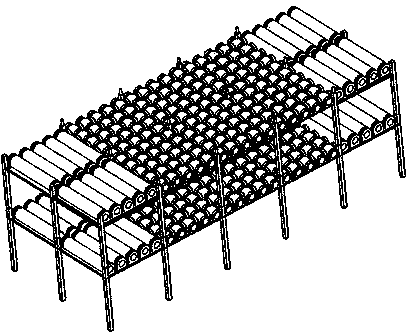

A fully automated shelf with precise positioning

A fully automated and precise technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of high overall structure cost, large shuttle car space, and insufficient mechanical strength, so as to improve utilization efficiency and work efficiency, and facilitate unitized management , The effect of simple warehouse structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

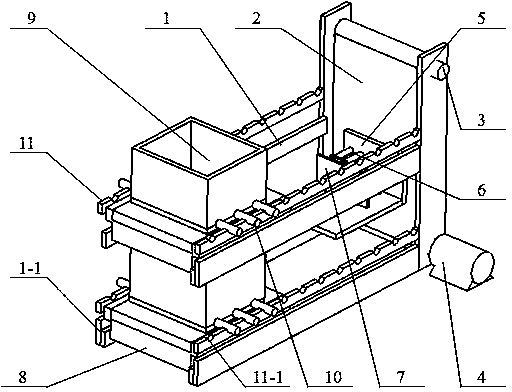

[0028] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

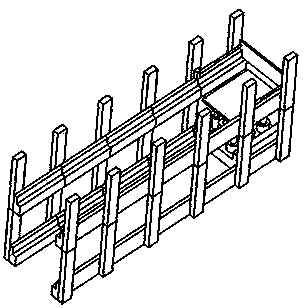

[0029] The invention provides a fully automated shelf with precise positioning. The three-dimensional warehouse is equipped with a lifting bracket outside the shelf bracket. There is a push plate inside the lifting bracket, and a special cargo box is designed. The side and bottom of the cargo box are made of iron, and the lifting The push plate of the support and the top plate of the shuttle trolley are designed to be electromagnetic, and the precise positioning of the goods can be realized through the movement of the lifting bracket and the shuttle trolley and the corresponding control. Since the cargo boxes with the same specifications are designed, it is easier to realize the unitized management of the cargo, and the entire warehouse structure Simple and low cost, so it has a good market prospect.

[0030] As a specific embodiment of the present invention, the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com