Flange

A flange and fixed flange technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problem of time-consuming and laborious, and achieve the effect of small tool requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

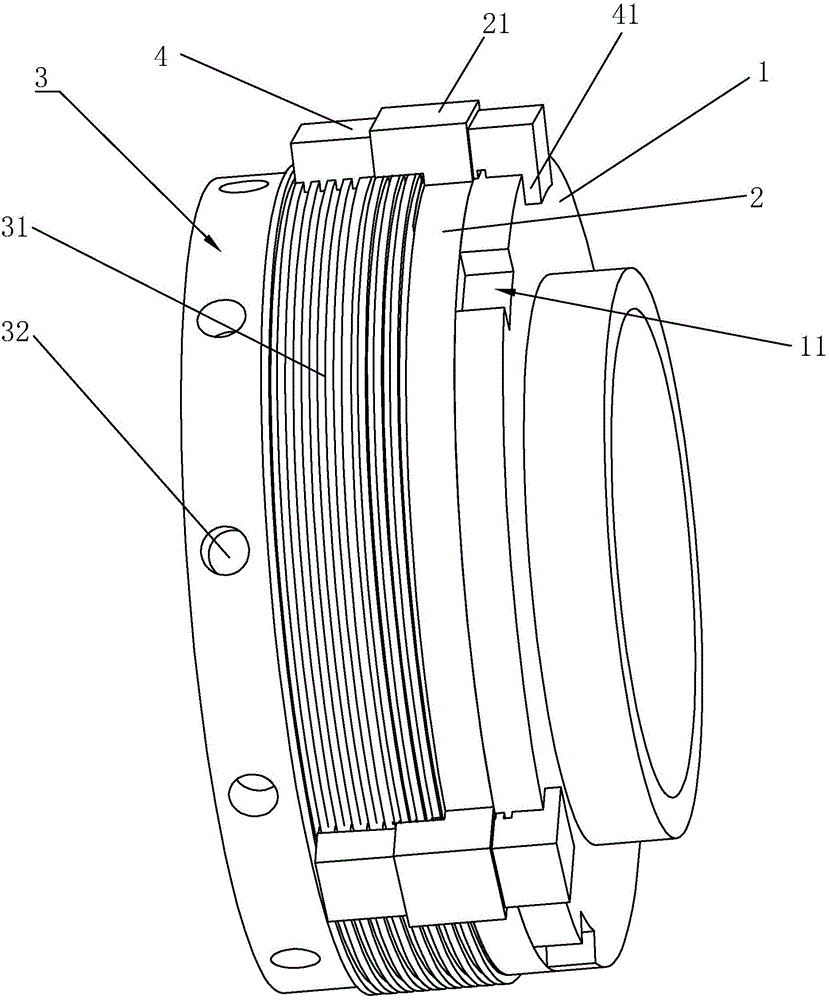

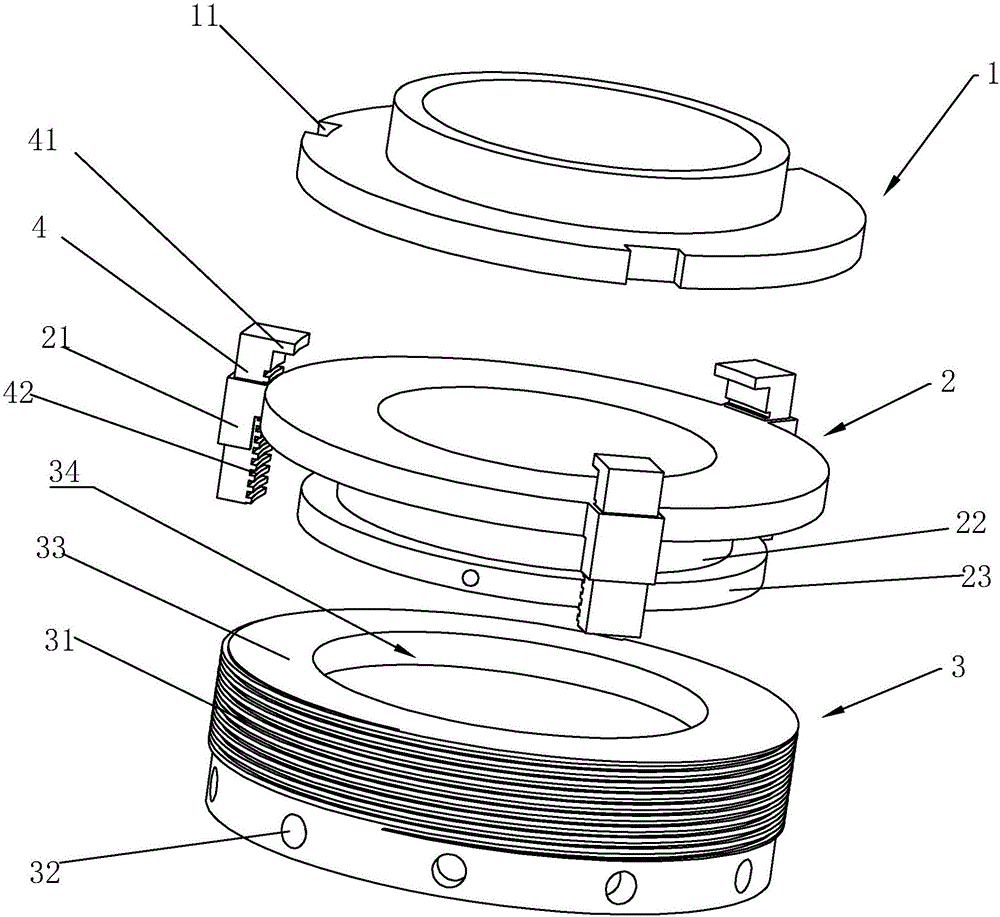

[0025] refer to Figure 1 to Figure 4 The embodiment of the flange of the present invention will be further described.

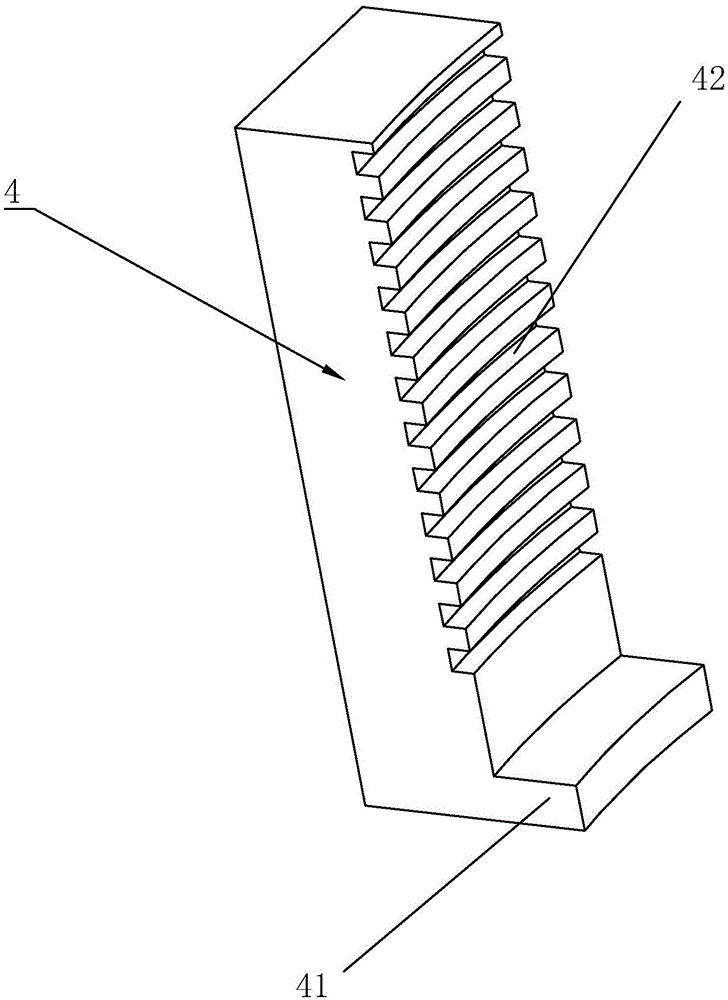

[0026] A flange, including a fixed flange 2 and a connecting flange 1, a fixing device is provided between the fixed flange 2 and the connecting flange 1, and an axial slide groove 24 is provided on the fixed flange 2, The fixing device includes a claw 4 arranged on the chute 24, the claw 4 is provided with a clamping part for fixing the connection flange 1, and the fixed flange 2 is also provided with a drive claw 4 axis A drive mechanism for moving in the direction, the drive mechanism includes a drive wheel 3 rotating in the circumferential direction, the drive wheel 3 is provided with a guide rail 31 spirally wound around the central axis, and the claw 4 is provided with a guide rail 31 adapted to The guide groove 42 (the driving mechanism can also be replaced by other means, such as hydraulic pressure).

[0027] By adopting the above-mentioned technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com