Deviation-correctable flat-belt side-supporting optical fiber tray conveying mechanism and optical fiber tray conveying method

A technology of conveying mechanism and optical fiber tray, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of increasing space for storing trays and increasing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

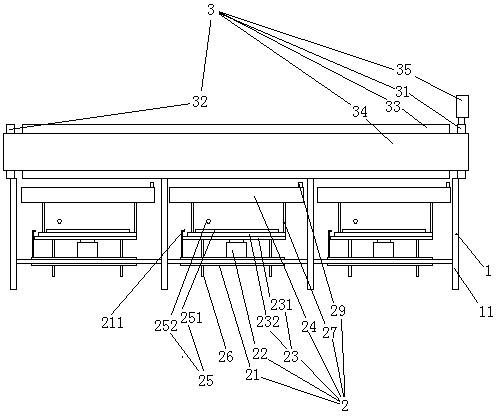

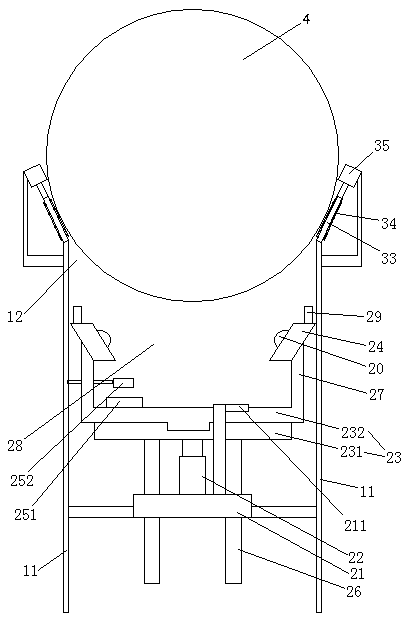

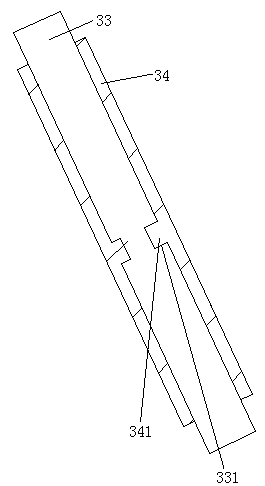

[0024] see figure 1 , figure 2 with image 3 , a deflection-correctable flat-belt side-support type optical fiber reel transport mechanism, including a frame 1. The frame includes two side frames 11 distributed longitudinally. The upper end of side frame is provided with conveyer belt 3. The conveyer belt comprises a driving conveying roller 31, a driven conveying roller 32, a conveying motor 35 for driving the driving conveying roller to rotate, a supporting plate 33 and a rectangular flat belt 34 with a cross section arranged on the driving conveying roller and the driven conveying roller. The flat strips are joined together end to end to form a circular structure. The supporting plate 33 is located in the area enclosed by the flat strips. The flat strap holds the back of the portion where the flat strap supports the fiber optic tray. A positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com