4), the two sides (101) of the chassis (1) and the rear edge ( 103) The two included angle parts are provided with a rear edge locking device (2), and the pallet can be reliably fixed in the container through the rear edge locking device (2); the cargo fixing device (4) consists of two Or four support surfaces, each support surface is composed of two rotatable support beams (401), the support beams (401) are connected with the longitudinal channel steel of the chassis (1) through pin shafts (402), and the support beams (401 ) The movable ends are locked with each other through the card slot to form a stable triangular support surface, so as to ensure that the round goods placed on the pallet will not slip. When loading ordinary cargo, the movable ends of the support beam (401) are unlocked and locked to each other, and are stored under the upper plane of the chassis (1) through the rotation of the pin shaft (402), which is simple and convenient to operate.

Owner:SHANGHAI YUANTAIDA RAIL EQUIP

Barrel capable of being placed reversely and stably

The invention relates to a barrel capable of being placed reversely and stably. The barrel comprises a barrel body and supporting plates; the supporting plates are hinged to the side wall of the barrel body, supporting strips are arranged between the barrel body and the supporting plates; the supporting plates and the supporting strips are of arc-shaped structures being attached to the side wall of the barrel body; the supporting strips are hinged to the side wall of the barrel body, clamping grooves are formed in the supporting plates, when the supporting plates are turned over to be opened and used for supporting the barrel body, one free ends, which are not hinged, of the supporting strips are clamped into the clamping grooves to fix the supporting plates; or, the supporting strips are hinged to the supporting plates, clamping grooves are formed in the side wall of the barrel body, when the supporting plates are turned over to be opened and used for supporting the barrel body, one free ends, which are not hinged, of the supporting strips are clamped into the clamping grooves to fix the supporting plates. The barrel can be stably stored on the plane or a slope and does not roll.

Owner:TIANJIN PROMISE PLASTICS

Round belt side-support type optical fiber disc conveying mechanism capable of rectifying and optical fiber disc conveying method

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

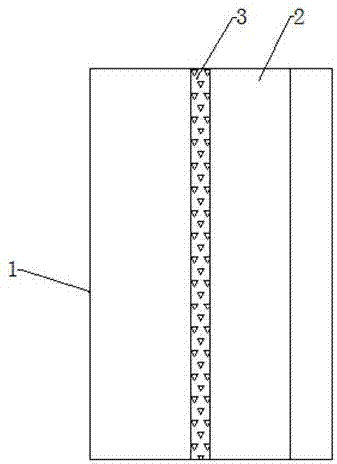

Deviation-correctable flat-belt side-supporting optical fiber tray conveying mechanism and optical fiber tray conveying method

The invention relates to a flat-belt side-supported optical fiber reel conveying mechanism capable of correcting deflection, which includes a frame, and the frame includes two side frames distributed along the longitudinal direction. The belt includes a driving conveying roller, a driven conveying roller, a conveying motor that drives the driving conveying roller to rotate, and a flat belt with a rectangular cross section arranged on the driving conveying roller and the driven conveying roller. The flat belt has a circular structure, so An inverted "eight" shaped optical fiber tray delivery trough is formed between the conveyor belts on the two side frames, and several optical fiber tray deviation correction mechanisms distributed along the transverse direction are arranged in the optical fiber tray delivery trough. The invention provides a flat-belt side-mounted optical fiber reel conveying mechanism that can prevent the optical fiber reel from rolling without a tray, and solves the problem that the existing optical fiber reel conveying mechanism transports the optical fiber reel through the tray. Prevent the increased workload caused by the rotation of the fiber optic tray and give the need to increase the space to store the tray.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

