A method and device for maintaining and replacing crude oil standpipes on an offshore platform

A technology for maintenance and replacement of offshore platforms, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of long construction period, high cost, and only maintenance of riser sections above the water surface, etc., to achieve shortening The time and effect of reducing cost output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. The schematic implementation and description of the present invention are used to explain the present invention, but are not intended to limit the present invention.

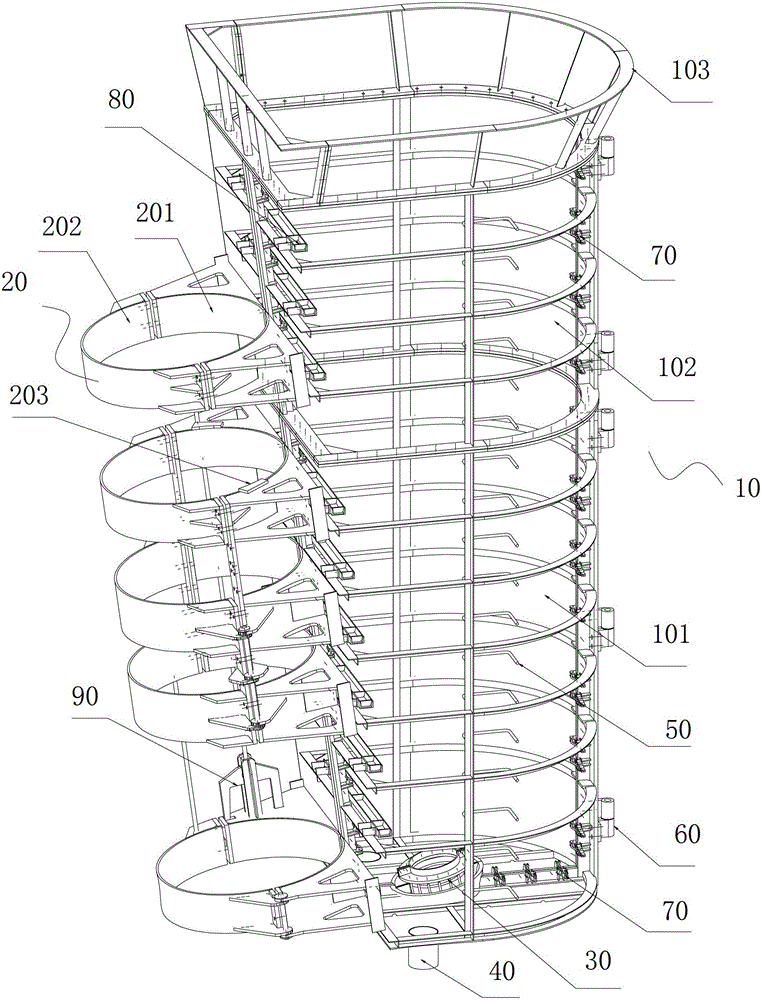

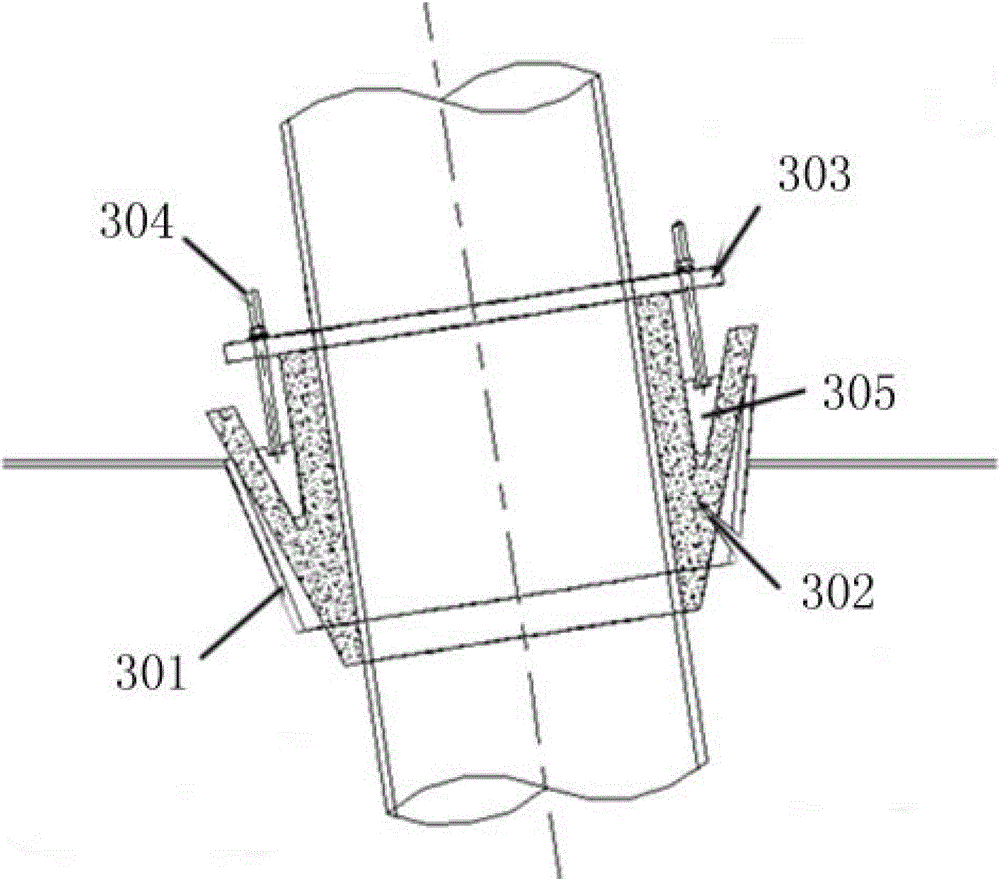

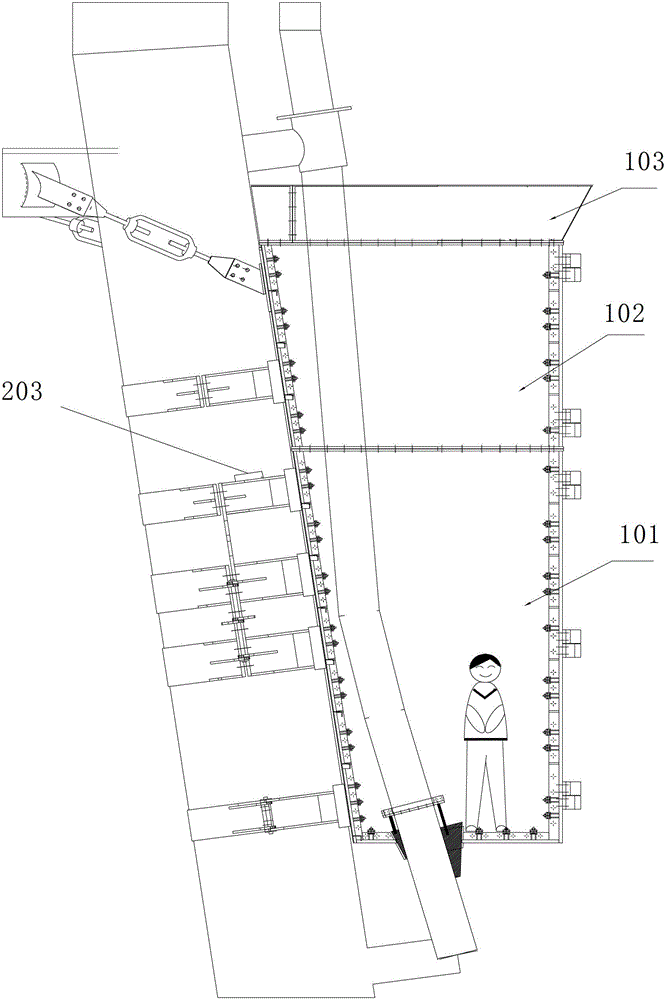

[0035] see figure 1 , which is a schematic diagram of the main structure frame of an offshore platform crude oil riser maintenance and replacement device according to the present invention, including a water-resistant tank 10, a water-resistant tank pipe clip 20, a frustum-shaped sealing assembly 30 and a water pump. The water-proof tank 10 is a cavity structure with an opening upward, and a through hole is provided at the bottom for the crude oil standpipe to pass through. The frustum-shaped sealing assembly 30 is used for sealing the gap between the crude oil riser and the watertight tank after the crude oil riser passes through the through hole. The water pump is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com