Heat preservation pipe fitting for steel bushing by steam with corrugated compensation end cap

A technology of corrugation compensation and pipe fittings, which is applied in the direction of heat preservation, pipe components, and pipe protection through heat insulation, can solve problems such as low safety, abnormal operation of pipe networks, and high maintenance costs, and achieve the effect of increasing the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

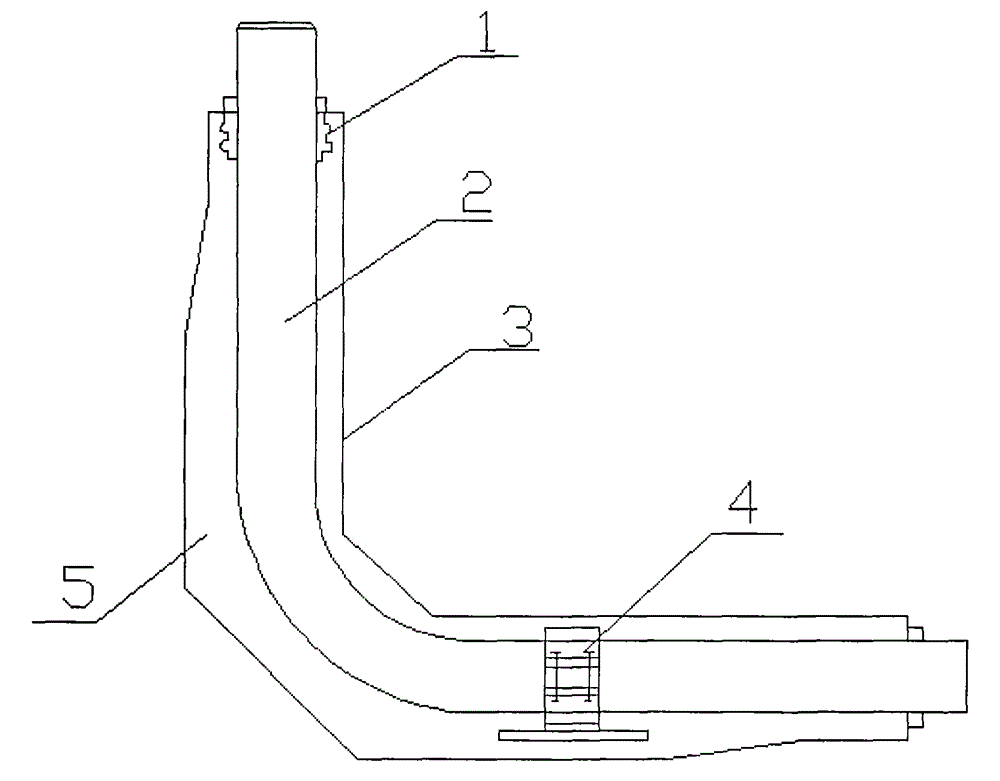

[0012] Such as figure 1 As shown, a steel-jacketed steam insulation pipe fitting with a corrugated compensation end cap of the present invention includes an inner working pipe fitting 2, and an outer protective pipe fitting 3 arranged outside the inner working pipe fitting 2, and the other side of the inner working pipe fitting 2 is An insulation layer 5 is provided.

[0013] Wherein, the upper end of the longitudinal pipe of the inner working pipe 2 is provided with a corrugated compensation end cap 1, so that the cooperation between the outer protective pipe 3, the insulation layer 5 and the inner working pipe 2 is more sealed.

[0014] The horizontal pipe of the inner working pipe 2 is provided with a sliding bracket 4, which has the function of isolating the steam pipe when the steam leaks, so that it only affects the small section of the pipe where the leak occurs.

[0015] The beneficial effects of the present invention are: the present invention utilizes the sliding br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com