Three-hole half-section guide groove device

A technology of guide groove and hole type, which is applied in the field of three-hole half-cut guide groove device, which can solve the problems of low material utilization rate, high cost of production spare parts, and short service life, so as to achieve long service life, reduce spare parts, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

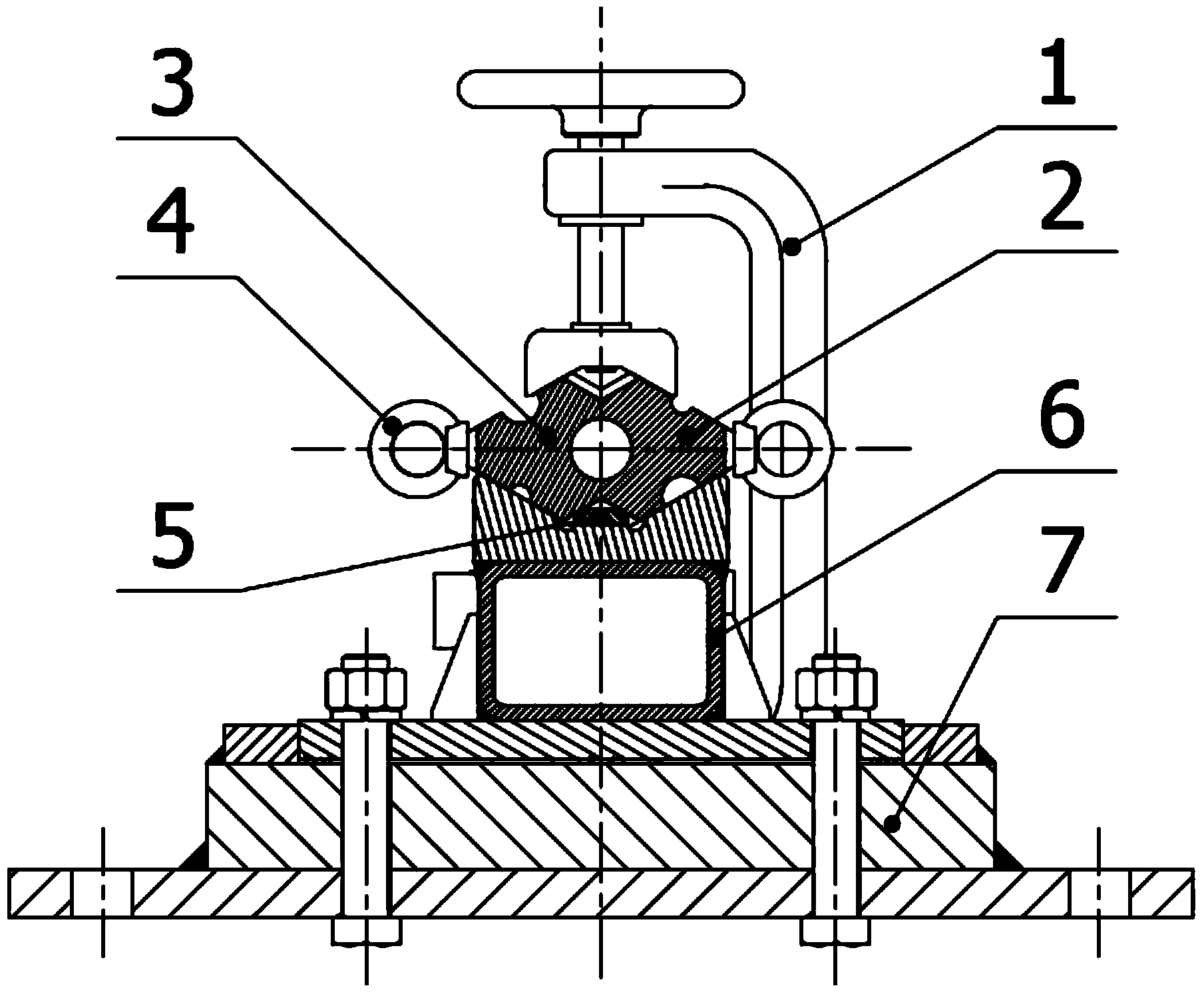

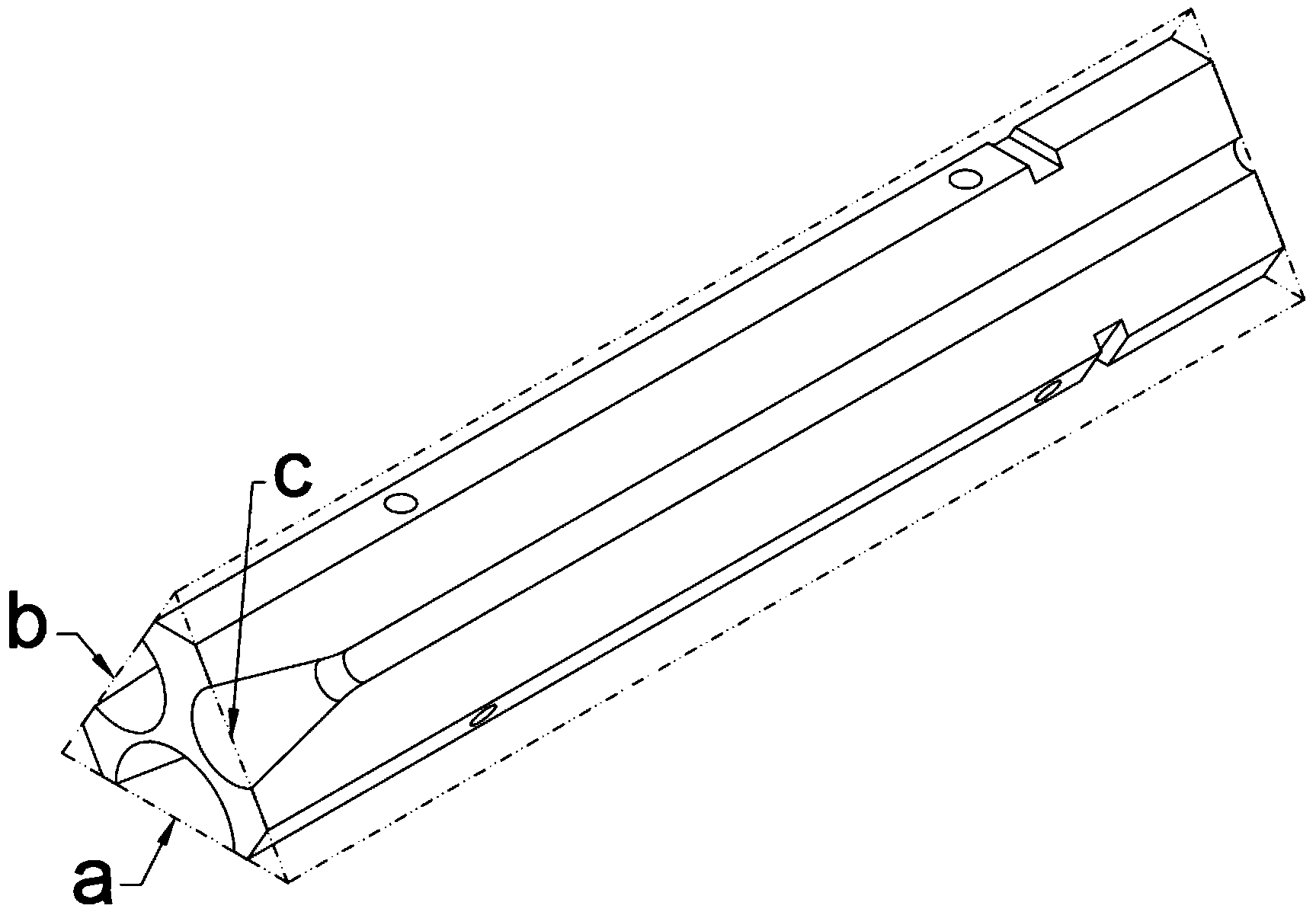

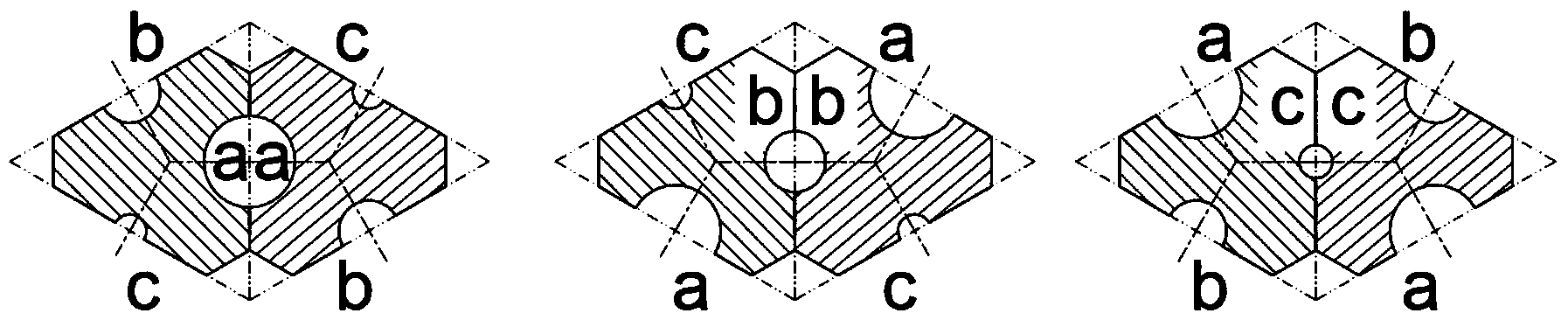

[0019] The invention includes clamps, a first guide groove 2, a second guide groove 3, an eyebolt nut, a key, a supporting water beam and a base. The first guide groove 2 and the second guide groove 3 are fixed on the supporting water beam (6), the upper part of the first guide groove 2 and the second guide groove 3 is pressed by the clamp 1 fixed on the supporting water beam 6, and the eye nut 4 is installed on the first guide groove 2 and the second guide groove 3, the key 5 is installed on the V-shaped groove seat supporting the water beam 6, and the supporting water beam 6 is installed on the base 7.

[0020] The first guide groove 2 and the first guide groove 3 are completely the same.

[0021] A V-shaped groove seat is arranged on the supporting water beam. The clamps are press-fitted on the tops of the first guide groove 2 and the second guide groove 3 . Eyebolt nuts are installed on guide groove one and guide groove two. The key is installed in the keyway of the V-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com