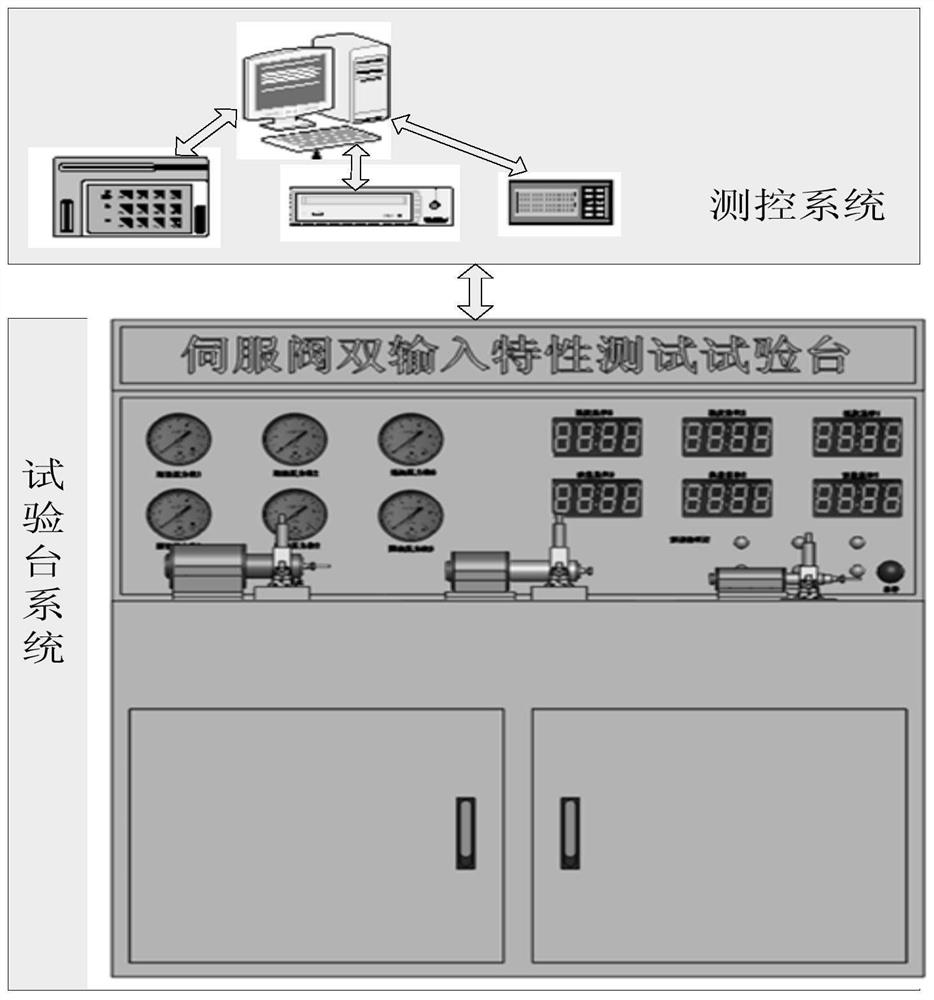

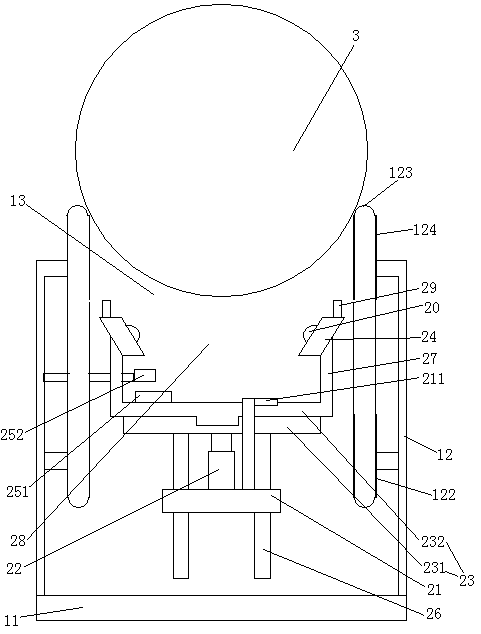

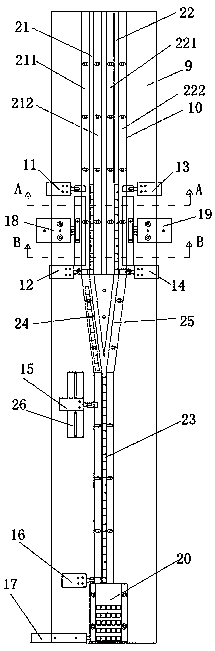

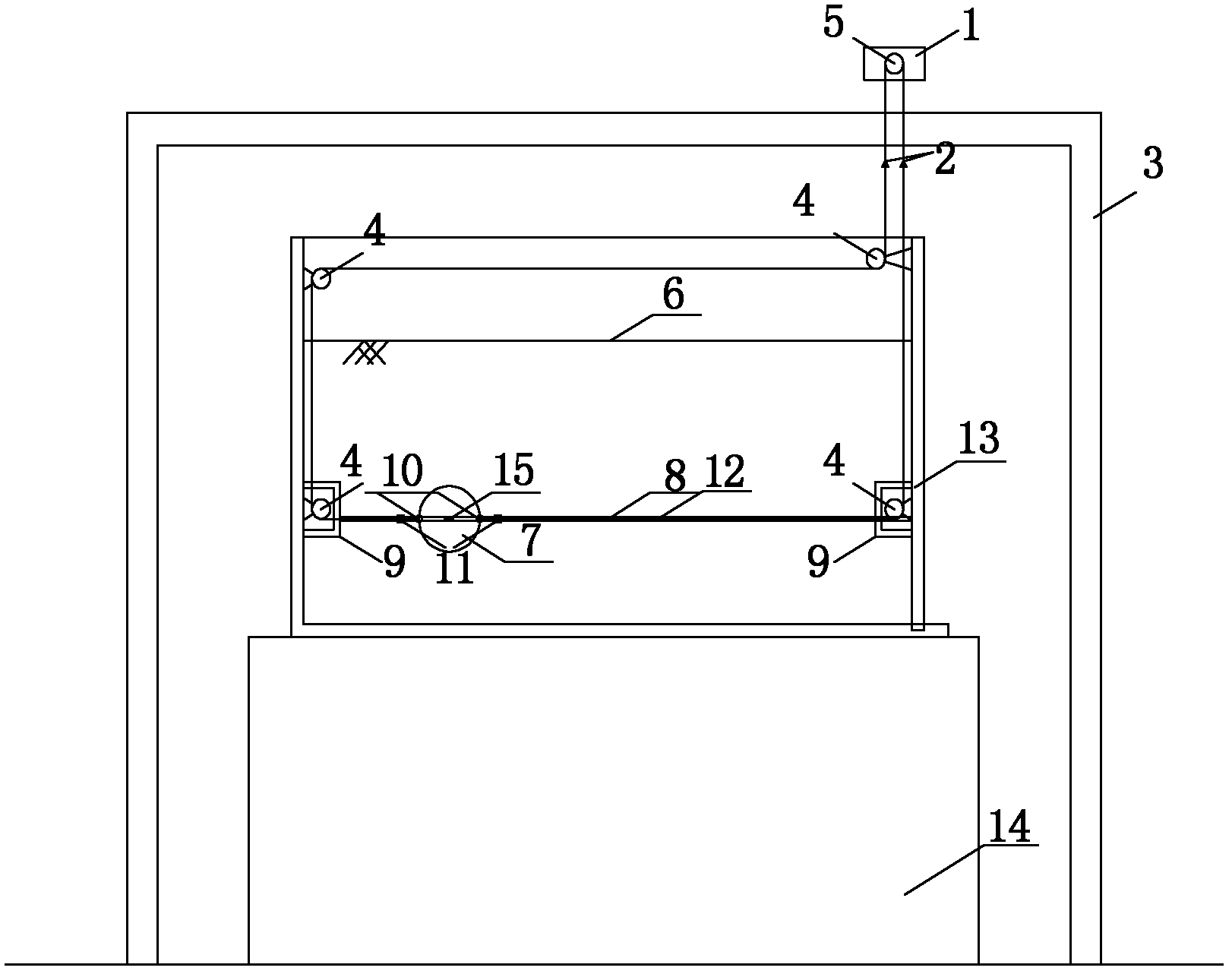

A dual-input characteristic test system for servo valve

ActiveCN110345132BRealize displacement inputReduce frictionFluid-pressure actuator testingMachine valve testingControl systemControl engineering

A dual-input characteristic testing system for a servo valve, including a measurement and control system and a test bench. The servo valve to be tested is installed on the working table of the test bench. An actuator is installed on the test bench, and the servo valve to be tested is driven by a loading signal. The actuator generates a displacement proportional to the loading signal, and feeds back to the mechanical feedback displacement input terminal of the servo valve under test; the measurement and control system includes the digital logic circuit of the lower computer and the human-computer interaction interface of the upper computer, and the user inputs the loading through the human-computer interaction interface of the upper computer. signal, the digital logic circuit of the lower computer converts the loading signal into a constant current source, applies it to the electric input terminal of the servo valve under test, and collects the displacement of the mechanical feedback displacement input terminal of the servo valve under test, and feeds it back to the human-computer interaction interface of the upper computer for further processing. Display, for the user to judge whether the dual-input characteristics of the servo valve meet the requirements. The invention can realize the function of separately testing the double-input characteristic of the servo valve, and achieves the purpose of judging the performance of the double-input characteristic.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Deviation-correctable circular belt side-carrying optical fiber reel conveying mechanism and optical fiber reel conveying method

