A Simplified Method for Using Spherical Point Locations

A point positioning and ball point technology, applied in positioning devices, clamping, support, etc., can solve problems such as complex processing technology, unreliable positioning, and difficult processing, so as to reduce the difficulty of subsequent processing, facilitate labeling, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

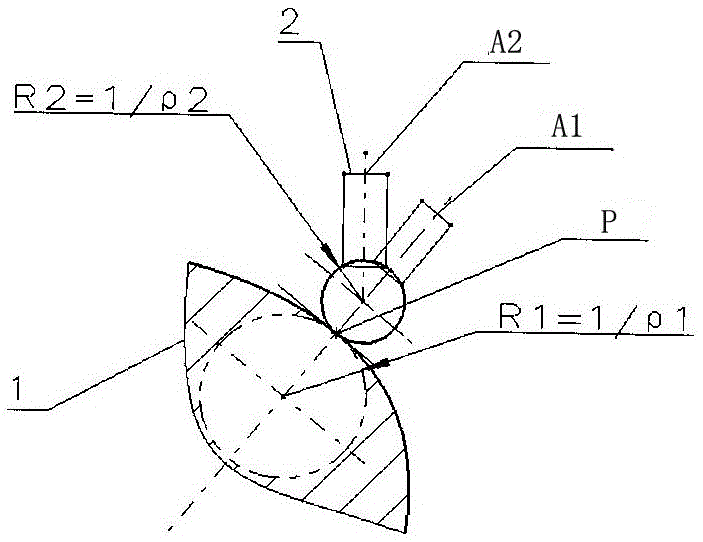

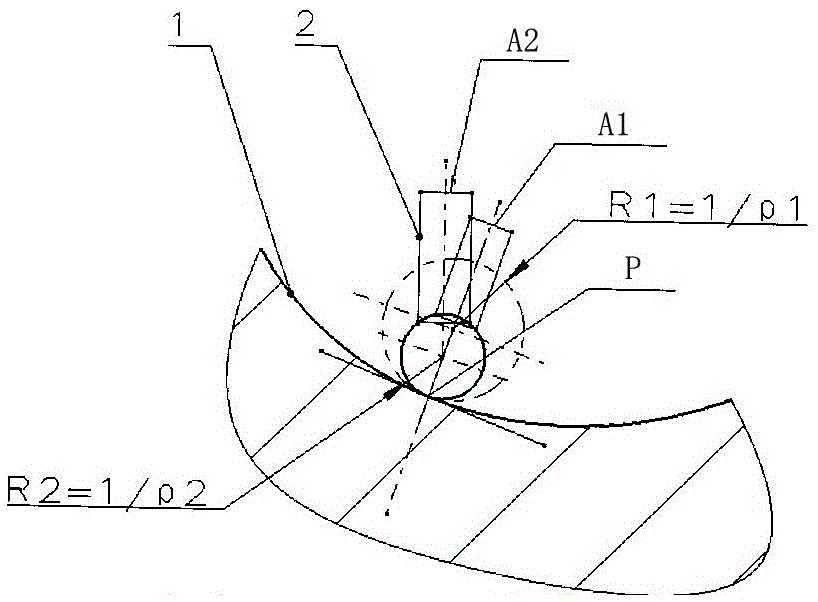

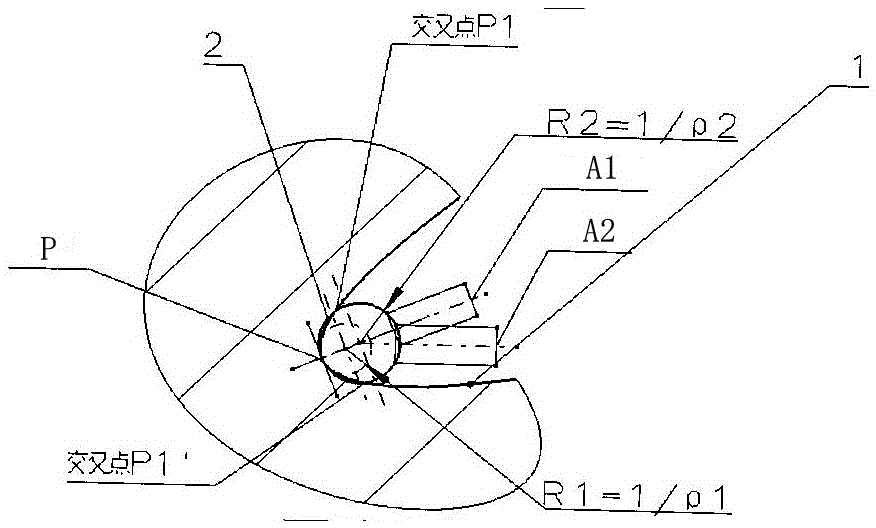

[0016] Such as Figure 1 to Figure 3 As shown, a simplified method of using spherical point positioning includes the following steps:

[0017] (1) Determine whether the curved surface is convex or concave according to the structural characteristics of the curved surface part 1, and determine the positioning point on the curved surface part. If it is in the concave form, it is necessary to ensure that the curvature radius ρ2 of the ball point locator 2 is larger than the curved surface The radius of curvature ρ1 of the positioning point of the part;

[0018] (2) Make the spherical surface of the ball point locator 2 tangent to the curved surface of the curved surface part 1, and ensure that the tangent point P is the positioning point. At this time, the ball handle of the ball point locator 2 is at position A1, and the ball point locator 2 The axis of the ball handle is collinear with the center of the sphere and the tangent point P;

[0019] (3) Under the condition that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com