A three-way solenoid valve

A technology of three-way solenoid valve and spool, applied in multi-way valves, valve details, valve devices, etc., can solve the problem of high cost, achieve the effects of controlling manufacturing costs, improving processing technology, and simple structural layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

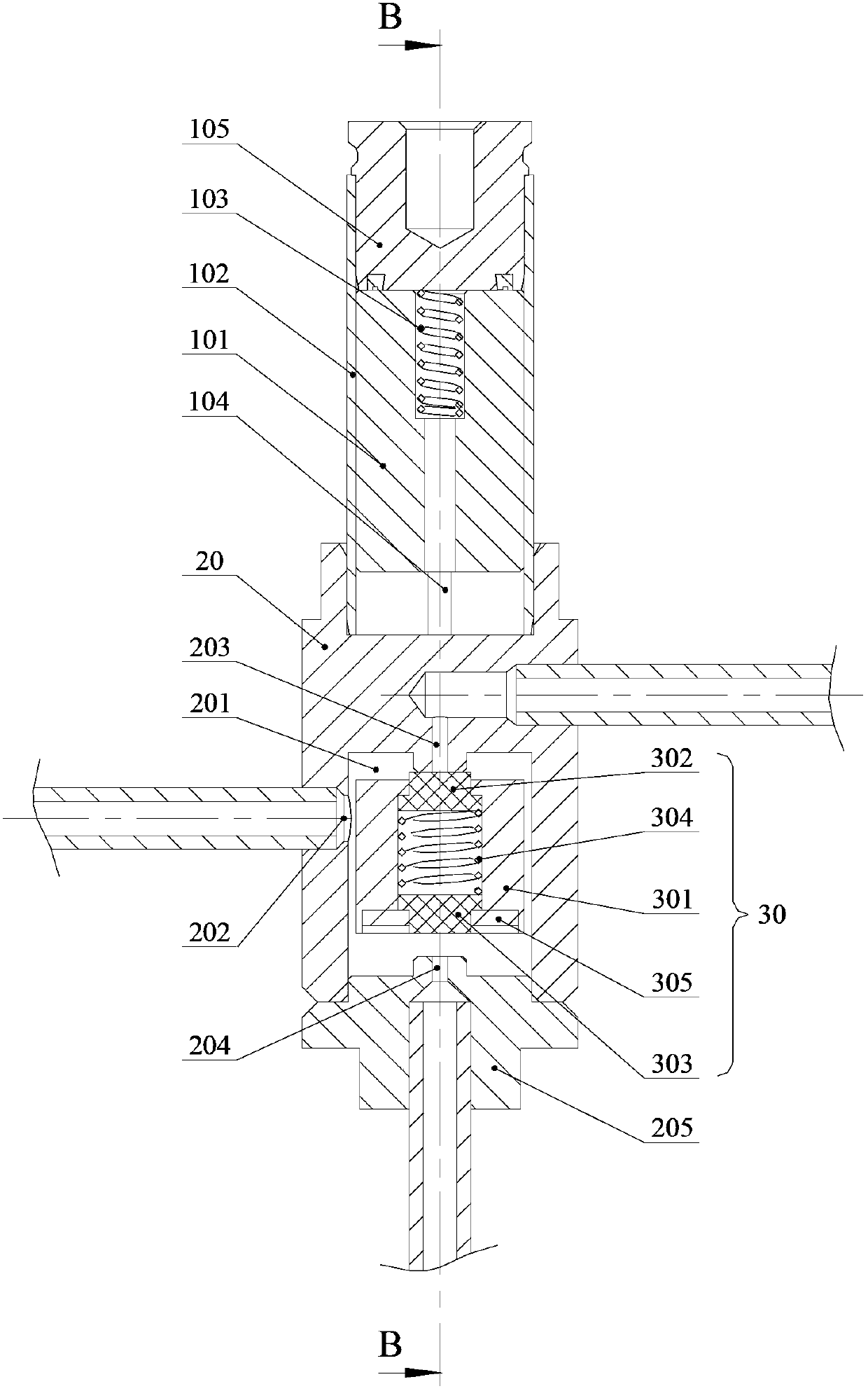

[0030] The core of the present invention is to provide a three-way solenoid valve, which can effectively improve the processing technology through structural optimization, and at the same time, provide a reliable guarantee for controlling the manufacturing cost of the product. A detailed description will be given below in conjunction with the accompanying drawings of the description.