The invention relates to a circular belt side support type optical fiber tray conveying mechanism capable of correcting deflection, which includes a frame, the frame includes two side frames distributed along the longitudinal direction, the side frames are provided with a belt supporting crossbeam, and an active belt below the belt supporting crossbeam Pulley, conveying motor, round conveyor belt and driven pulley, the round conveyor belt is connected to the driven pulley and the driving pulley, the belt supporting beam supports the round conveyor belt, and the fiber optic disc conveying groove is formed between the two side frames, and the fiber optic There are several optical fiber disk deviation correcting mechanisms distributed along the transverse direction in the disk conveying groove. The present invention provides a round-belt side-mounted optical fiber reel conveying mechanism that can prevent the optical fiber reel from rolling without a tray, and solves the problem that the existing optical fiber reel conveying mechanism transports the optical fiber reel through the tray. Prevent the increased workload caused by the rotation of the fiber optic tray and give the need to increase the space to store the tray.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

Spindle without spool

The invention belongs to the technical field of spindles, and particularly discloses a spindle without a spool. The spindle without the spool comprises a winding device, a transmission rod, an elastichousing and pin bolts. The winding device is cuboid-shaped, and is internally provided with a piston cavity, a thread cavity and a bottom cavity. The top of the piston cavity is provided with an airoutlet. The thread cavity is internally provided with an inside thread. The bottom cavity is communicated with the outside. The bottom cavity is internally provided with a first pin hole. The transmission rod is provided with a second pin hole and a thread block. The thread block is fixedly connected to the top of the transmission rod. The thread block is further provided with an outside thread. The top of the thread block is connected with a connecting rod. The top of the connecting rod is connected with a piston. The elastic housing is fixedly installed on the side wall of the winding device. A metal sheet is embedded in the elastic housing. An elastic cavity is formed between the elastic housing and the side wall of the winding device. The elastic cavity is communicated with the air outlet. The spindle without the spool is capable of solving the problem that the current spindle is necessarily provided with the spool, and a yarn roll collected by the spindle without the spool is a hollow cuboid.

Owner:宁波源生针织有限公司

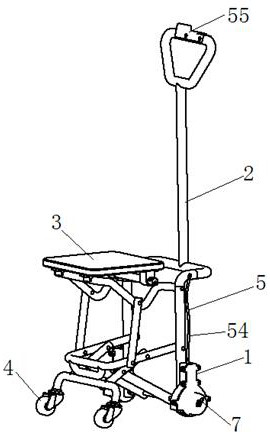

Wheeled Elderly Cane

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

An automatic equipment and method for high-speed laser marking and blanking and packaging

ActiveCN105691769BMarking speed is fastImprove counting accuracyTypewritersPackagingDisplay deviceEngineering

The invention discloses automatic equipment and method for achieving high-speed laser marking and discharging packaging. The automatic equipment comprises a vibration disc, a control cabinet, a discharging sliding rail, a height adjusting mechanism, a mounting column, a laser marking head, a displayer and a conveying mechanism. The discharging sliding rail is obliquely mounted above the control cabinet through the height adjusting mechanism. The mounting column is mounted on the control cabinet. The laser marking head and the displayer are mounted on the mounting column. The vibration disc is arranged at the high end of the discharging sliding rail. The conveying mechanism is mounted at the lower end of the discharging sliding rail. According to the automatic equipment for achieving high-speed laser marking and discharging packaging, automatic feeding, automatic marking, automatic counting and discharging packaging of nuts are combined together, meanwhile marking is conducted in a double-row manner, and high-speed marking can be achieved effectively.

Owner:EC PRECISION TECHJIANGSUCORP

Magnetic inflatable bottle holder for soda dispenser and soda dispenser

The invention relates to a holding device for a magnetic inflatable bottle used in a soda machine and the soda machine. Magnetic bottle holder that uses magnetism to hold and release CO 2 Inflatable bottle for easy CO 2 The replacement of the gas bottle is easy to operate and has high replacement efficiency. The safety mechanism of the soda machine of the present invention includes more than two pressure release channels, the pressure release is fast and balanced, and the safety is higher, and the release pressure threshold is adjusted by using the elasticity of the silicone sleeve and the change of the position and diameter of the release hole, the structure is simple, and Easy to control. The soda bottle of the soda water machine of the present invention has a longitudinal truncated plane on the bottle cap and the outer cylindrical surface of the bottle body, so that it is easy to twist and hold, the design is economical, and it is not easy to roll when placed horizontally. At the same time, the large mouth diameter makes filling and pouring easier.

