Converter valve tower and valve hall using the same

A converter valve and valve tower technology, applied in the field of converter valve valve tower, can solve the problems of inconvenient maintenance of converter valve valve tower, and achieve the effects of improving installation and maintenance efficiency, convenient maintenance operation and high insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

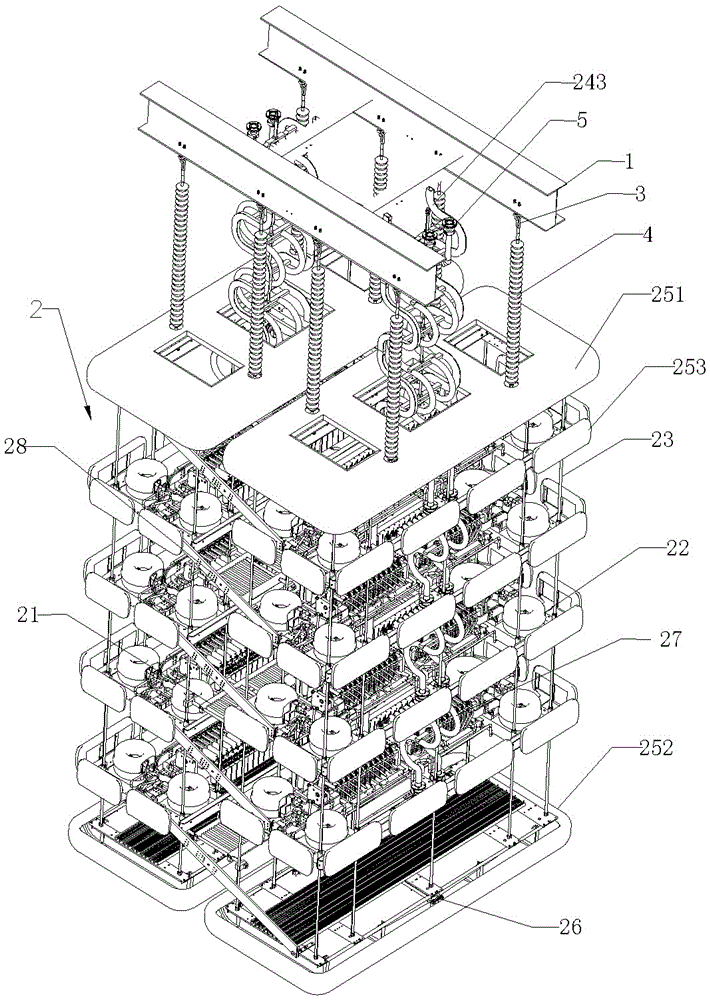

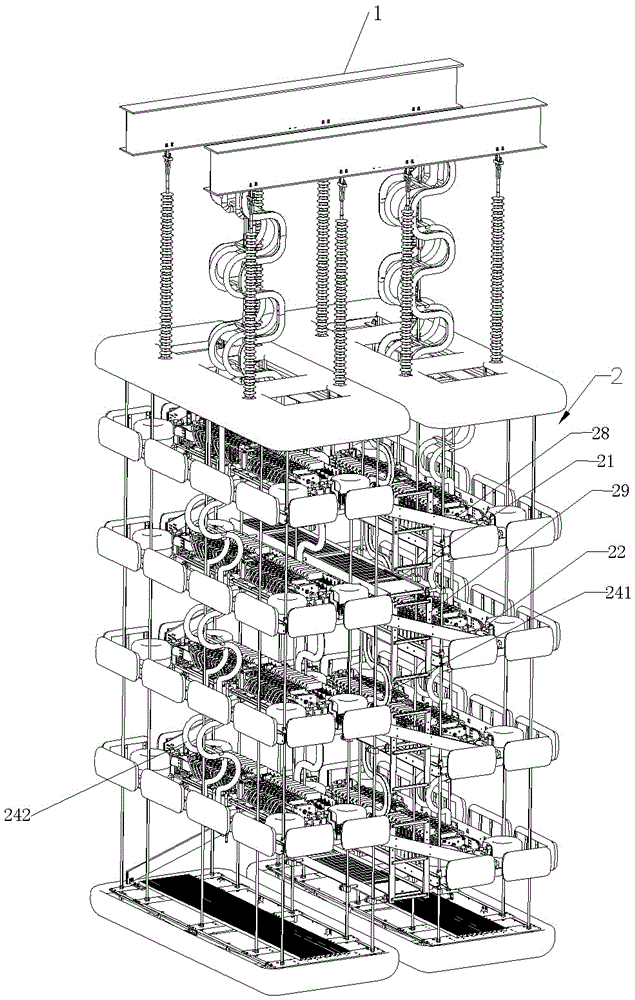

[0021] Embodiment 1 of the valve hall of the present invention, such as Figure 1-2 As shown: the valve hall includes a steel beam 1 and a converter valve tower 2, and the converter valve tower 2 is suspended under the steel beam 1.

[0022] The diverter valve tower 2 includes two rows of diverter valve assemblies arranged at intervals on the left and right, and an inspection platform 21 is provided between the two rows of diverter valve assemblies, and there are two diverter valve assemblies 22 in each row of diverter valve assemblies. The above and from top to bottom are arranged in layers, and two rows of converter valve assemblies are arranged in staggered layers, wherein any converter valve assembly on one row of converter valve assemblies is in the same position as any converter valve assembly on the other row of converter valve assemblies. different heights.

[0023] In order to facilitate the adjustment of the installation distance between adjacent converter valve ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com