Building steel pipe moving and transporting device

A technology of transportation devices and steel pipes, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as inconvenient transportation, easy rolling, stacking of steel pipes, etc., achieve the effect of reasonable structural design and reduce safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

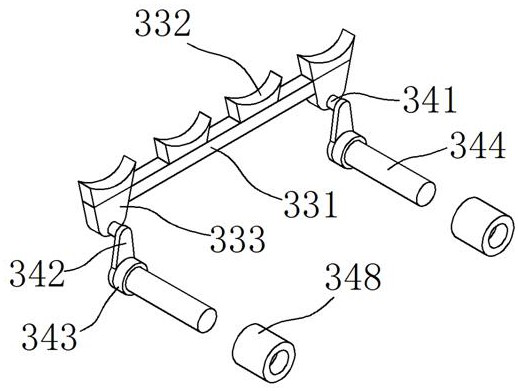

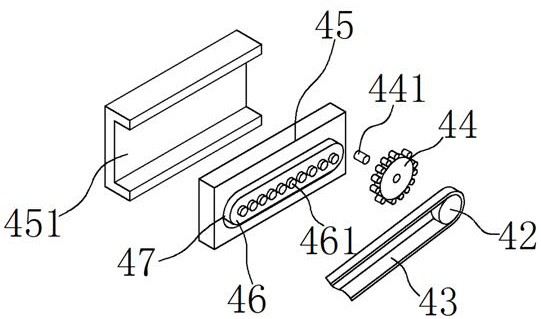

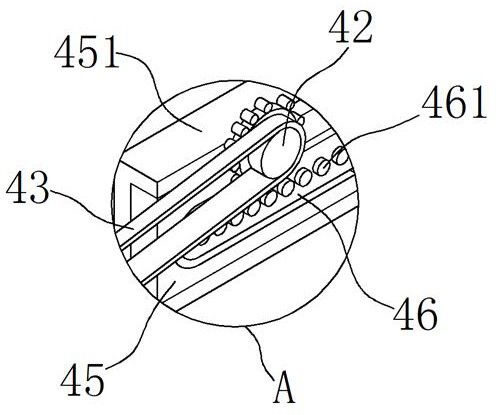

[0028] Refer to the attached Figure 1-4 , a construction steel pipe mobile transportation device, including a first inclined slideway 1, a translation structure 3 is provided on one side of the first inclined slideway 1, and the translation structure 3 includes two symmetrically arranged support plates 31, two A plurality of blocking tooth plates 32 are evenly arranged on the top of the support plate 31 , and a translation unit 33 is arranged between the two support plates 31 .

[0029] In this embodiment, if the steel pipe is to be sent to a transport trolley or other transfer tools, a second inclined slideway 2 can be set at this time, so that the steel pipes slide down one by one and fall into the transport trolley at equal time intervals; The height of the first blocking tooth plate 32 is set to be adjustable, and the height of the first blocking tooth plate 32 is adjusted by sensing the pressing force on the side.

[0030] The translation unit 33 includes a moving plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com