Support arm moving and grinding device based on overhead working truck manufacturing

A kind of high-altitude operation vehicle and grinding technology, which is applied in the direction of grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, manufacturing tools, etc., and can solve the problems of staff injury, weak fixation, arm shaking or displacement, etc. Problems, to achieve the effect of improving safety, strong elasticity, and strengthening the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

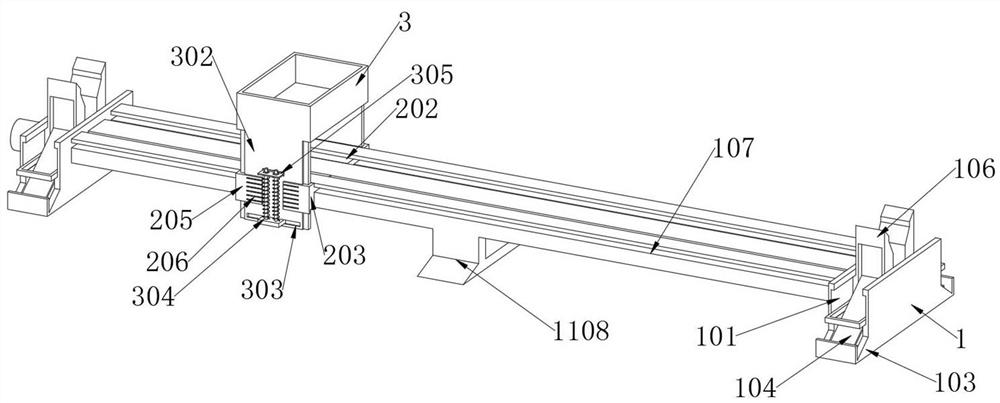

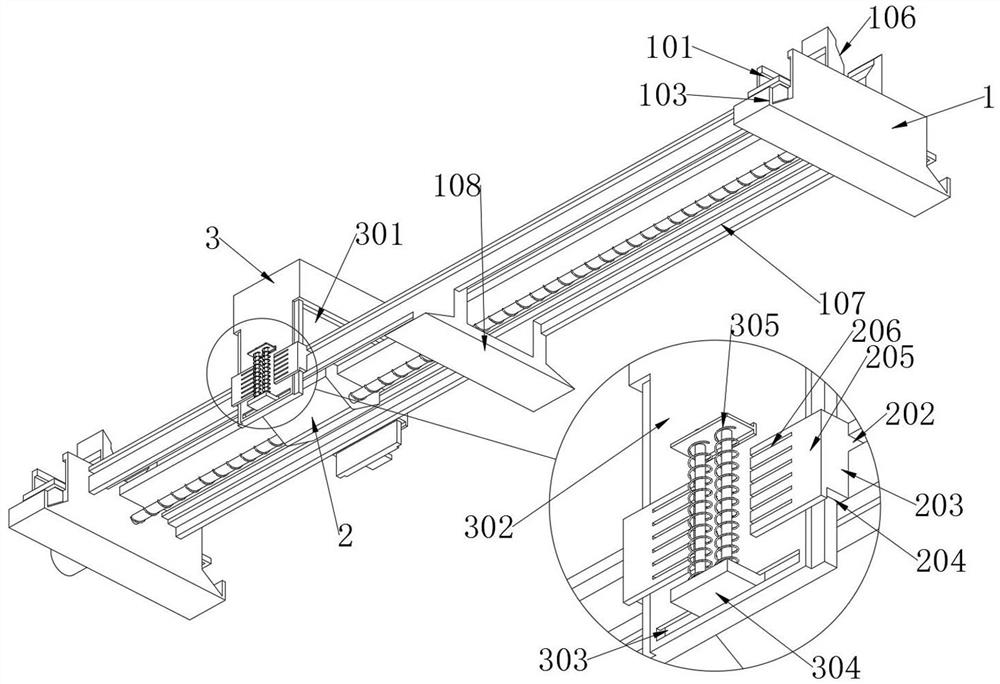

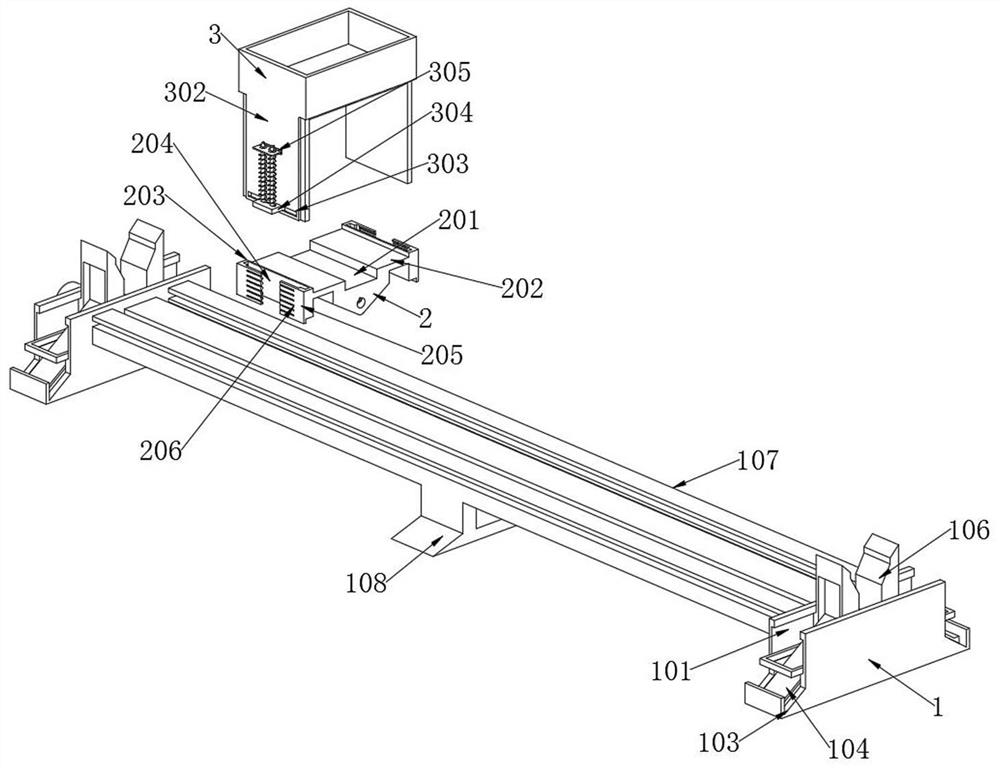

[0027] as attached figure 1 to attach Figure 8 Shown:

[0028] The invention provides a mobile grinding device for a support arm manufactured on the basis of an aerial work vehicle, which includes a main body 1; the main body 1 is a rectangular structure, and there are two main bodies 1, which are used to firmly support the two ends of the support arm. A servo motor is installed on the outside of the main body 1, which is used to control the forward and reverse rotation of the screw. The right side of the servo motor is provided with a screw, which is used to insert into the threaded hole of the moving part 2, and then drive the moving part 2 and the moving table 3 Reciprocating movement, so that the plane of the support arm can be reciprocated and ground. The right end of the screw rod is connected to the main body 1 at the right end. The main body 1 includes: a push plate 104. The push plate 104 is an inclined plate structure, so that it can be inserted into the The insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com