Novel assembly type hanging bracket

A prefabricated, hanger technology, used in transportation and packaging, load hanging components, construction, etc., can solve the problems of unsuitable hangers, poor safety, and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

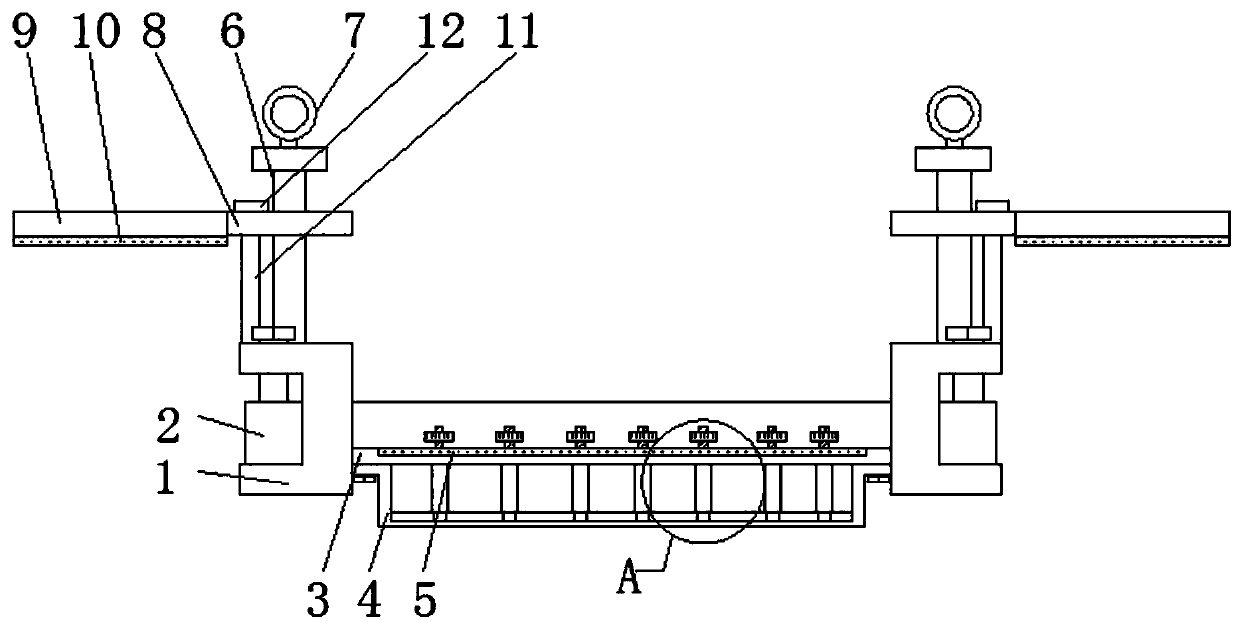

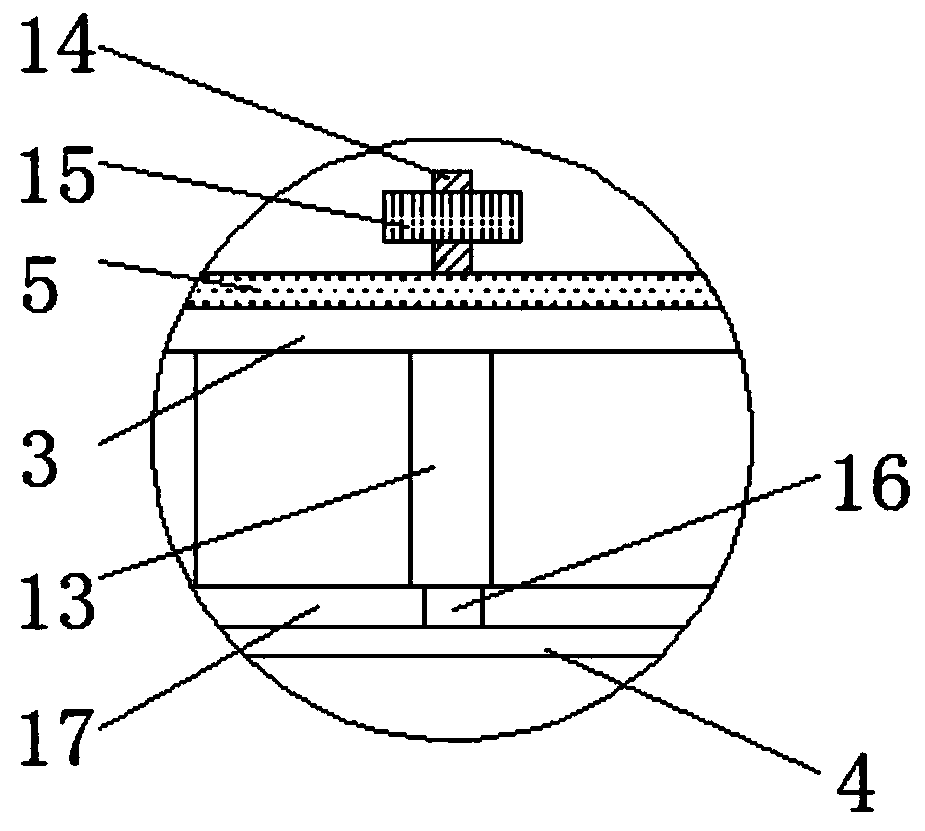

[0024] Referring to the accompanying drawings, the assembled hanger of the present invention includes two I-shaped plates 1 and a fixing plate 2, and also includes a "U"-shaped bottom frame 4 fixed and installed on the bottom end of the fixing plate 2 by bolts, and the fixing plate 2 is inserted into the two The two ends of the I-shaped plate 1 are fixed by bolts, the bottom of the front side of the fixed plate 2 is welded with a convex plate 3, and a plurality of partition plates 13 are vertically arranged in the bottom frame 4, and the tops of the plurality of partition plates 13 are all fixed. A push rod 14 is inserted, and the top end of the push rod 14 is arranged through the through groove on the convex plate 3, the push rod 14 is provided with a turning sleeve 15, and the top ends of the two I-shaped plates 1 are vertically welded with v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com