Owner:真上康国际有限公司

An arm mobile grinding device based on an aerial work vehicle

ActiveCN113635160BIncrease elasticityNo scrollingGrinding work supportsPlane surface grinding machinesEngineeringMoving parts

The invention provides a mobile grinding device based on an aerial work vehicle, which relates to the field of grinding, to solve the problem of inconvenient installation and maintenance of the grinding mechanism and the lack of multi-level adjustment of grinding force when facing different grinding requirements. The structure, when light grinding is required, it is inconvenient to add heavy blocks for forced grinding, including the moving part, the bottom of the moving part is an arc structure, the bottom of the moving part is provided with threaded holes, and the moving table includes : Adjusting plate, the inside of the adjusting plate is provided with two round holes, the inside of the round hole is inserted with a guide rod, the bottom of the adjusting plate is in contact with the spring top on the outside of the guide rod, and the adjusting plate is inserted into the inside of the limiting groove. When it is necessary to adjust the grinding force, the inner end of the adjusting plate can be controlled to be inserted into the limit groove at different positions, so that the spring is compressed to different degrees, and the mobile platform can be pulled by different forces, so that the mobile platform can adjust the force for grinding. cut.

Owner:南通炫昱实业有限公司

Test device for testing flow characteristics of liquefied sand and test method

The invention discloses a test device for testing flow characteristics of liquefied sand and a test method. The device comprises a vibration platform and a model box. Plastic face plates are adopted on two lateral faces of the model box, a horizontal rail is respectively arranged at the symmetrical positions of the plastic face plates, and a rigid circular pipe is placed between the rails. A steel wire rope is led out from the rigid circular pipe and connected with and pulls a force sensor, leads out the model box, then is connected with a dynamic displacement sensor, and finally is connected to a positive and reverse speed regulation motor. The test method comprises enabling saturated sand in the model box to achieve a liquefied state through the vibration platform, the motor drives the steel wire rope and then guides the rigid circular pipe to perform horizontal movement on the rails to measure the speed of the movement of the rigid circular pipe and horizontal tension force exerted on the rigid circular pipe, so that apparent viscosity of the liquefied sand is calculated, and the flow characteristics of the liquefied sand are analyzed. The test device for testing flow characteristics of the liquefied sand and the test method has the advantages of being high in efficiency, small in boundary effect and the like.

Owner:HOHAI UNIV

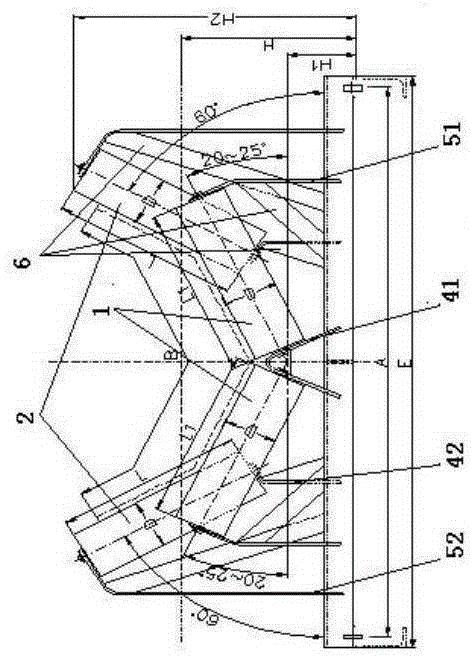

Groove angle-changeable supporting roller set achieving large inclination angle conveying

InactiveCN106628934AIncrease coefficient of frictionIncrease the conveying inclinationRollersDouble rowFastener

