Method for manufacturing multi-curved surface lens light distribution device

A multi-curved, light distributor technology, applied in semiconductor devices, instruments, optics and other directions of light-emitting elements, can solve the problems of low utilization rate of light energy, large size of lamps, inconvenient installation, etc., achieve small size, reduce loss, and install handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

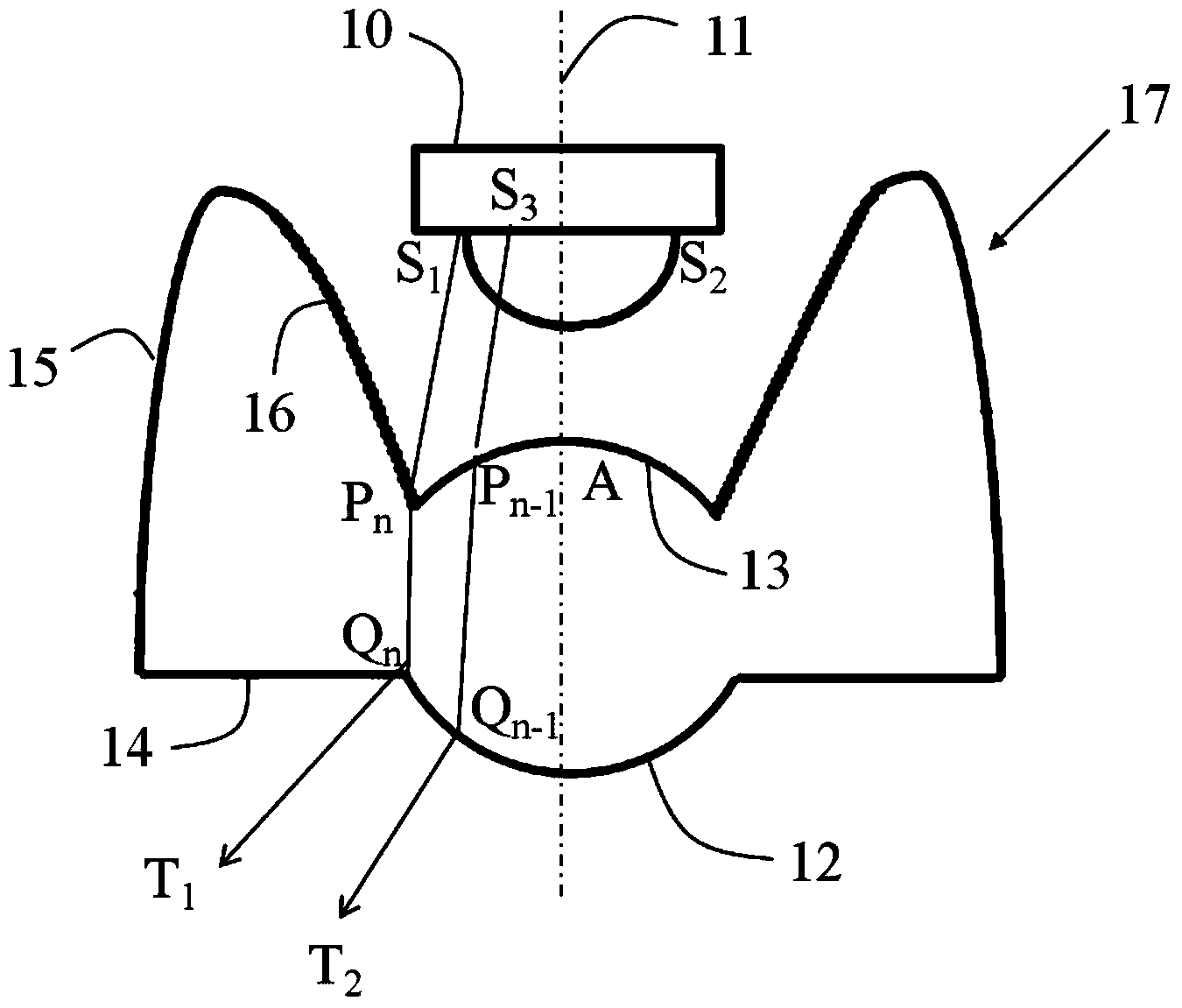

[0014] The method for manufacturing a multi-curved lens light distribution device involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0015]

