Spindle without spool

A technology of spindles and bobbins, which is applied in textiles and papermaking, can solve the problem that the spindles must be equipped with bobbins, and achieve the effect of easy handling, transfer and stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

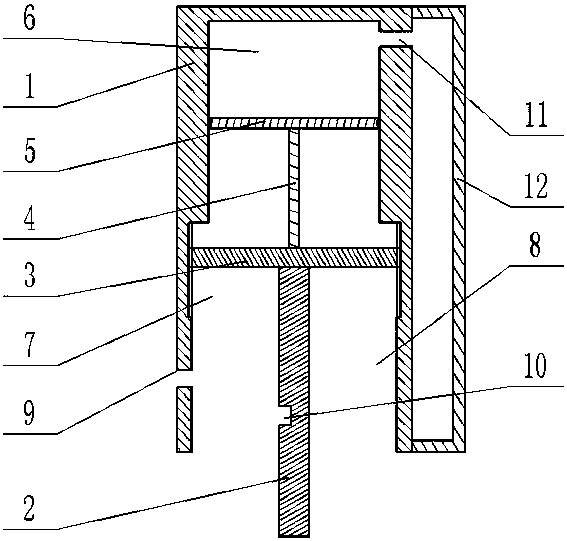

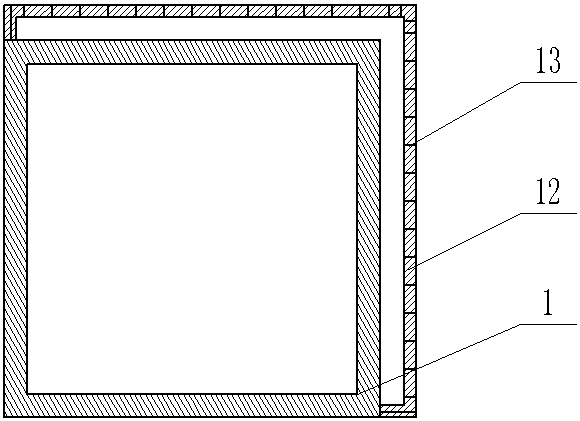

[0012] The reference signs in the drawings of the description include: winding device 1, transmission rod 2, threaded block 3, connecting rod 4, piston 5, piston cavity 6, threaded cavity 7, bottom cavity 8, first pin hole 9 , The second pin hole 10, the air outlet hole 11, the elastic shell 12, the metal sheet 13.

[0013] Such as figure 1 , figure 2 As shown, the present embodiment does not need the spindle of the yarn bobbin, including the winding device 1 , the transmission rod 2 and the elastic shell 12 . The yarn winding device 1 is in the shape of a cuboid, and the yarn winding device 1 is provided with a piston cavity 6, a thread cavity 7 and a bottom cavity 8 from top to bottom, and these three cavities are connected in sequence and the bottom cavity 8 is connected to the outside world connected. The diameter of described piston cavity 6 is less than the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com