The invention provides a groove angle-changeable supporting roller set achieving large inclination angle conveying. The groove angle-changeable supporting roller set comprises middle rollers, side rollers, supports, middle support columns, side support columns, strengthening rib plates and fastening parts, the supporting roller sets are arranged in a double-row mode, the rollers which have the included angle smaller than 60 degrees are arranged in the front, and the rollers which have the large included angle of 60 degrees are arranged at the back. The side rollers can be equal or unequal in length. An intermediate roller of an ordinary roller set is designed to be two rollers which have a certain included angle, adhesive tape is subjected to grooving smoothly, the two side rollers are designed to form a 60-degree angle with the horizontal plane, by means of bearing and non-bearing continuous reciprocating opening and closing operation of the adhesive tape which is subjected to grooving on the supporting roller set, the coefficient of friction of the supporting roller set to the adhesive tape is increased, and therefore wrapping force, namely internal friction of the adhesive tape to materials and the internal friction between the materials are also increased; and it is guaranteed that sliding does not exist between the materials and the adhesive tape, and rolling does not exist between the materials. By adopting the groove angle-changeable supporting roller set achieving large inclination angle conveying, the conveying inclination angle of materials is increased; and by means of large inclination angle conveying, a route can be simplified, equipment investment can be reduced, and construction period can be shortened.

Owner:HENGYANG CONVEYING MACHINERY

Concrete tubular product convenient to transport

InactiveCN108644487AEnsure stabilityNo scrollingFlanged jointsCorrosion preventionEngineeringOil paint

The invention discloses a concrete tubular product convenient to transport. The concrete tubular product convenient to transport comprises pipelines, flange plates, reserved blocks and reinforcing ribs; the two ends of each pipeline are each fixedly provided with the corresponding flange plate, and fixed bolts are fixed to the edge positions of the flange plates; the reserved blocks are fixed to one end of the pipelines, and the two ends of one side of each pipeline are each fixedly provided with a first traction rope; the ends, away from the pipelines, of the first traction ropes are each fixedly provided with a hanging ring; reserved channels are uniformly arranged in the side walls of the pipelines; the reinforcing ribs are uniformly fixed in the reserved channels; an oil paint layer isarranged on the outer side of each pipeline; and an abrasion-resistant layer is arranged on the inner side of each pipeline. According to the concrete tubular product convenient to transport, due tothe fact that the two ends of one side of each pipeline are each fixedly provided with the corresponding hanging ring through the corresponding first traction rope, and the two ends of the other sideof each pipeline are each fixedly provided with a corresponding hook matched with the corresponding hanging ring through a second traction rope, after the pipelines are subjected to layout, stabilityof the pipelines can be ensured easily, rolling of the pipelines cannot happen, transporting is facilitated, and using is convenient and fast.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

New assembled hanger

ActiveCN111377354BNo scrollingNo slipBuilding material handlingLoad-engaging elementsStructural engineeringMechanical engineering

The invention discloses a novel assembled hanger. By setting the bottom frame, there are multiple partitions movable in the bottom frame, which can be used to hoist small-sized hoisting materials, and use the extrusion of the partitions to fix them to prevent them from slipping during hoisting Case. In the present invention, a pressing plate is provided on the movable sleeve of the vertical bar, and the downward extrusion of the pressing plate can be used to compress the large-size material hoisted on the fixed plate, so that the safety of the hanger hoisting is higher, and it also improves Lifting efficiency. The invention is a special hanger for small assembly-type building components, which can simultaneously meet the hoisting needs of larger components. The invention has the characteristics of simple structure, convenient operation, wide application range, safety and reliability.

Owner:CHINA FIRST METALLURGICAL GROUP

Sphere coating machine

ActiveCN105834071AAccelerate solidificationNo scrollingLiquid surface applicatorsCoatingsCold airSpray coating

The invention relates to a sphere coating machine which includes a coating bowl, a sphere inlet pipe and a sphere collecting shield. The coating bowl is driven by a driving motor and can rotate around the axial line itself. A bowl wall of the coating bowl is made of a hard mesh material. The sphere inlet pipe is connected to the bottom of the coating bowl through a bearing. The coating bowl can rotate freely relative to the sphere inlet pipe. The sphere collecting shield sleeves the periphery of the coating bowl and is fixed on a machine body of the sphere coating machine. A sphere outlet pipe is installed in the sphere collecting shield. A cold air ring is installed on the top of the sphere collecting shield. An air outlet of the cold air ring is tangent with the inner wall of the sphere collecting shield. A spray coating pipe is fixedly installed right above the coating bowl. One end of the spray coating pipe is connected to a liquid coating chamber. A sprinkler is arranged on the other end of the spray coating pipe. The sphere coating machine can coating spheres uniformly, is increased in speed of drying the coating, and is effectively increased in coating successful rate of the spheres.

Owner:南通梅丽塔智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com