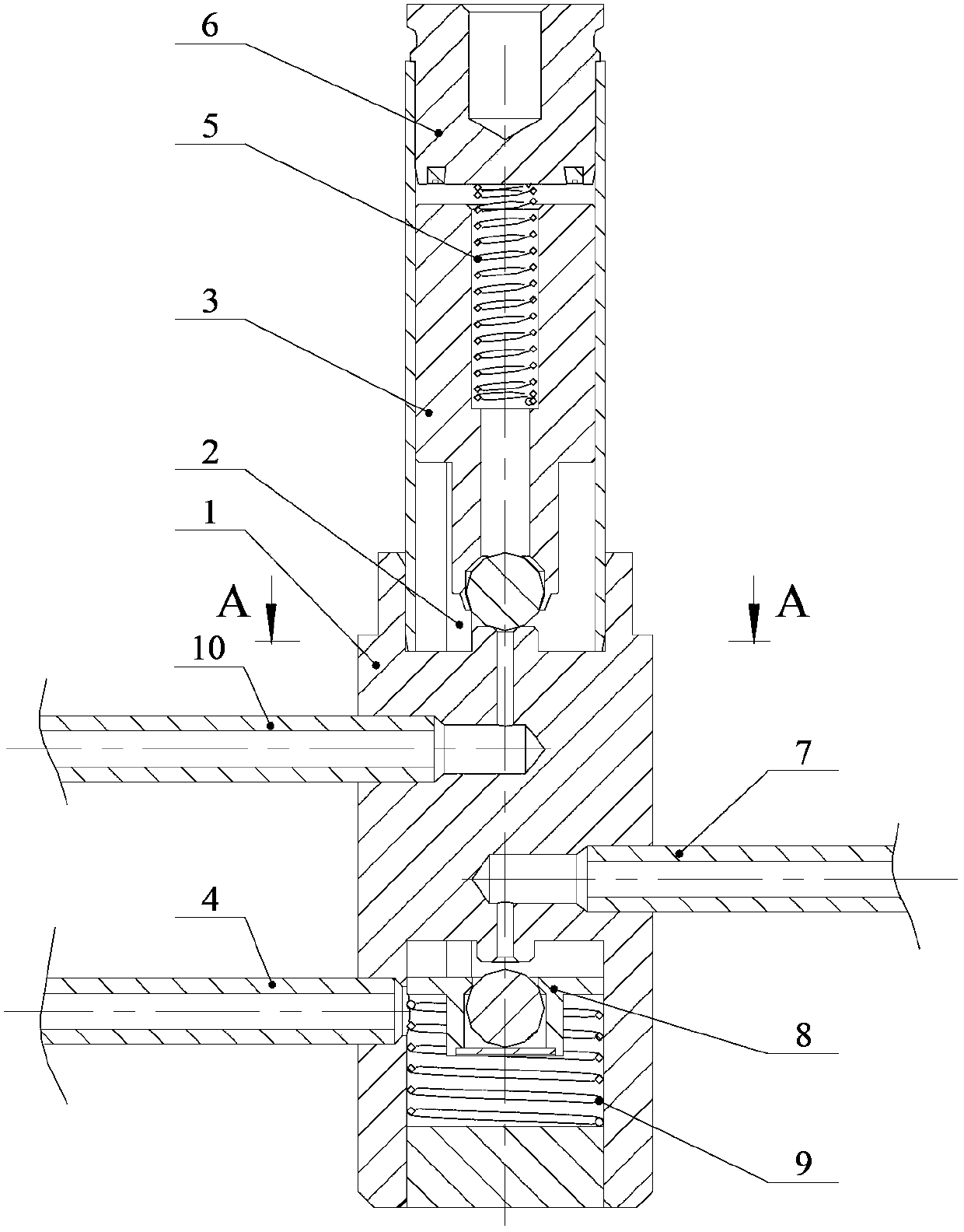

[0031] See image 3 , which shows a schematic diagram of the overall structure of the three-way solenoid valve in this embodiment.

[0032] Such as image 3As shown, the driving part of the three-way solenoid valve is mainly composed of a suitable coil (not shown in the figure) and a core iron 101, the core iron 101 is built in the sleeve part 102 fixedly connected with the valve seat 20, and A second elastic member 103 is arranged between the core iron 101 and the blocking member 105 of the casing 102; specifically, after the coil is energized, an axial force for switching to the second worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com