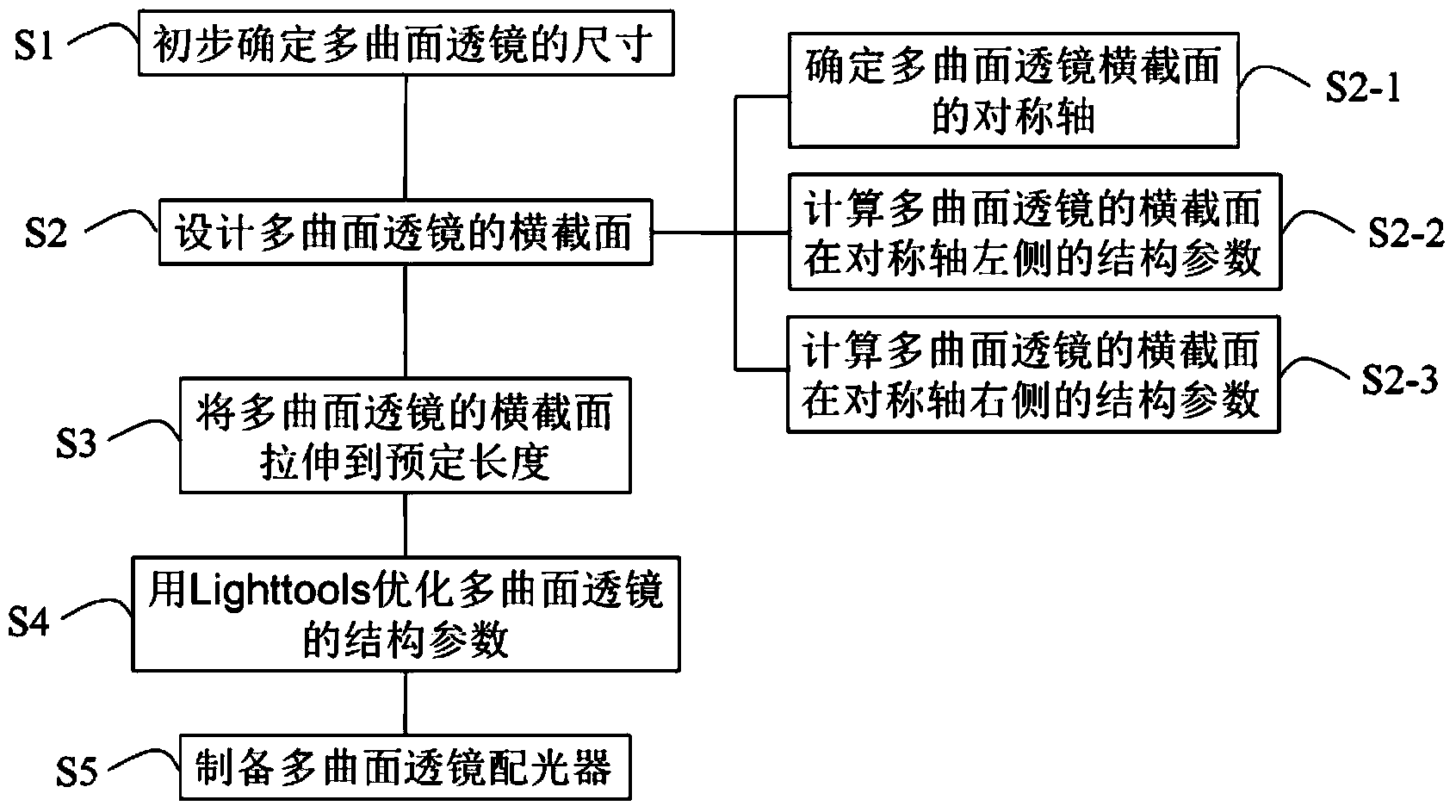

[0016] figure 1 is a flowchart of a method for manufacturing a polycurved lens.

[0017] Such as figure 1 As shown, the method for manufacturing a multi-curved lens light distributor includes the following steps:

[0018] Step S1: The LED street lamp used in this embodiment has a width of 9 mm and a length of 8 mm. In order to ensure that all the light emitted by the LED street lamp is refracted by the light distribution device to obtain a rectangular lighting spot, and to reduce the size of the light distribution device as much as possible, multiple The width of the curved lens is set to be 4 to 5 times the width of the LED street lamp, and the length of the multi-curved lens is determined according to the number of LED street lamps installed. In this embodiment, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com